What Happens When DC Motor Brushes Wear Out

Discover the consequences of worn-out brushes in DC motors, including reduced performance and potential damage.

Read More

Electric motors are the driving force behind countless machines and devices, from industrial equipment to household appliances. With their ability to convert electrical energy into mechanical energy, these versatile components play a crucial role in powering the modern world.

In this blog post, we will delve into the various types of electric motors, exploring their unique characteristics, applications, and advantages.

AC motors are a type of electric motor that convert alternating current electrical energy into mechanical energy.

Synchronous motors are a type of AC motor that operate at a constant speed, synchronized with the frequency of the supplied current. The rotor of a synchronous motor rotates at the same speed as the stator’s magnetic field, making them ideal for applications requiring precise speed control. Synchronous motors are classified into two main categories: excited and unexcited.

Excited synchronous motors have a rotor winding that is externally powered by a DC supply. This allows for greater control over the motor’s performance characteristics. The two primary types of excited synchronous motors are:

Single phase synchronous motors operate on a single-phase AC power supply. They are commonly used in small-scale applications, such as electric clocks, timers, and other devices requiring precise timing. These motors typically have a low power output and are not suitable for heavy-duty applications.

Three phase synchronous motors are powered by a three-phase AC supply and offer higher power output and efficiency compared to single-phase motors. They are used in large-scale industrial applications, such as compressors, pumps, and conveyor systems. Three-phase synchronous motors provide a constant speed output, even under varying load conditions.

Unexcited synchronous motors do not have an externally powered rotor winding. Instead, they rely on the interaction between the stator’s magnetic field and the rotor’s magnetic properties to generate torque. The two main types of unexcited synchronous motors are:

Reluctance motors have a rotor with salient poles made of ferromagnetic material. The rotor does not have any windings or permanent magnets. The motor’s torque is generated by the tendency of the rotor to align itself with the stator’s magnetic field, minimizing the reluctance of the magnetic circuit. Reluctance motors are known for their simple construction, high efficiency, and low cost.

Hysteresis motors have a rotor made of a special magnetic material that exhibits hysteresis properties. The rotor is magnetized by the stator’s rotating magnetic field, creating a magnetic flux that lags behind the stator field. This interaction generates a torque, causing the rotor to follow the stator field at synchronous speed. Hysteresis motors offer smooth, quiet operation and are often used in applications requiring constant speed, such as fans, blowers, and other small-scale devices.

