Induction vs DC Brushless: What Is The Difference

Discover the key differences between induction and DC brushless motors in this comprehensive comparison guide.

Read More

Brushless DC motors have revolutionized the world of motion control, offering superior efficiency, reliability, and performance compared to their brushed counterparts.

In this blog post, we will delve into the intricacies of brushless DC motors, exploring their unique design, operating principles, and the numerous advantages they bring to the table.

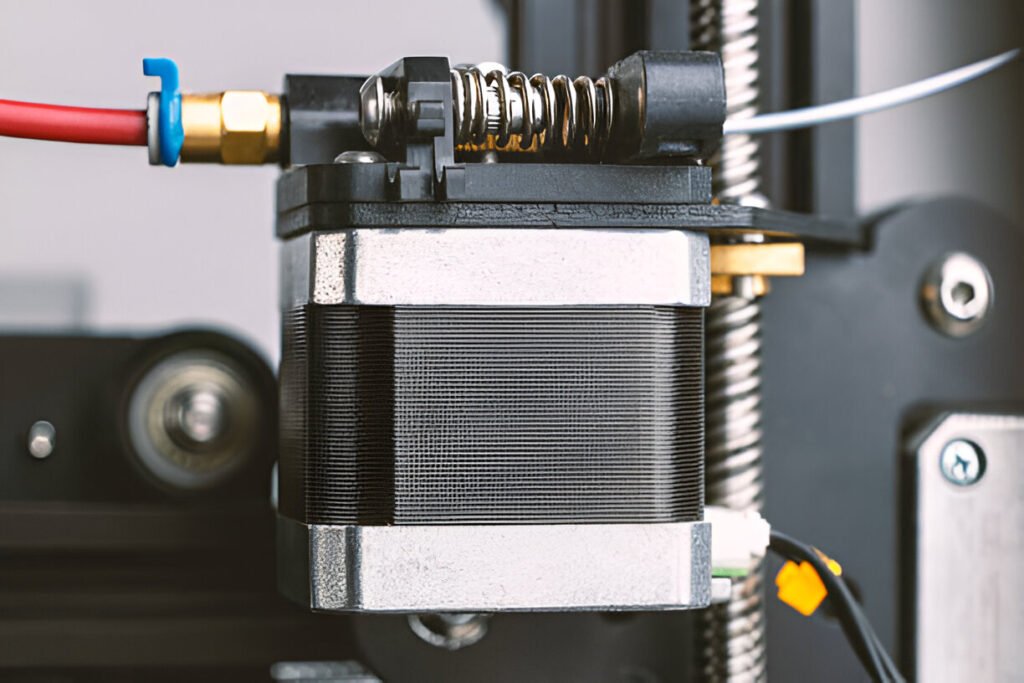

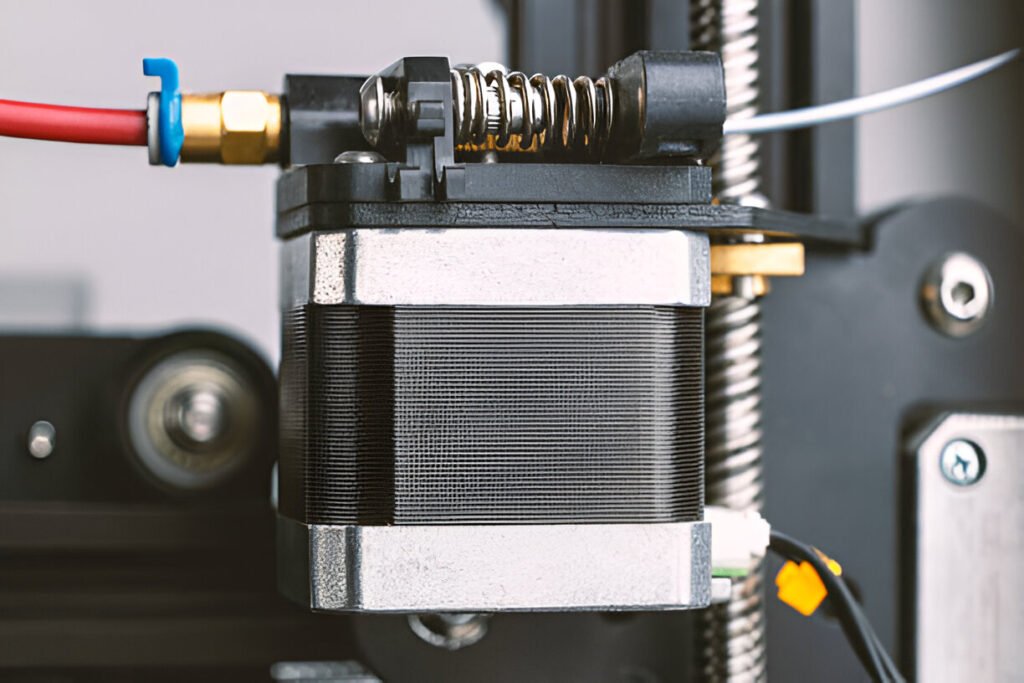

Brushless DC (BLDC) motors are a type of synchronous electric motor that has gained popularity in recent years due to their high efficiency, reliability, and precise control capabilities. Unlike traditional brushed DC motors, BLDC motors utilize electronic commutation instead of a mechanical commutator and brushes, resulting in a more compact motor structure and reduced maintenance requirements.

Brushless DC (BLDC) motors are composed of several key components that work together to enable efficient and precise operation. The main components of a BLDC motor include the stator with wound coils, the rotor with permanent magnets, and the electronic controller with sensors.

The stator is the stationary part of the BLDC motor and consists of a series of electromagnetic coils arranged in a specific pattern. These coils are typically made of copper wire and are wound around iron cores to form the stator windings.

When electrical current passes through these coils, they generate a magnetic field that interacts with the permanent magnets on the rotor, causing the rotor to rotate.

The rotor is the rotating part of the BLDC motor and is composed of permanent magnets. The interaction between the permanent magnets on the rotor and the electromagnetic field generated by the stator coils causes the rotor to rotate.

