Pulse Width Modulation for DC Motor

Control DC motor speed and torque efficiently using Pulse Width Modulation (PWM) technique.

Read More

Brushless and brushed DC motors are two distinct types of electric motors. While both convert electrical energy into mechanical energy, they differ significantly in their design, efficiency, and performance characteristics.

In this blog post, we will delve into the intricacies of brushless and brushed DC motors, exploring their inner workings, comparing their strengths and weaknesses.

Brushed DC motors, one of the simplest types of electric motors, consist of several key components that enable them to convert electrical energy into mechanical energy.

At the heart of a brushed DC motor is the armature, which is a rotating part made up of coils of wire wound around an iron core. The armature is mounted on a shaft that rotates within the motor housing. Surrounding the armature is the stator, which is the stationary part of the motor. The stator consists of permanent magnets that create a stationary magnetic field.

Another crucial component of a brushed DC motor is the commutator, which is a mechanical switch made up of metal bars or segments mounted on the armature shaft. The commutator is responsible for reversing the current flow in the armature coils as the motor rotates, allowing for continuous rotation.

Electrical contacts called brushes, typically made of carbon or graphite, press against the commutator to supply electrical current to the armature windings.

The working principle of a brushed DC motor relies on the interaction between the magnetic fields generated by the permanent magnets in the stator and the electromagnetic fields created by the current flowing through the armature windings. When a DC voltage is applied to the motor, current flows through the brushes and commutator into the armature coils. This current creates an electromagnetic field around the armature windings, which interacts with the permanent magnetic field of the stator.

The interaction between these two magnetic fields generates a torque that causes the armature to rotate. As the armature spins, the commutator continuously switches the direction of the current flow in the armature coils, ensuring that the torque is always in the same direction. This process of mechanical commutation allows the motor to maintain continuous rotation as long as electrical power is supplied.

Brushed DC motors offer several advantages that make them suitable for various applications:

Despite their advantages, brushed DC motors also have some inherent drawbacks:

