Types of Centrifugal Blowers

Learn about the types of centrifugal blowers and their applications in various industries.

Read More

When selecting a fan for your industrial application, the choice between centrifugal and propeller fans can be confusing.

Making the wrong decision can lead to inefficient airflow, excessive noise, and wasted energy costs.

In this blog post, we will explore the distinct characteristics of centrifugal and propeller fans, and provide a detailed comparison of their performance in terms of airflow volume, pressure requirements, space limitations, noise levels, efficiency, and cost.

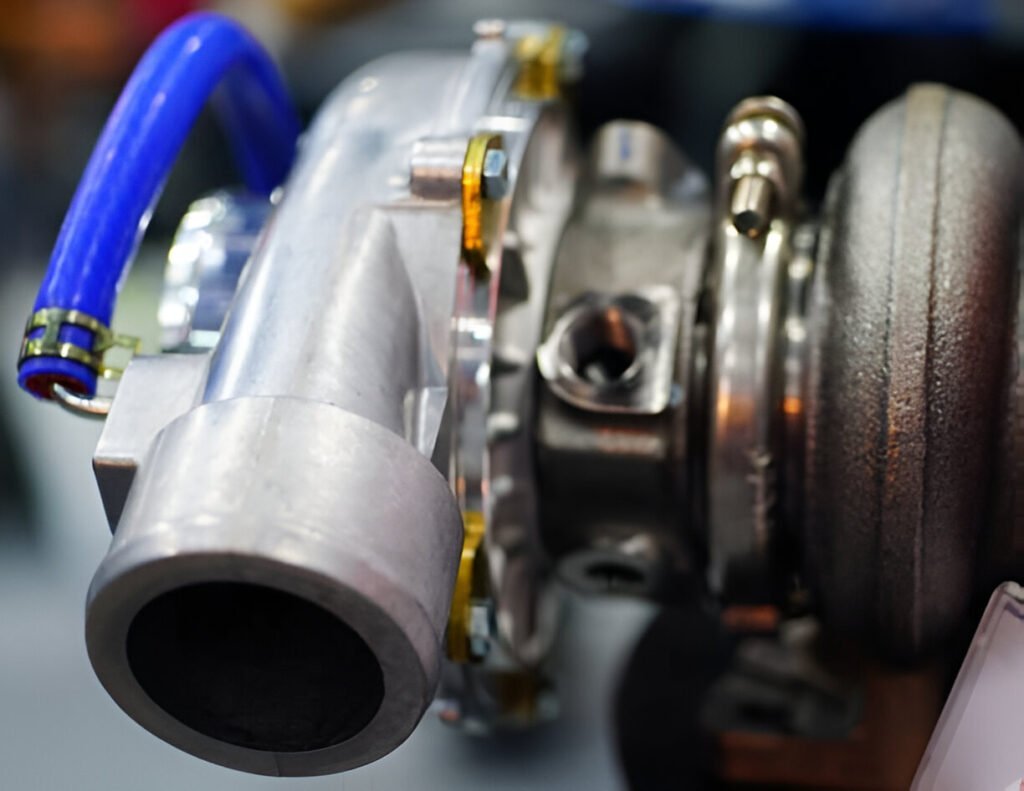

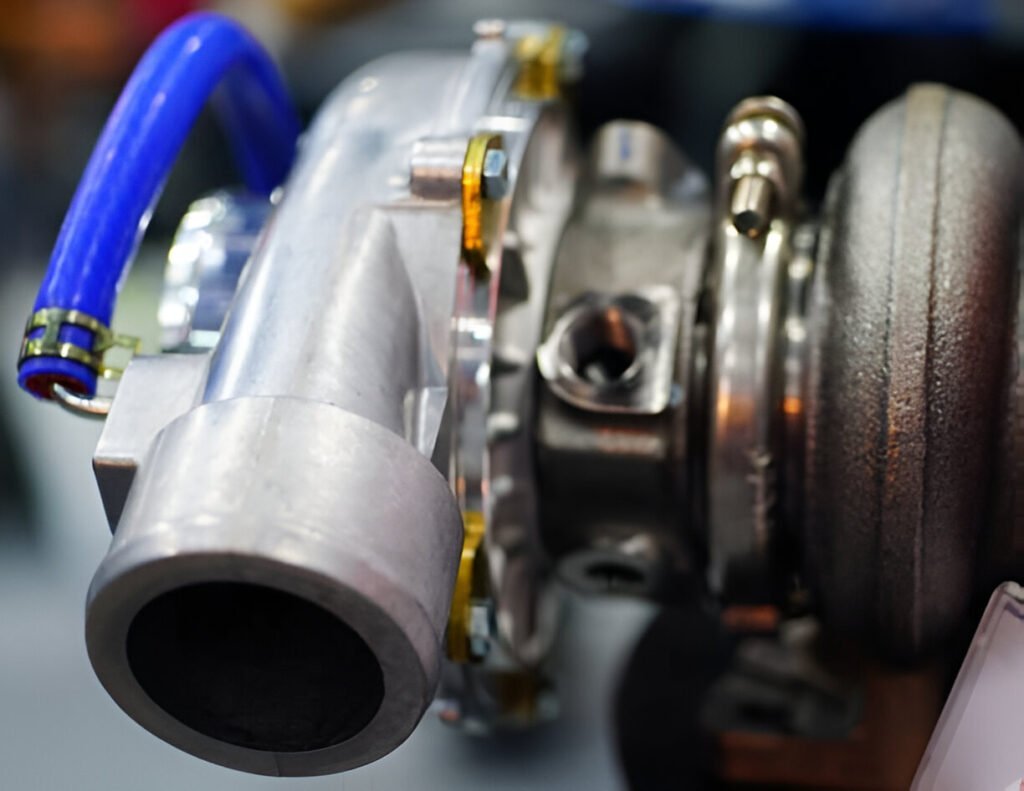

A centrifugal fan is a type of mechanical fan that uses centrifugal force generated by a rotating impeller to move air or other gases. The impeller is typically mounted on a shaft within a scroll-shaped housing. As the impeller rotates, it draws air into the center of the fan and accelerates it radially outward due to centrifugal force. The airflow is then directed through the housing and discharged perpendicularly to the incoming airflow.

A propeller fan, also known as an axial fan, is a type of fan that uses rotating blades to move air in a direction parallel to the shaft about which the blades rotate. The blades are typically mounted on a central hub and are designed to scoop air and propel it axially along the path of the blade rotation.

Propeller fans are designed to move large volumes of air at relatively low pressures. They are ideal for applications that require high airflow rates with minimal resistance.

