Product Introduction

T35-11 (FBT35-11) axial flow fan can be connected to the middle of the pipeline as part of the pipeline. It is suitable for conveying air below 60 degrees and various gases that are harmful to motors in factories such as chemical and papermaking.

The fan is divided into five machine numbers according to the diameter of the impeller, namely NO6, 7, 8, 9, and 10. The blades are available in four and six pieces. The blade installation angle can be made into 15 degrees, 20 degrees, 25 degrees, and 30 degrees. The motor is installed on the upper part of the wind tube. The motor seat is movable, supporting the motor, and the center distance is adjustable. All are driven by V-belts. The bearing box is fixed in the protective cylinder sealed in the center of the wind tube and isolated from the medium.

This type of fan is generally made of welded steel plates. If it contains corrosive and flammable gases, special manufacturing can be requested when ordering.

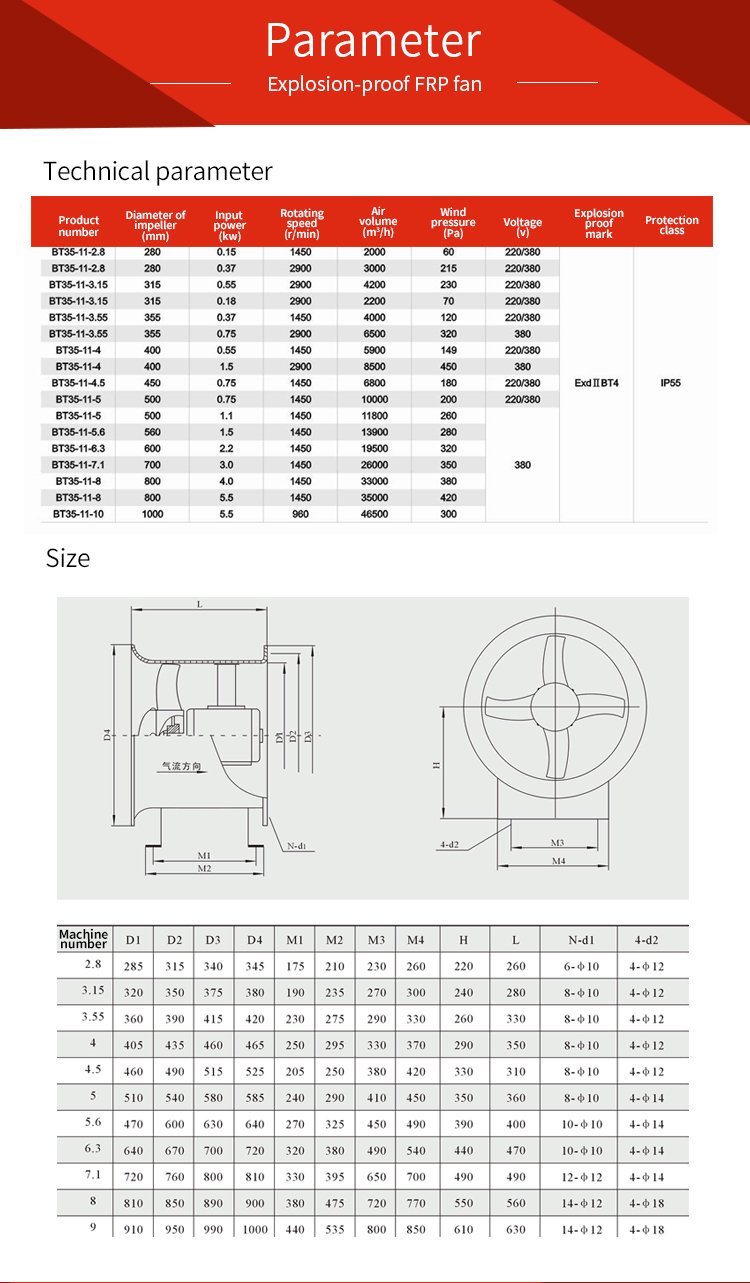

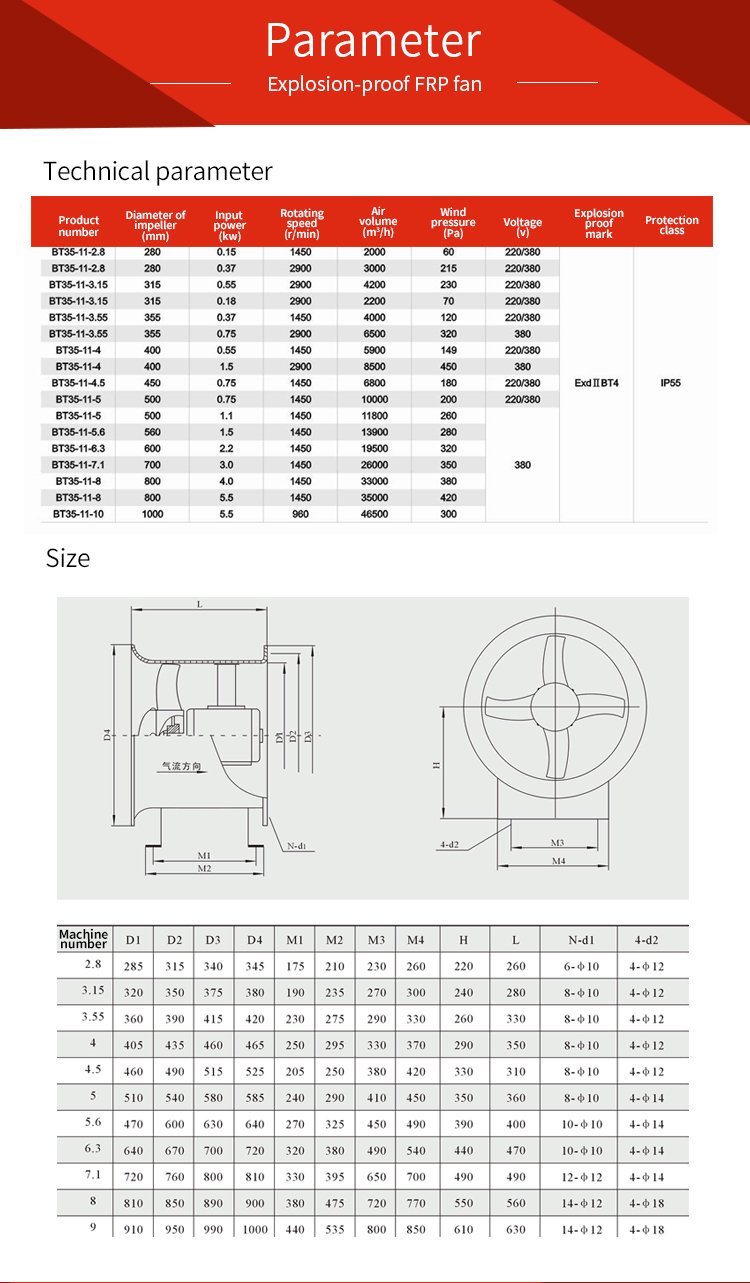

Main technical parameters of T35-11 axial flow fan:

| No. | Impeller diameter (mm) | Speed (rpm) | Air volume (m3/h) | Total pressure (Pa) | Equipped motor power (kw) |