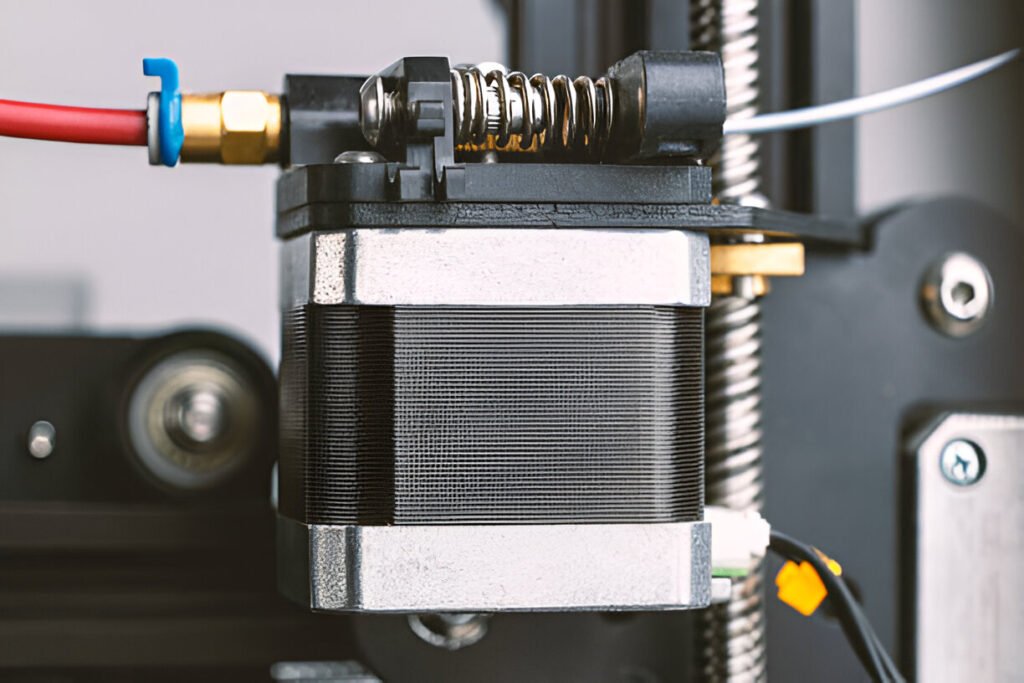

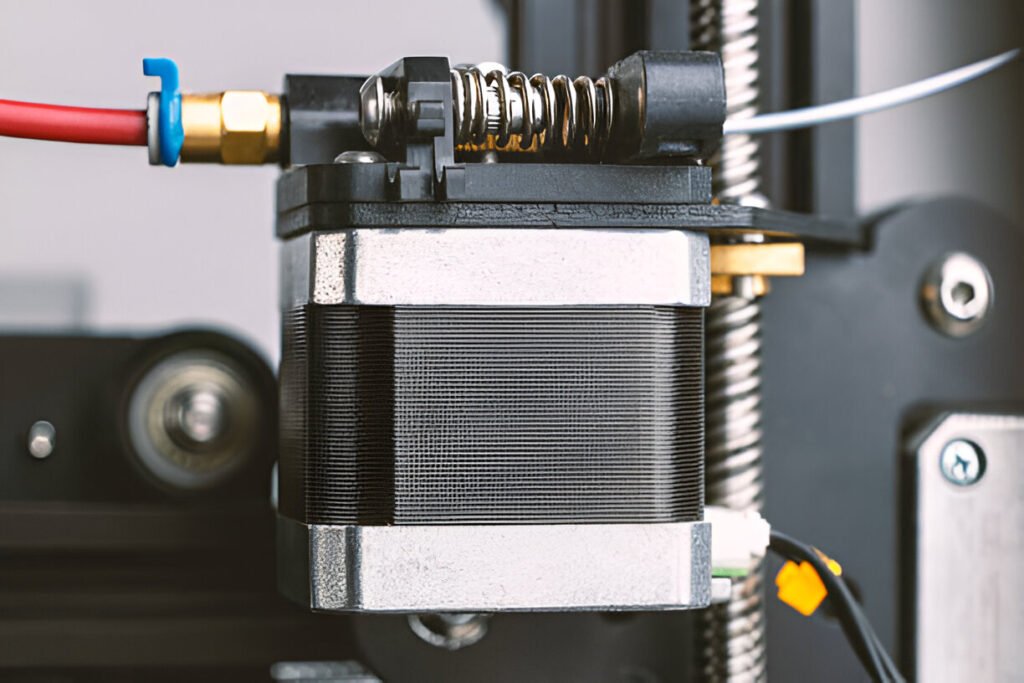

Brushless DC (BLDC) motors are a type of electric motor that uses permanent magnets in the rotor and electromagnets on the stator.

The stator consists of a series of coils arranged in a specific pattern, which creates a rotating magnetic field when energized. The rotor, made up of permanent magnets, follows this rotating field, causing the motor shaft to turn.

Hall-effect sensors or an optical encoder are used to determine the position of the rotor, enabling precise control of the motor’s speed and torque.

In a brushless DC motor, the commutation process is controlled electronically, eliminating the need for physical brushes and a mechanical commutator. The electronic controller supplies current to the appropriate stator windings based on the rotor’s position, creating a rotating magnetic field. This field interacts with the permanent magnets on the rotor, causing it to rotate and generate torque.

By adjusting the winding currents, the speed and torque of the motor can be precisely controlled. This process, known as electronic commutation, allows for smooth operation and enhanced efficiency compared to brushed DC motors.

Brushless DC motors offer several advantages over their brushed counterparts:

Despite their numerous benefits, brushless DC motors also have some drawbacks:

One of the most significant advantages of brushless DC motors over brushed DC motors is their higher efficiency. BLDC motors typically offer 85-90% efficiency, while brushed DC motors generally achieve 75-80% efficiency.