Centrifugal fans are capable of moving moderate to high volumes of air, but their primary advantage lies in their ability to generate higher pressures.

Centrifugal fans are well-suited for applications that require overcoming resistance in the system, such as ductwork, filters, or heat exchangers. They can generate higher static pressures compared to propeller fans.

Propeller fans are more suitable for low-pressure applications where high airflow rates are needed with minimal resistance.

Centrifugal fans have a more compact design compared to propeller fans of similar airflow capacity. They can be installed in smaller spaces and are often used when space is limited.

Propeller fans, due to their axial design, require more space in the direction of airflow and are better suited for applications where space constraints are less stringent.

Propeller fans tend to be quieter than centrifugal fans, especially at lower speeds. The noise generated by propeller fans is primarily due to the airflow and blade rotation.

Centrifugal fans can produce higher noise levels due to the turbulence created by the air passing through the housing and the higher rotational speeds required to generate higher pressures.

Centrifugal fans generally have higher efficiencies when operating at their designed pressure and airflow rates. They are more suitable for systems with higher resistance and can maintain efficiency over a wider range of operating conditions.

Propeller fans, while efficient at moving large volumes of air at low pressures, may experience a drop in efficiency when faced with increased system resistance.

In general, propeller fans tend to be less expensive than centrifugal fans of similar airflow capacity.