Axial Fans Vs Air Movers: What Is the Differences

Axial fans and air movers differ in airflow direction and application. Axial fans move air linearly, while air movers provide high-volume airflow.

Read More

Axial fans and inline fans differ in design, performance, and application. Axial fans are best for moving large volumes of air in open spaces, while inline fans excel in ducted systems with higher resistance. The choice between them depends on specific requirements for airflow, pressure, noise levels, and energy efficiency.

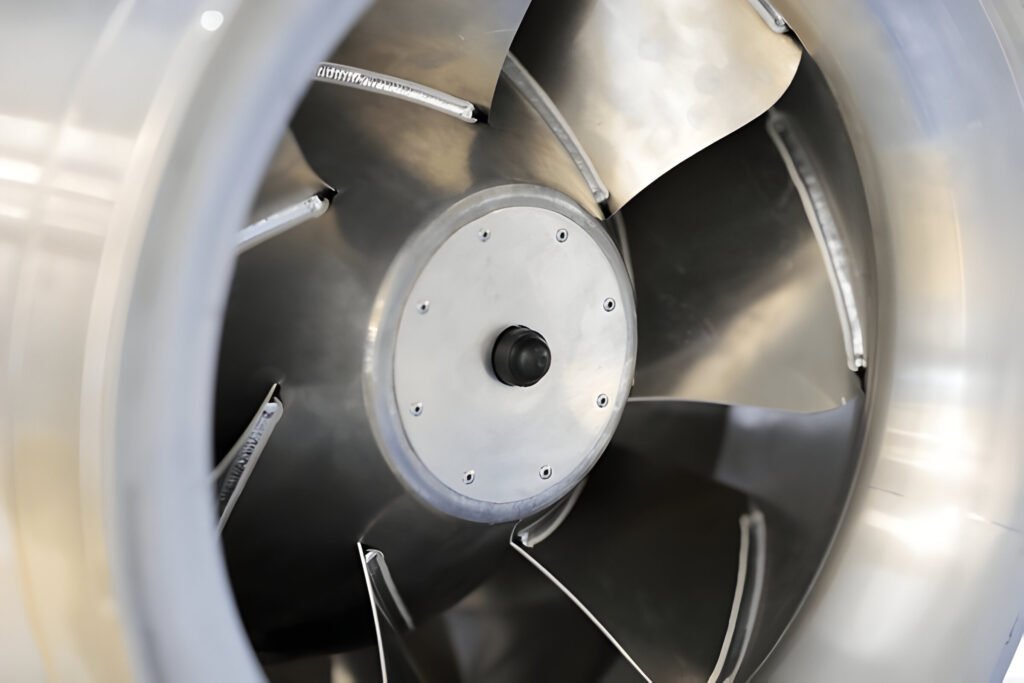

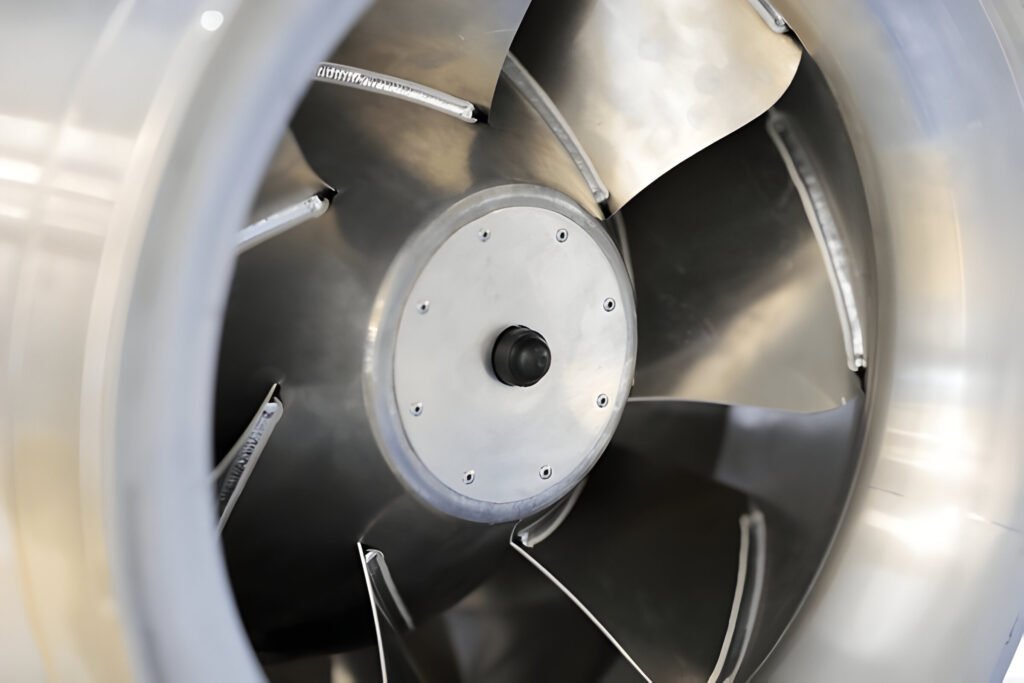

Axial fans move air parallel to their blade rotation axis. A cylindrical housing contains a central hub with attached blades. Spinning blades create pressure differences, pushing air through the fan linearly. These fans excel at moving high air volumes with low pressure. They offer simplicity, efficiency, and high airflow capacity.

Axial fans excel at moving large air volumes efficiently. Their design enables high airflow rates while consuming less energy than other fan types.

Axial fans consume minimal power while moving large air volumes. Their straightforward design allows smooth airflow with reduced resistance, enhancing efficiency.

Inline fans are cylindrical devices that push air through ducts or pipes. They install directly within ductwork, creating a streamlined airflow path.

The compact design of inline fans houses the motor and impeller inside a cylindrical casing. This configuration allows for seamless integration into existing ductwork without major modifications. Inline fans can be mounted horizontally, vertically, or at an angle, offering versatile installation options.

Centrifugal inline fans excel in applications requiring low to medium airflow against pressure. These fans utilize a rotating impeller to accelerate air radially, converting kinetic energy into pressure. They outperform axial fans when handling higher static pressures and operate more quietly.

Centrifugal inline fans typically range from 100 to 1000 cubic feet per minute (CFM) in airflow capacity. They can generate static pressures up to 2 inches of water column (in. wc).

Mixed flow inline fans combine axial and centrifugal designs for medium to high airflow and pressure applications. These fans feature angled blades that push air in a spiral pattern, offering a balanced solution between efficiency and performance.