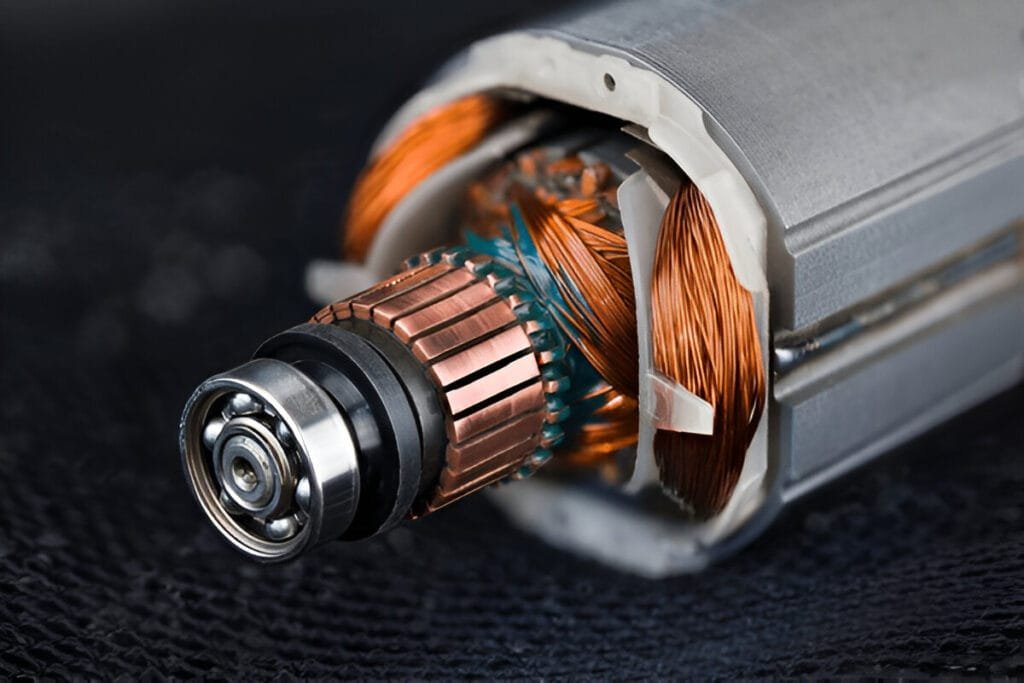

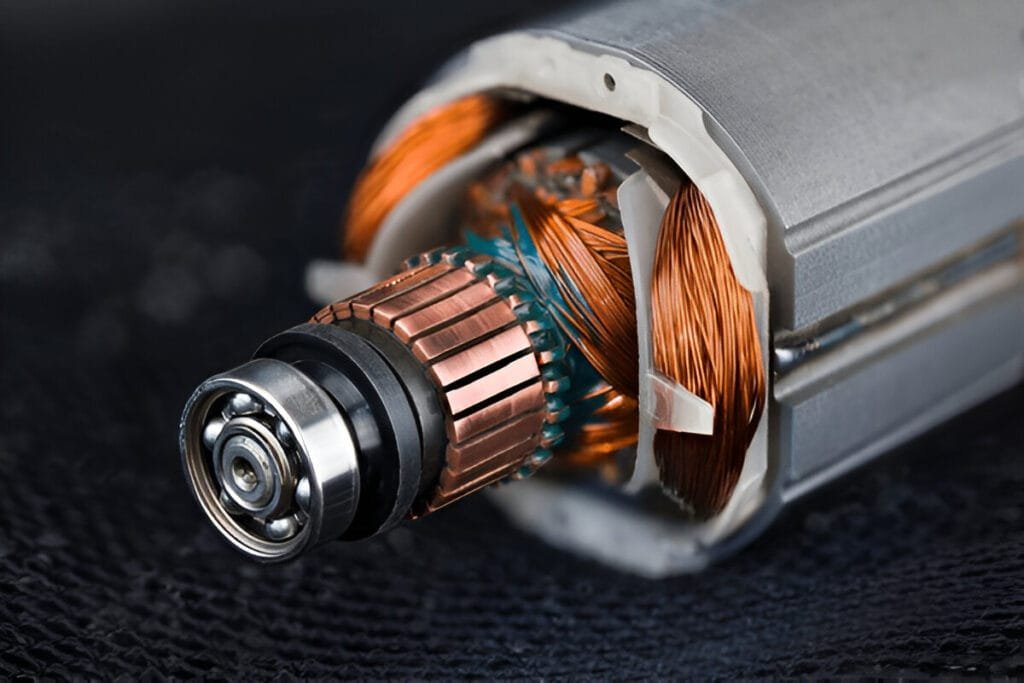

Induction motors, also known as asynchronous motors, are a type of AC motor that relies on electromagnetic induction to generate rotational motion. They are widely used in various applications due to their simple construction, rugged design, and low maintenance requirements. Induction motors consist of a stator winding that produces a rotating magnetic field and a rotor that is induced with currents, resulting in torque generation.

Squirrel cage induction motors are the most common type of induction motor. They feature a rotor constructed from a series of conductive bars arranged in a cylindrical shape, resembling a squirrel cage. When the stator windings are energized with a three-phase AC supply, a rotating magnetic field is created. This field induces currents in the rotor bars, generating a magnetic field that interacts with the stator field, causing the rotor to rotate. Squirrel cage induction motors are known for their simplicity, reliability, and low cost, making them suitable for a wide range of industrial applications, such as pumps, fans, and conveyor systems.

Slip ring or wound rotor induction motors have a rotor with windings connected to external resistors through slip rings and brushes. By adjusting the external resistance, the motor’s starting torque and speed can be controlled. This feature makes slip ring motors ideal for applications requiring high starting torque or variable speed control, such as cranes, hoists, and elevators. However, the presence of slip rings and brushes increases maintenance requirements compared to squirrel cage motors.

