Different Types of Electric Motors

Explore the various types of electric motors, their working principles, applications, and key differences.

Read More

In a DC motor, brushes are critical components that facilitate the transfer of electrical current from the stationary parts to the rotating armature. These small yet essential elements play a vital role in the motor’s operation, directly impacting its performance and efficiency.

In this blog post, we will delve into the specific functions of brushes in DC motors and explore how they contribute to the overall operation of these widely used devices.

Brushes are critical components in DC motors that enable the transfer of electrical current from the stationary part of the motor (stator) to the rotating part (armature or rotor).

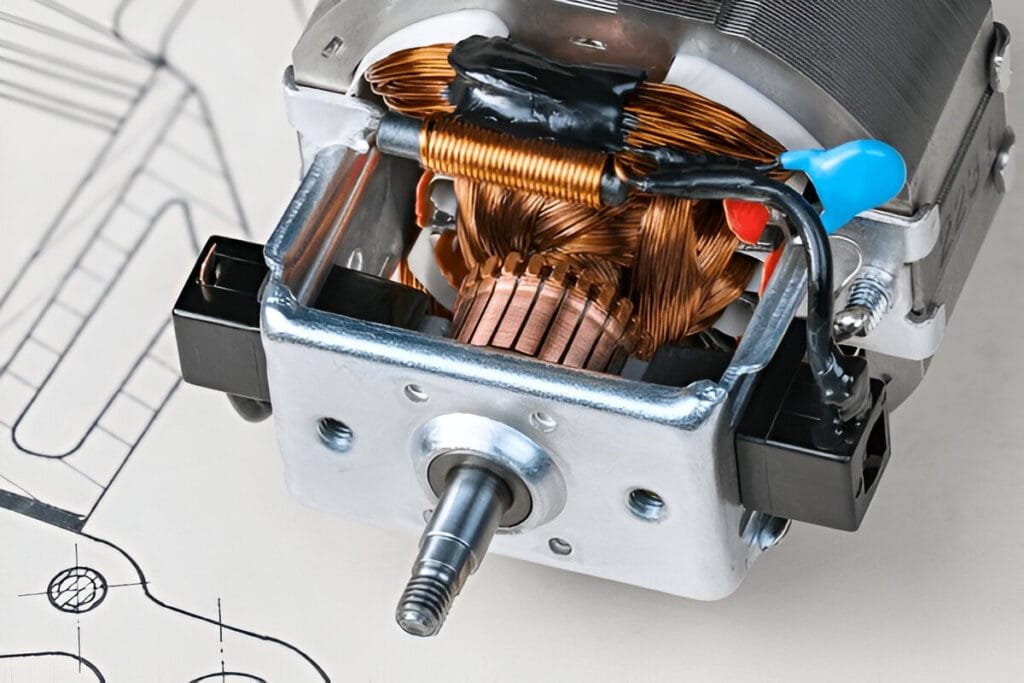

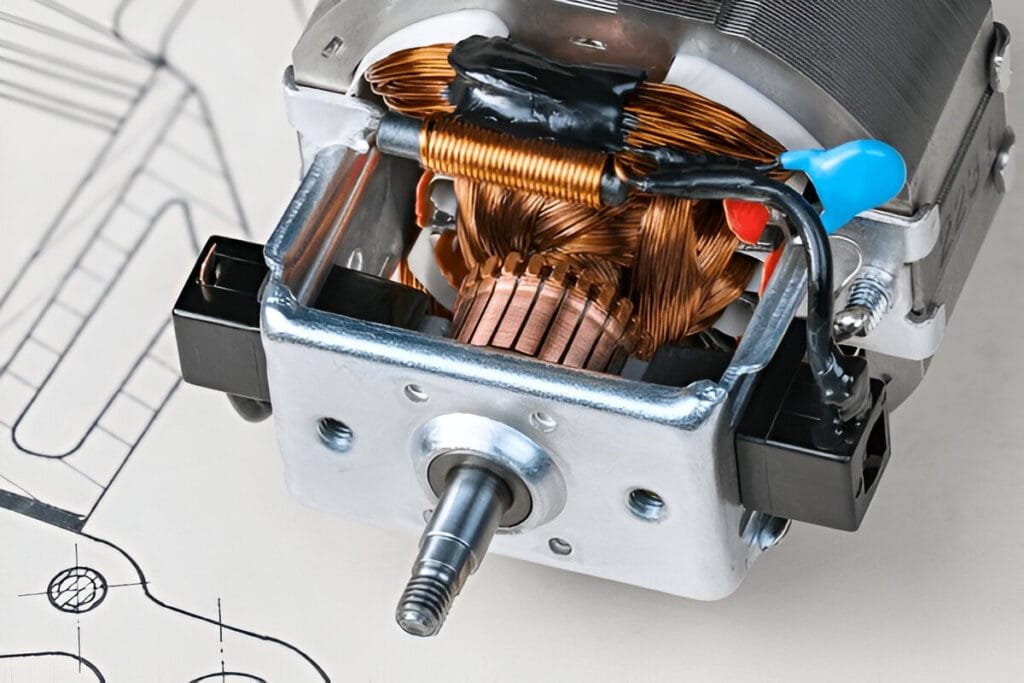

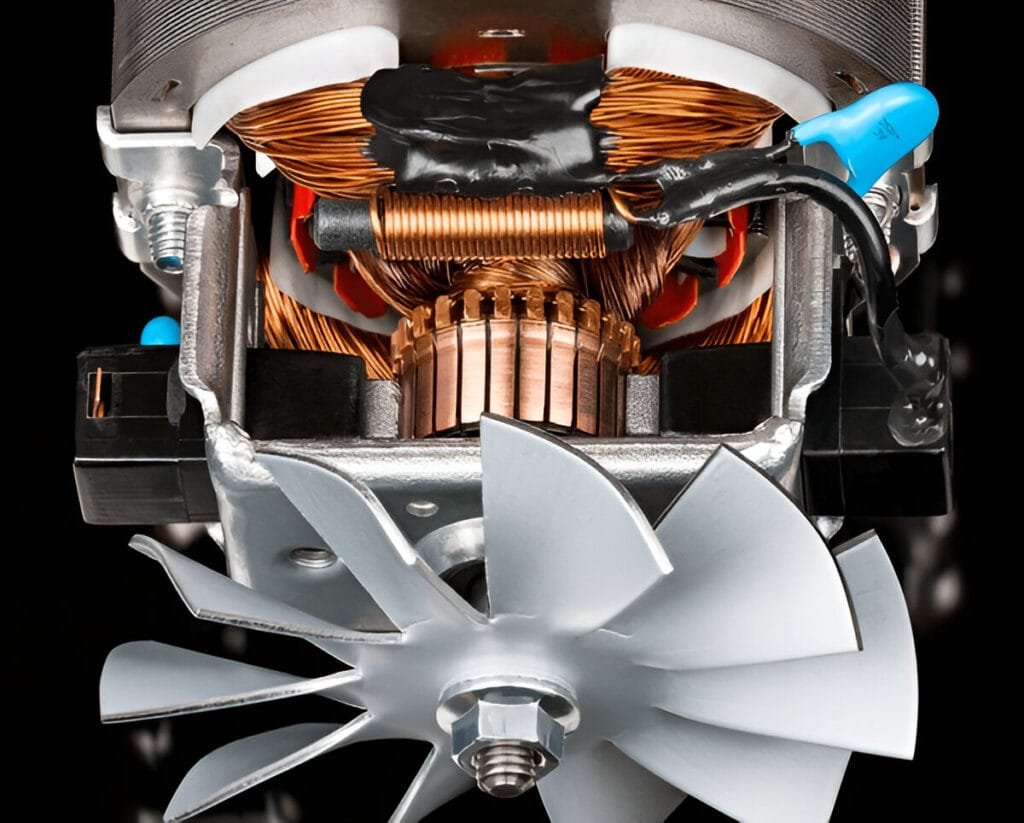

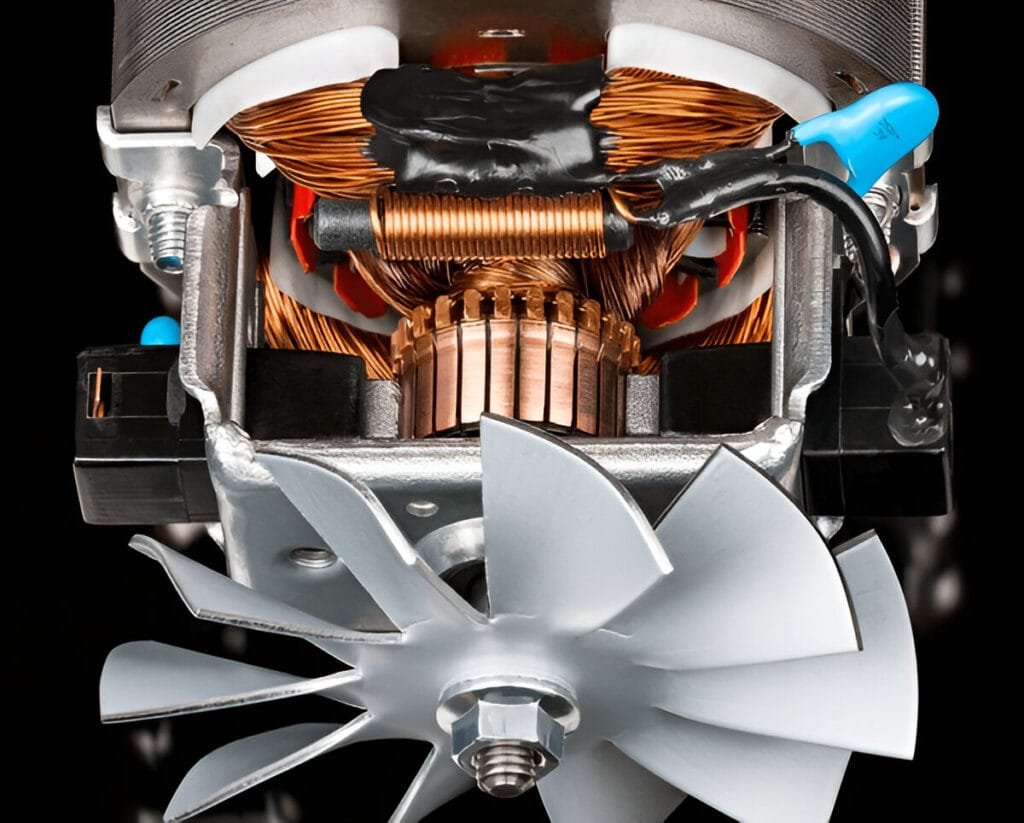

In a brushed DC motor, the brushes are typically made of carbon or graphite and are held in contact with the commutator, a segmented copper ring mounted on the motor shaft.

The primary function of brushes in a DC motor is to form a sliding electrical contact between the external power source and the rotating armature windings. This allows the electrical current to flow from the brushes to the commutator segments, which are connected to the armature coils. As the motor rotates, the brushes maintain contact with different commutator segments, facilitating the continuous flow of current to the appropriate armature windings.

Three common types of brushes used in DC motors are carbon brushes, graphite brushes, and composite brushes.

Carbon brushes are the most widely used type in DC motors due to their cost-effectiveness and versatility. Made from a mixture of carbon, copper, and graphite, these brushes offer good electrical conductivity and are suitable for a wide range of applications. Carbon brushes are particularly effective in low-voltage, low-current motors found in devices such as power tools, automotive starters, and household appliances.