Mixed flow inline fans surpass axial fans in efficiency. They combine axial and centrifugal fan features, reducing energy consumption while maintaining high performance.

Mixed flow designs offer superior efficiency due to their unique blade configuration. The blades are angled to direct airflow both axially and radially, enhancing air movement and pressure generation. This design minimizes turbulence and energy loss, resulting in improved overall fan efficiency.

Inline fans excel in applications requiring longer duct runs or complex bending configurations. These fans maintain consistent airflow and pressure over extended distances, outperforming axial fans in such setups.

Inline fans operate more quietly than axial fans. Decibel levels for inline fans typically range from 20 to 40 dB, compared to 40 to 60 dB for axial fans of similar capacity.

Axial fans move large air volumes in open spaces, pushing air straight through blades.

Inline fans handle higher static pressure, making them suitable for ducted systems and air movement through obstacles. They maintain efficiency when faced with resistance, though they may move less air than axial fans in open spaces.

Inline fans, particularly centrifugal models, produce higher static pressure than axial fans. This capability allows inline fans to effectively push air through ductwork, filters, and other obstacles.

Axial fans generate lower pressure but excel at moving large volumes of air in open spaces with minimal resistance.

Axial fans generate more noise due to their propeller-like blades. Air moves directly through the fan, creating turbulence and vibrations.

Centrifugal fans use a wheel or impeller to draw air in and redirect it at a 90-degree angle. This smoother airflow path reduces turbulence and noise.

Inline fans outperform axial fans in energy efficiency, especially mixed flow designs. Inline fans move air in a straight line, reducing turbulence and energy loss. They maintain higher static pressures, overcoming more resistance in ducting systems. This results in lower power requirements for the same air volume, reducing energy consumption and operating costs.

Mixed flow inline fans enhance efficiency further. Their blade design allows smoother airflow transitions, minimizing energy loss. These fans achieve higher air volumes at lower speeds, saving energy and operating more quietly.

Inline fans are typically superior for hydroponic systems due to their greater power and efficiency. They provide enhanced air circulation and humidity control. Axial fans may suffice for smaller setups requiring less airflow.