The electronic controller, also known as an electronic speed controller (ESC), is responsible for regulating the power supply to the stator coils and controlling the motor’s speed and direction. It uses pulse-width modulation (PWM) to generate the necessary electrical signals to drive the motor.

Sensors, such as Hall effect sensors or encoders, are used to detect the rotor’s position and provide feedback to the electronic controller. This feedback allows the controller to determine the appropriate sequence and timing of electrical pulses to be sent to the stator coils, ensuring smooth and efficient operation.

BLDC motors can be designed in two main configurations: inrunner and outrunner.

In an inrunner configuration, the rotor is located inside the stator, and the permanent magnets are mounted on the rotor’s surface. This design allows for a compact motor structure and is commonly used in applications requiring high speeds and low torque.

An outrunner configuration has the rotor located outside the stator, with the permanent magnets mounted on the inner surface of the rotor. This design provides a larger rotor diameter, allowing for higher torque output and lower speeds. Outrunner BLDC motors are often used in applications such as drones, electric vehicles, and industrial automation.

The working principle of brushless DC (BLDC) motors relies on the precise control of electromagnetic coils and permanent magnets to generate rotational motion. Unlike brushed DC motors, BLDC motors use electronic commutation instead of a mechanical commutator to control the electric current in the stator windings.

The working principle of BLDC motors can be summarized as follows:

Despite their numerous advantages, Brushless DC (BLDC) motors also have some limitations and disadvantages:

There are two main categories of electric motors: AC motors and DC motors.