| 2.8 | 280 | 2900 | 1506-3059 | 143.0-216.7 | 0.12/0.18/0.25/0.37 |

| 1450 | 753-1529 | 35.7-54.1 | 0.025/0.04 | ||

| 3.15 | 315 | 2900 | 2144-4356 | 181-274.3 | 0.18/0.25/0.37/0.55 |

| 1450 | 1072-2178 | 45.2-68.5 | 0.025/0.04/0.06/0.09 | ||

| 3.55 | 355 | 2900 | 3069-6235 | 230.0-348.4 | 0.37/0.55/0.75/1.1 |

| 1450 | 1534-3117 | 57.5-87.1 | 0.04/0.06/0.09/0.12 | ||

| 4 | 400 | 2900 | 4391-8920 | 292.0-442.4 | 0.55/1.1/1.5/2.2 |

| 1450 | 2195-4460 | 73.0-110.6 | 0.09/0.12/0.18/1.25 | ||

| 4.5 | 450 | 1450 | 3126-6350 | 92.3-139.9 | 0.18/0.25/1.37/0.55 |

| 5 | 500 | 1450 | 4288-8711 | 114.0-172.8 | 0.25/0.37/0.55/0.75 |

| 2900 | 2839-5765 | 49.9-75.7 | 0.37 | ||

| 5.6 | 560 | 1450 | 6025-12239 | 143.0-216.7 | o.37/0.55/0.75/1.1/1.5 |

| 960 | 3989-8190 | 62.7-95.0 | 0.37 | ||

| 6.3 | 630 | 1450 | 8579-17426 | 181.0-274.3 | 0.75/1.1/1.5/2.2 |

| 960 | 5879-11537 | 79.3-120.2 | 0.37/0.75 | ||

| 7.1 | 710 | 1450 | 12279-24943 | 230.0-348.4 | 1.5/2.2/3/4 |

| 960 | 8130-16514 | 108.0-152.7 | 0.75/1.1 | ||

| 8 | 800 | 1450 | 17566-35682 | 292.0-442.4 | 2.2/4/5.5/7.5 |

| 960 | 11630-23624 | 127.9-193.9 | 0.75/1.1/1.5/2.2 | ||

| 9 | 900 | 960 | 16559-33636 | 162.9-245.4 | 1.5/2.2/3/4 |

| 10 | 1000 | 960 | 22715-46141 | 199.9-303.0 | 2.2/3/4/7.5 |

| 11.2 | 1120 | 960 | 31913-64824 | 250.8-380.1 | 4/5.5/7.5/11 |

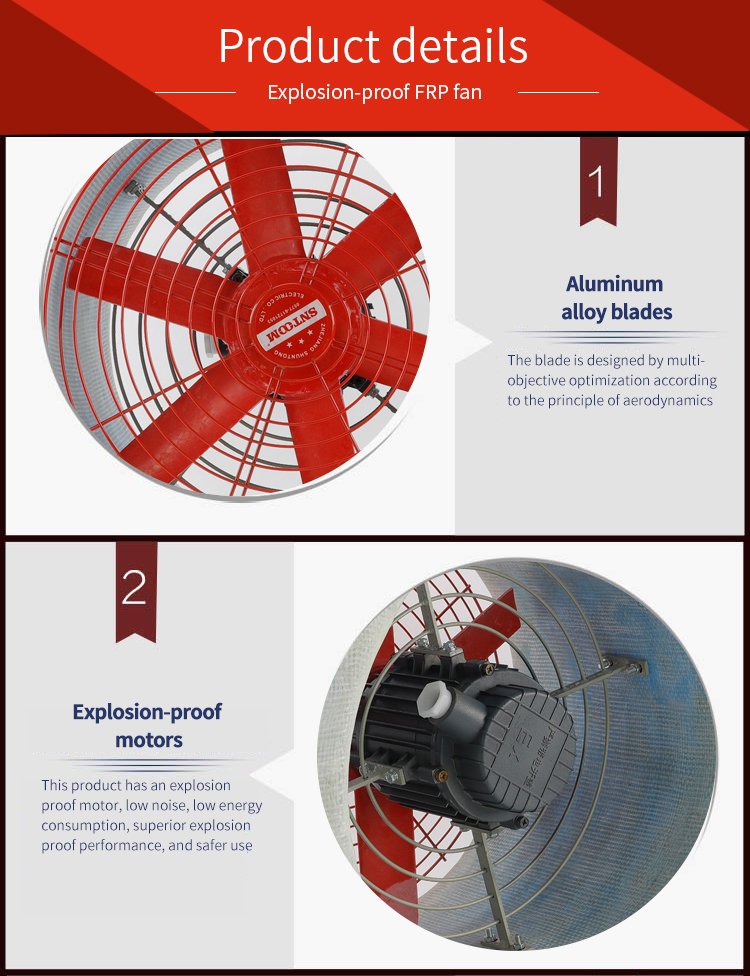

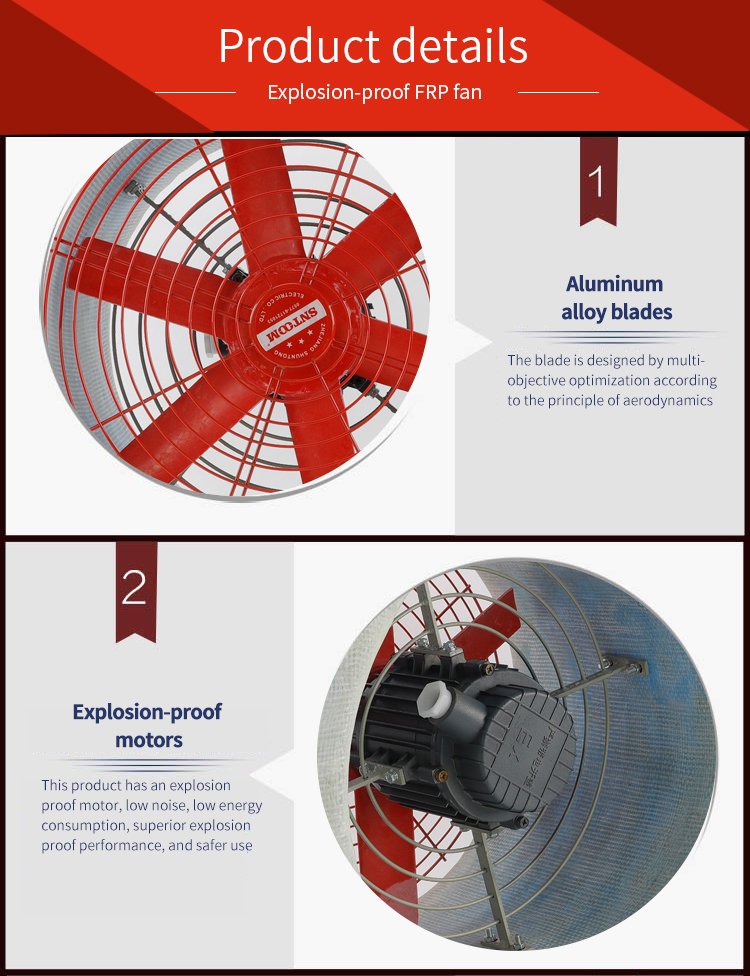

Product Features

- Efficient ventilation and air exchange: The T35 axial flow fan is designed to quickly and effectively achieve air circulation and exchange in spaces, suitable for various places such as factory workshops, warehouses, offices, etc., effectively eliminating polluted air, introducing fresh air, and maintaining indoor air quality.

- Wide applicability: Provides a variety of models and specifications to choose from, including impellers of different diameters and adjustable installation angles (such as 15 ° to 35 °), to adapt to different spatial structures and ventilation needs, ensuring the best ventilation effect and energy efficiency ratio.