Brushless DC motors have a longer lifespan and require less maintenance compared to brushed DC motors.

In a brushed motor, the brushes and commutator are subject to wear and tear due to constant physical contact and sparking during operation. This leads to the need for periodic maintenance, such as brush replacement and commutator cleaning.

In contrast, BLDC motors do not have brushes or a commutator, eliminating these wear points and extending the motor’s service life. The absence of brushes also means that BLDC motors can operate in cleaner environments without the risk of brush dust contamination.

Brushless DC motors offer a wider range of speed and torque characteristics compared to brushed DC motors.

BLDC motors can achieve high speeds, often exceeding 10,000 RPM, while maintaining a constant torque output over a broad speed range. This is due to their electronic commutation, which allows for precise control of the magnetic fields in the motor.

In contrast, brushed DC motors typically have a more limited speed range and experience a drop in torque at higher speeds due to the mechanical limitations of the brushes and commutator.

For a given power output, brushless DC motors are generally smaller and lighter than brushed DC motors.

The absence of brushes and a commutator allows for more compact motor designs, as the space previously occupied by these components can be used for additional windings or magnets.

Brushed DC motors generate more electrical noise compared to brushless DC motors.

The sparking that occurs between the brushes and commutator in a brushed motor creates electromagnetic interference (EMI), which can affect nearby electronic devices and sensitive circuits.

BLDC motors, on the other hand, produce significantly less electrical noise due to their electronic commutation and the absence of brushes.

Brushless DC motors generally produce less acoustic noise and have lower torque ripple compared to brushed DC motors.

The absence of brushes and a commutator in BLDC motors eliminates the mechanical noise generated by these components. Additionally, the smooth electronic commutation in BLDC motors results in a more consistent torque output, reducing torque ripple.

In contrast, brushed DC motors may exhibit higher levels of acoustic noise and torque ripple due to the mechanical commutation process and the interaction between the brushes and commutator.

Brushless DC motors typically have lower vibration levels compared to brushed DC motors.

The absence of brushes and a commutator in BLDC motors reduces the mechanical imbalances and irregularities that can cause vibrations. The electronic commutation in BLDC motors also allows for smoother operation and better control of the motor’s rotation, further minimizing vibrations.

In brushed DC motors, the mechanical commutation process and the wear of brushes and commutator can contribute to higher vibration levels.

Controlling brushless DC motors is more complex compared to brushed DC motors.

BLDC motors require an electronic controller to perform the commutation process, which involves precisely switching the current in the motor windings based on the rotor position. This requires additional components such as Hall-effect sensors or an optical encoder to determine the rotor position.

In contrast, brushed DC motors have a simpler control system, as the commutation is performed mechanically by the brushes and commutator. This makes brushed DC motors easier to control and less dependent on complex electronics.

Brushless DC motors generally have a higher initial cost compared to brushed DC motors.

The complex electronic controller, sensors, and advanced manufacturing processes required for BLDC motors contribute to their higher price point. However, the long-term cost of ownership for BLDC motors can be lower due to their higher efficiency, longer lifespan, and reduced maintenance requirements.

Brushed DC motors, while cheaper upfront, may incur additional costs associated with brush and commutator replacements, as well as reduced efficiency and shorter service life.

Brushed motors are generally cheaper than brushless motors due to their simpler construction and fewer components.

They consist of a commutator, brushes, an armature, and permanent magnets. The brushes and commutator are subject to wear, but these components are inexpensive to manufacture. Additionally, brushed motors do not require complex electronic speed controllers, further reducing costs.

Brushless motors typically last longer than brushed motors. The absence of brushes and a commutator in brushless motors eliminates the primary wear components found in brushed motors. This reduction in wear allows brushless motors to operate for extended periods without maintenance. However, proper care and usage conditions can extend the life of both motor types.