Capacitor start induction run motors are single-phase induction motors that employ a capacitor in the starting winding to create a phase shift, generating a rotating magnetic field. Once the motor reaches approximately 75% of its rated speed, a centrifugal switch disconnects the starting winding, and the motor continues to run on the main winding. These motors provide high starting torque and are commonly used in applications such as air conditioners, compressors, and pumps where single-phase power is available.

Capacitor start and capacitor run motors, also known as permanent split capacitor motors, use capacitors in both the starting and running windings. The capacitor in the starting winding provides high starting torque, while the capacitor in the running winding improves the motor’s power factor and efficiency. These motors offer smooth and quiet operation, making them suitable for applications requiring constant speed and low noise levels, such as fans, blowers, and machine tools.

DC motors, also known as direct current motors, are a type of electric motor that converts electrical energy into mechanical energy using direct current (DC) power.

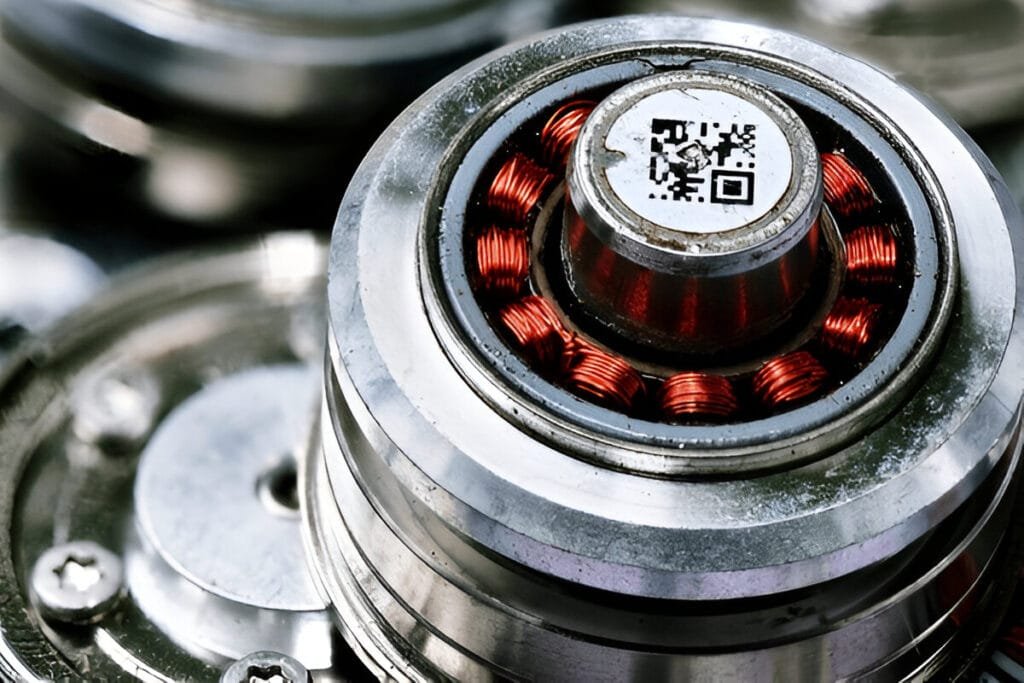

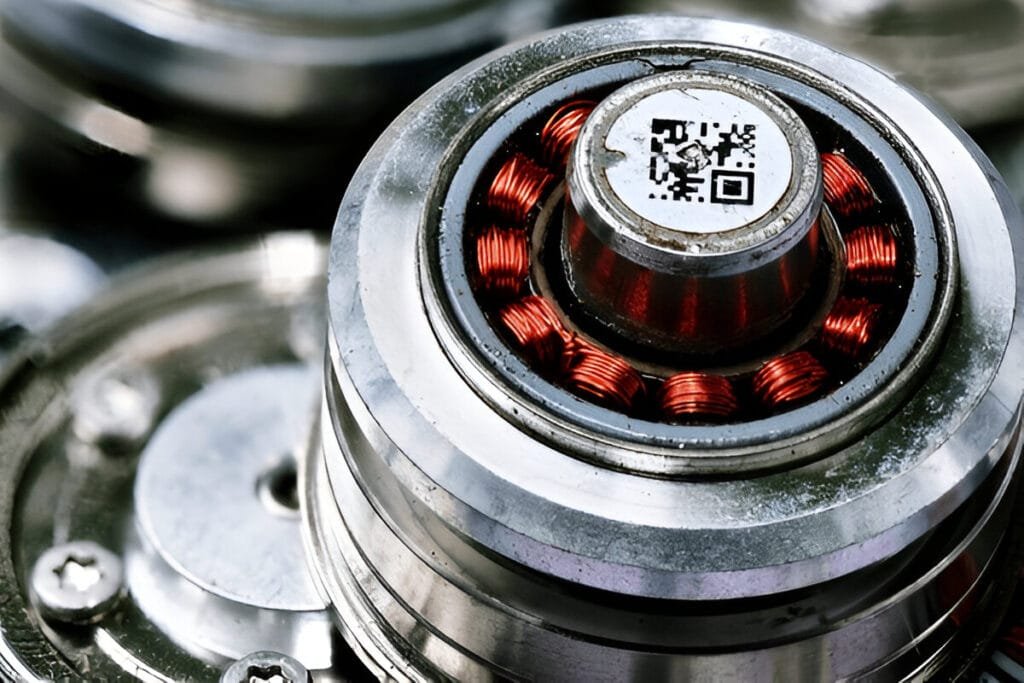

Brushed DC motors are the most common type of DC motor. They consist of a stator, which is the stationary part of the motor, and a rotor, which is the rotating part. The stator generates a magnetic field, while the rotor contains windings that carry the electrical current. The interaction between the magnetic field and the current in the rotor windings produces the torque that causes the motor to rotate.

Permanent Magnet DC (PMDC) motors use permanent magnets to create the stator’s magnetic field. This eliminates the need for field windings, making the motor more compact and efficient. PMDC motors are commonly used in applications that require high starting torque and precise speed control, such as robotics, automotive systems, and medical devices.

Self-excited DC motors generate their own magnetic field using the rotor windings. The field winding is connected in series or parallel with the armature winding, which carries the main current. There are three types of self-excited DC motors:

In a DC shunt motor, the field winding is connected in parallel with the armature winding. This configuration allows for good speed regulation and a wide range of speed control. Shunt motors are suitable for applications that require constant speed, such as conveyor systems and industrial machines.

In a DC series motor, the field winding is connected in series with the armature winding. This results in high starting torque, making series motors ideal for applications that require high torque at low speeds, such as electric vehicles and power tools. However, series motors have poor speed regulation and can reach dangerously high speeds if not loaded.

Compound wound DC motors combine the characteristics of both shunt and series motors. They have two field windings: one connected in series with the armature and the other in parallel. This configuration provides a balance between the high starting torque of series motors and the good speed regulation of shunt motors. Compound motors are used in applications that require both high starting torque and good speed regulation, such as elevators and printing presses.

In a separately excited DC motor, the field winding is powered by a separate DC source, independent of the armature winding. This allows for more precise control of the motor’s speed and torque, as the field current can be adjusted independently of the armature current. Separately excited motors are used in applications that require a wide range of speed control and high performance, such as machine tools and robotics.

A DC compound motor combines the characteristics of both series and shunt motors, featuring both series and shunt field windings. The shunt field winding is connected in parallel with the armature, while the series field winding is connected in series.

This configuration allows DC compound motors to exhibit good starting torque and speed regulation, making them suitable for applications requiring constant speed under varying loads, such as conveyors and printing presses. The series winding provides high starting torque, while the shunt winding helps maintain a relatively constant speed.

DC compound motors can be further classified as cumulative compound motors, where the series and shunt field windings aid each other, or differential compound motors, where the windings oppose each other.

