The SNTOOM variable frequency drive is an advanced, all-in-one solution designed to optimize motor control. It boasts features like multi-mode regulation, energy savings, and stepless speed adjustment, ensuring precise and efficient operation. With a robust design, protective motor functions, and an intuitive LED interface, it offers reliable performance across various industries, enhancing productivity while reducing energy consumption.

Application environment

This variable frequency drive, with its wide operating speed range and intelligent control capabilities, is ideal for diverse environments. It excels in plastic machinery, textile equipment, and packaging industries, ensuring precise motor speed regulation. The drive’s energy-saving features and stable performance make it suitable for applications requiring constant pressure water supply and emission reduction, enhancing production efficiency across various sectors.

Product parameters

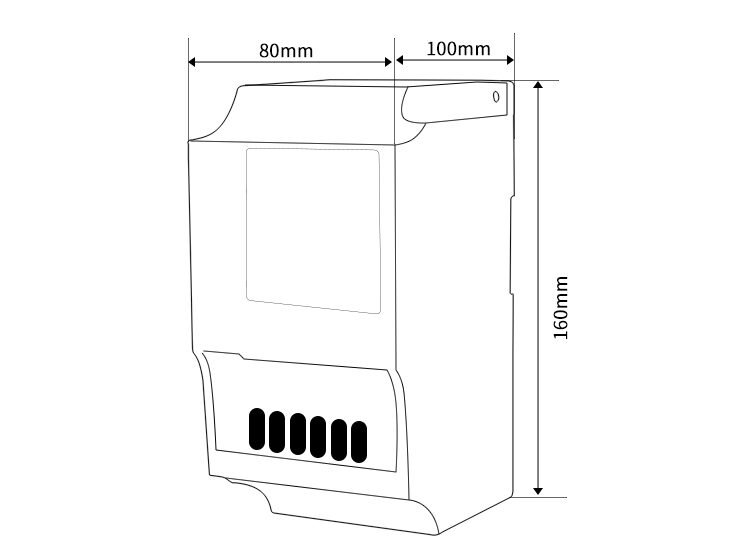

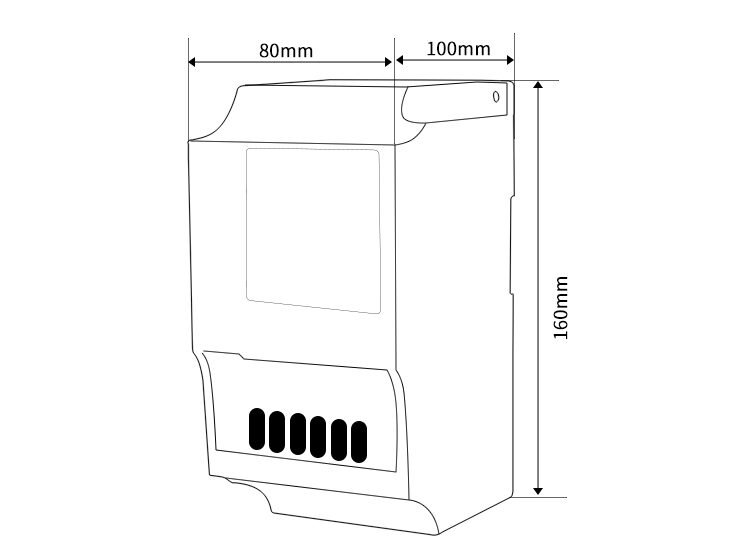

| Product Series | Product Name | Applicable Industries | Product Power | Product Dimensions |

| V811AO-4T0007G-E V811AO-4T0015GE V811AO-4T0022G-E | Vector frequency converter | Plastic machinery, wire and cable, and packaging, textile machinery, drawing machine, and all mechanical equipment that uses motors | 0.75KW, 1.5KW, 22KW (380V) 0.4KW, 0.75KW, 1.5KW (220V) | 160MM / 83MM / 100MM |

Dimension

Product Features

- This variable frequency drive (VFD) combines multiple functions into one compact unit, offering features like multi-mode regulation, energy saving, and step-less speed regulation. It ensures convenient operation and protects motors effectively, making it ideal for various industrial applications.

- Designed for energy-saving and power-saving operations, this VFD helps reduce electricity consumption and operational costs. Its intelligent control allows for optimized performance, ensuring that motors run at peak efficiency while minimizing energy waste.

- With a flexible control interface, this VFD is easy to adjust and operate. It features a PLC torque speed control mode and supports a frequency range of 0-400Hz. The LED display provides an intuitive interface, enhancing user experience and operational efficiency.

- Equipped with a smart chip and thickened three-proof coating design, this VFD ensures stable performance under various environmental conditions. It is moisture-proof, anti-static, and built to last, offering a 2-year warranty for added reliability.

- This VFD is suitable for a wide range of industries, including plastic machinery, textile machinery, and equipment requiring constant pressure water supply. It achieves precise motor speed regulation, energy savings, and emission reduction, improving overall production efficiency.

- Featuring a composite flame-retardant plastic casing and built-in cooling fan, this VFD is designed for durability and long service life. The EPCOS electrolytic capacitor ensures stable charging and discharging, while the compact design allows for easy installation in tight spaces.

Product installation and instructions

- Begin by selecting a suitable location for installation, ensuring it’s dry, well-ventilated, and free from excessive dust or corrosive gases. Then, securely mount the on a stable surface using appropriate fasteners.

- First, check the power supply requirements of the frequency converter. Connect the input power cables correctly to the designated terminals, ensuring proper insulation and tight connections. Then, connect the motor cables to the output terminals of the converter.

- Prior to installation, disconnect all power sources. Connect the control wires according to the wiring diagram provided, connecting input signals such as start/stop and speed reference to the corresponding control terminals of the frequency converter.

- After completing the wiring, double-check all connections for accuracy and tightness. Then, restore the power supply and perform initial setup and testing as per the user manual, adjusting parameters as needed for your specific application.

Note:This variable frequency drive should be operated within specified frequency and load ranges. Avoid using in damp or extreme temperature environments and prevent overvoltage.

Request a Quote Now

Our team will get back to you within 24 hours.