The composition of carbon brushes allows them to maintain continual contact with the commutator while minimizing wear and tear. As the brushes press against the commutator segments, they transfer electrical current from the external power source to the armature windings, enabling the motor to rotate. The presence of copper particles in the brush material enhances conductivity and helps to dissipate heat generated during operation.

However, carbon brushes are prone to wear over time due to friction and may produce carbon dust, which can accumulate inside the motor housing.

Graphite brushes are another popular choice for DC motors, particularly in applications requiring high-speed operation or exposure to elevated temperatures. Made from high-purity graphite, these brushes exhibit excellent electrical conductivity and are more resistant to wear compared to carbon brushes.

The self-lubricating properties of graphite help to reduce friction between the brush and commutator surface, minimizing wear and extending the lifespan of both components. Graphite brushes also have a higher current-carrying capacity than carbon brushes, making them suitable for motors operating at higher voltages and currents.

In addition to their durability and performance benefits, graphite brushes generate less electromagnetic noise during operation compared to carbon brushes. This characteristic makes them ideal for use in sensitive electronic equipment or applications where electrical noise must be minimized.

Composite brushes are engineered using a combination of materials, such as carbon, graphite, and metal powders, to achieve specific performance characteristics. By tailoring the composition of the brush material, manufacturers can optimize properties such as electrical conductivity, mechanical strength, and wear resistance to suit particular motor applications.

For example, adding metal powders like copper or silver to the brush material can enhance electrical conductivity and improve current transfer efficiency. Incorporating lubricating agents or additives can help reduce friction and wear, extending brush life in high-speed or heavy-load applications.

Brushes serve several critical functions in DC motors, enabling these electrical machines to convert electrical energy into mechanical energy. The three primary functions of brushes in DC motors are current conduction, facilitating the commutation process, and enabling torque generation.