AC motors, or alternating current motors, are powered by alternating current electricity. They are widely used in various industrial and commercial applications due to their simplicity, reliability, and low maintenance requirements. The most common types of AC motors include:

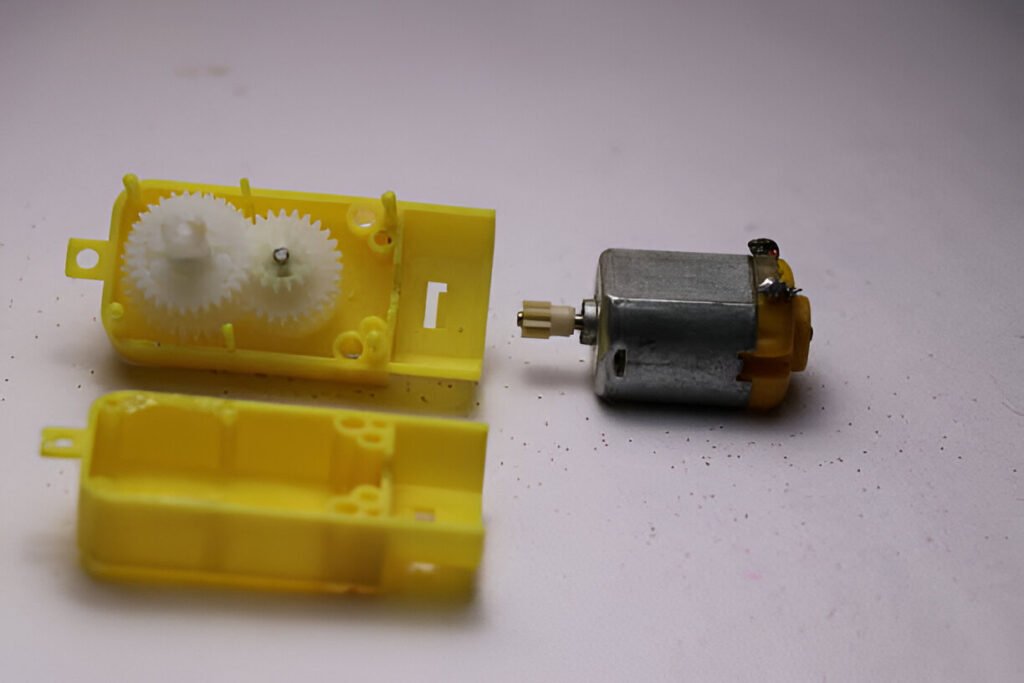

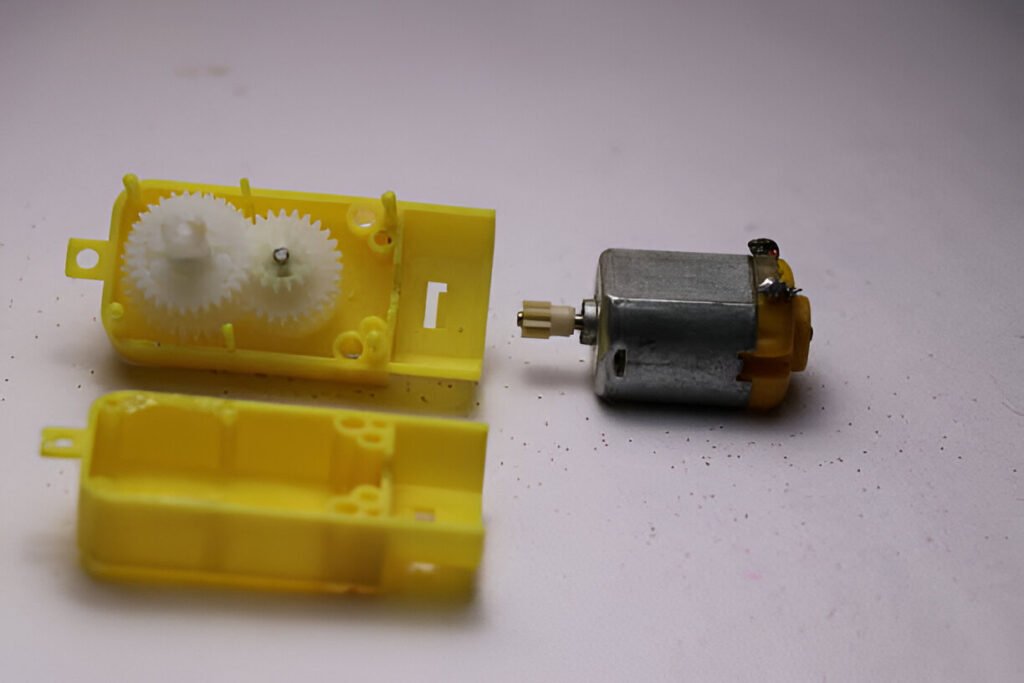

DC motors, or direct current motors, are powered by direct current electricity. They offer excellent speed control, high starting torque, and a wide range of operating speeds. The main types of DC motors include:

Brushless DC (BLDC) motors come in various configurations to suit different applications and requirements.