- Low noise operation: Adopting advanced noise reduction design, such as optimizing blade shape and motor structure, significantly reduces the noise generated during operation, providing a comfortable ventilation experience for places that require a quiet environment, such as libraries and hospitals.

- Energy saving and efficient: Through model experiments, the optimized design of the fan blades and motor system, T35 axial flow fan, while ensuring high air output, reduces energy consumption, improves overall efficiency, and meets the energy-saving requirements of modern green buildings.

- Easy to install and maintain: The structural design is compact, easy to install, and convenient for users to flexibly arrange according to site conditions. Meanwhile, the daily maintenance and cleaning of the fan are relatively simple, which helps to extend the service life of the equipment and reduce maintenance costs.

Installation instructions:

- Before installation, please check the fan in detail for damage or deformation. If there is damage or deformation, it should be repaired before installation.

- During installation, pay attention to check whether the connection parts are loose. The gap between the blades should be uniform and should not touch each other.

- The weight of the air duct connected to the air outlet should not be borne by the fan coil of the fan. A support frame should be added during installation.

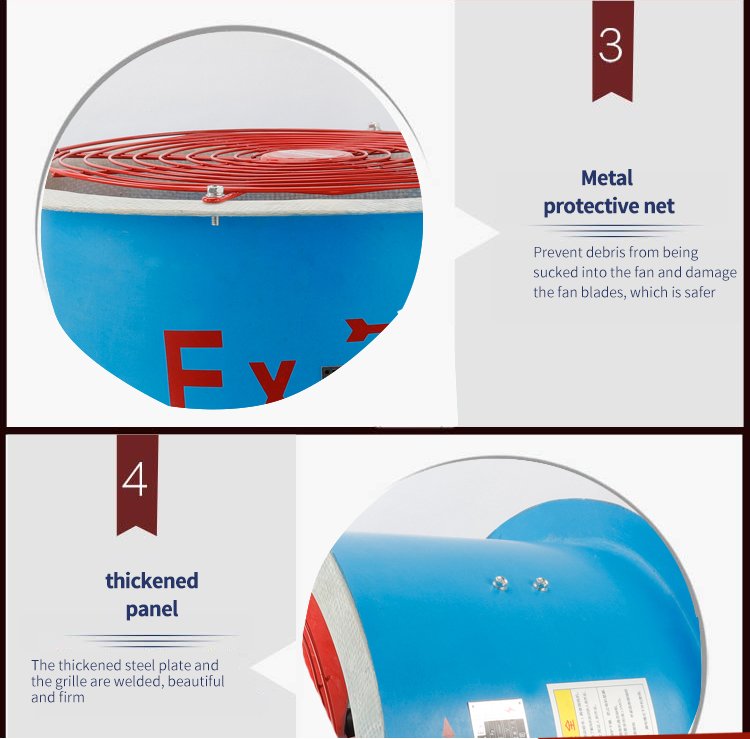

- A wind collector should be installed at the outlet of the fan, and a protective net should be installed.

- The fan base must naturally engage with the ground plane. The base should not be knocked to force the connection to prevent deformation of the base. During installation, the base should be corrected, the iron should be used to maintain a horizontal position, and the anchor bolts should be tightened.

- After installation, a test should be carried out first, and it is allowed to be officially used only after normal operation.

Product images

Request a Quote Now

Our team will get back to you within 24 hours.