One of the most crucial tasks of brushes in DC motors is conducting electrical current from the external power source to the rotating armature windings. Brushes maintain continual contact with the commutator segments, allowing electrical current to flow into the armature coils. This direct contact enables the motor to draw the necessary current to generate the desired mechanical output.

As the armature rotates, the brushes make contact with different commutator segments, effectively reversing the polarity of the armature current.

This mechanical commutation process, facilitated by the interaction between brushes and the commutator, ensures that the armature experiences a consistent torque in the desired direction of rotation.

The interaction between brushes and the commutator in DC motors ultimately leads to torque generation, enabling the conversion of electrical energy into mechanical work. As the brushes conduct current into the armature windings, a magnetic field is generated around the armature. This field interacts with the permanent magnets in the stator, creating a torque that causes the armature to rotate.

The brushes are in constant contact with the rotating commutator. This physical and electrical contact allows the transfer of electrical current from the stationary brushes to the rotating armature windings.

The commutator consists of a series of copper segments arranged in a cylindrical shape and mounted on the motor shaft. Each segment is connected to a specific armature winding. As the commutator rotates with the armature, the brushes slide along the surface of the commutator, continuously switching the electrical connection between the input voltage source and the armature windings.

This process, known as commutation, ensures that the direction of the current flowing through the armature windings is periodically reversed. The reversal of current is necessary to maintain a continuous torque and enable the rotation of the motor. Without proper commutation, the motor would not be able to generate the required magnetic fields for operation.