Switched reluctance motors (SRMs) are a type of brushless DC motor that operate on the principle of magnetic reluctance. They consist of a stator with concentrated windings and a rotor with salient poles, neither of which contains permanent magnets. The stator windings are energized in a sequence, creating a magnetic field that attracts the nearest rotor pole, causing the rotor to align with the energized stator pole. By continuously switching the energized stator windings, the rotor is induced to rotate.

An electronic commutator, also known as an EC motor, is a brushless DC motor that uses electronic circuitry to perform commutation, replacing the traditional mechanical commutator and brushes. The electronic commutator consists of solid-state switches, such as transistors or MOSFETs, which are controlled by a microcontroller or dedicated IC. The microcontroller receives signals from position sensors, such as Hall effect sensors or encoders, to determine the rotor position and energize the appropriate stator windings.

Brushless DC motors, or BLDC motors, are synchronous motors powered by DC electricity. Unlike brushed DC motors, BLDC motors use electronic commutation to control the current in the stator windings, eliminating the need for physical commutators and brushes. The rotor contains permanent magnets, while the stator consists of windings. The electronic controller energizes the stator windings in a specific sequence, creating a rotating magnetic field that interacts with the permanent magnets on the rotor, causing it to rotate.

Specialty motors are a diverse group of electric motors designed for specific applications and requirements. These motors offer unique features and capabilities that set them apart from standard AC and DC motors.

Stepper motors are a type of brushless DC motor that provides precise position control and high holding torque. They are commonly used in applications requiring accurate positioning, such as 3D printers, CNC machines, and robotics. Stepper motors divide a full rotation into a large number of discrete steps, allowing for precise incremental movements. By sending controlled pulses to the motor windings, the motor shaft can be rotated in precise increments, enabling accurate positioning without the need for a closed-loop feedback system.

Stepper motors typically have multiple field windings that are energized in a specific sequence to create a rotating magnetic field. The rotor, which contains permanent magnets or a toothed iron core, follows the rotating magnetic field, resulting in precise stepwise motion.

There are three main types of stepper motors: permanent magnet, variable reluctance, and hybrid.

Servo motors are another type of specialty motor known for their precise position control and high torque output. They are commonly used in applications that require accurate positioning, fast response times, and smooth motion control, such as robotics, automation systems, and aerospace applications.

A servo motor consists of a motor coupled with a position feedback device, such as an encoder or resolver. The feedback device measures the actual position of the motor shaft and sends this information to a servo controller. The controller compares the actual position with the desired position and adjusts the motor’s power supply accordingly to minimize the error. This closed-loop control system allows servo motors to achieve high levels of precision and responsiveness.

Linear motors are a type of electric motor that produces linear motion instead of rotational motion. They are used in applications that require precise linear positioning, high speeds, and long travel distances, such as machine tools, transportation systems, and semiconductor manufacturing equipment.

A linear motor consists of a stationary track (stator) and a moving part (rotor or forcer) that contains permanent magnets or windings. The stator contains a series of coils that, when energized, create a traveling magnetic field. The interaction between the moving magnetic field and the permanent magnets or windings on the rotor produces a linear force, causing the rotor to move along the track.

Direct drive motors, also known as torque motors, are designed to provide high torque output without the need for a gearbox or other mechanical transmission components. They are commonly used in applications that require high precision, fast response times, and smooth motion control, such as robotics, aerospace systems, and medical devices.

In a direct drive motor, the load is directly coupled to the motor shaft, eliminating the need for intermediate gearing. This direct coupling allows for high mechanical stiffness, reduced backlash, and improved positioning accuracy. Direct drive motors typically have a large diameter and short axial length to maximize torque output while minimizing inertia.

Universal motors, also known as series wound motors, are a type of electric motor that can operate on either AC or DC power. They are commonly used in portable power tools, household appliances, and other applications that require high starting torque and variable speed control.

In a universal motor, the field windings and armature windings are connected in series. This series connection gives the motor its unique characteristics, such as high starting torque and the ability to operate on both AC and DC power. When AC power is applied, the direction of current in both the field and armature windings reverses simultaneously, maintaining a unidirectional torque.