Single-phase BLDC motors are the simplest type of brushless motor, featuring a single stator winding and a permanent magnet rotor. These motors are typically used in low-power applications, such as small fans and pumps, where precise control and high efficiency are not critical. Single-phase BLDC motors are generally less expensive than their multi-phase counterparts and offer a compact motor structure.

Multi-phase brushless DC motors are the most common type of BLDC motor, with three-phase motors being the most prevalent. These motors feature multiple stator windings, usually arranged in a star or delta configuration, and a permanent magnet rotor. The electronic controller sequentially energizes the stator windings, creating a rotating magnetic field that interacts with the rotor’s permanent magnets, causing the rotor to rotate.

Multi-phase BLDC motors offer higher power density, better torque control, and smoother operation compared to single-phase motors. They are widely used in applications such as electric vehicles, robotics, and industrial automation.

Sensored BLDC motors incorporate position sensors, such as Hall effect sensors or encoders, to provide feedback on the rotor’s position to the electronic controller. This allows for precise control of the motor’s speed, torque, and position.

Sensored BLDC motors are ideal for applications that require high-precision positioning, such as robotics, CNC machines, and medical devices. The additional sensors and wiring can increase the cost and complexity of the motor system, but the improved control and performance often justify the added expense.

Sensorless control BLDC motors eliminate the need for physical position sensors by employing advanced control algorithms to estimate the rotor’s position based on the back-EMF (electromotive force) generated in the stator windings. This reduces the cost and complexity of the motor system while maintaining good performance.

Sensorless control techniques, such as trapezoidal commutation and field-oriented control (FOC), enable the electronic controller to optimize the motor’s performance without the need for additional sensors. Sensorless BLDC motors are commonly used in applications where cost is a concern, and the required level of control can be achieved without physical sensors, such as in HVAC systems, pumps, and fans.

Axial flux BLDC motors feature a unique geometry where the stator and rotor are arranged parallel to each other, with the magnetic flux flowing axially through the motor. This configuration allows for a compact motor structure with a high power density, making axial flux BLDC motors well-suited for applications with limited space, such as electric vehicles and drones.

The axial flux design also enables better heat dissipation, which can improve the motor’s efficiency and lifespan. However, axial flux BLDC motors can be more complex to manufacture and may have a higher cost compared to traditional radial flux motors.

Brushless DC (BLDC) motors find extensive use across various industries due to their high efficiency, precise control, and low maintenance requirements. Some common applications include:

Brushless DC motors require specialized control methods and drive systems to ensure optimal performance and efficiency. The following are some common control techniques used with BLDC motors:

Trapezoidal control, also known as six-step commutation or square-wave control, energizes the motor windings in a sequence that produces a trapezoidal back-EMF waveform. This method is simpler to implement but can result in torque ripple and acoustic noise.

Sinusoidal control, or field-oriented control (FOC), drives the motor with a sinusoidal current waveform that closely matches the back-EMF. This results in smoother torque output, reduced vibration, and quieter operation, but requires more complex control algorithms and higher-resolution position feedback.

FOC is an advanced control technique that decouples the stator current into separate torque-producing and flux-producing components. By independently controlling these components, FOC achieves precise torque, speed, and position control while maximizing efficiency. This method requires accurate rotor position feedback and complex mathematical transformations, making it more computationally intensive than trapezoidal control.

Sensorless control eliminates the need for dedicated position sensors, reducing cost and improving reliability. These techniques estimate the rotor position using the motor’s electrical parameters, such as back-EMF or current ripple. Some common sensorless control methods include: