The 880 series overloaded vector inverter is a cutting-edge device designed to optimize motor control and enhance operational efficiency. It features flexible control and intuitive LED display for easy operation and adjustment. With a smart chip and stable performance, it ensures reliability under various conditions. The inverter is multifunctional, offering speed regulation and constant pressure water supply control, making it suitable for a wide range of industrial applications.

Application environment

The 880 series overloaded vector inverter is designed to excel in diverse and demanding industrial environments. It is well-suited for applications requiring precise motor speed control, such as in manufacturing plants and machinery. The inverter ensures stable operation in conditions with varying loads, providing energy savings and enhanced production efficiency. Its robust design guarantees reliable performance even in challenging settings.

Product parameters

| Frequency Converter Model | Matching Motor | Rated Output Current (A) | Outside Reference Number | |

| KW | HP | |||

| 880-0007M1 | 0.75 | 1 | 4 | 01 |

| 880-0015M1 | 1.5 | 2 | 7 | 01 |

| 880-0022M1 | 2.2 | 3 | 10 | 01 |

| 880-0007M3 | 0.75 | 1 | 2.5 | 01 |

| 880-0015M3 | 1.5 | 2 | 3.7 | 01 |

| 880-0022M3 | 2.2 | 3 | 5.1 | 01 |

| 880-0040M3 | 4 | 5 | 8.5 | 02 |

| 880-0055M3 | 5.5 | 7.5 | 13 | 03 |

| 880-0075M3 | 7.5 | 10 | 16 | 04 |

| 880-0110M3 | 11 | 15 | 25 | 05 |

| 880-0150M3 | 15 | 20 | 32 | 06 |

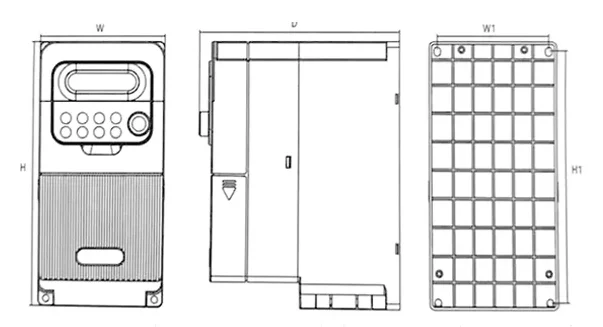

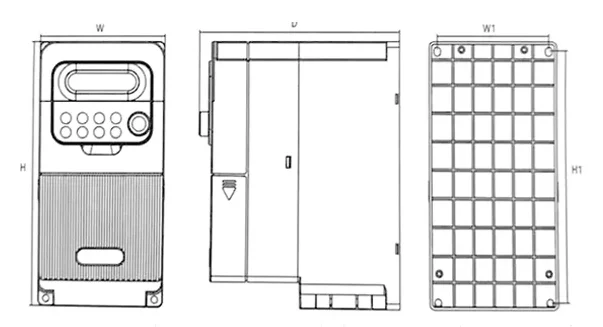

| Reference Number | Power | Dimensions (mm) | Installation | Hole Diameter φ | |||

| H | W | D | H1 | W1 | |||

| 01 | 0.75~1.5KW/220V 0.75~2.2KW/380V | 152.99 | 86 | 124.9 | 145 | 76 | 4.5mm |

| 02 | 2.2KW/220V 4KW/380V | 170 | 86 | 130.0 | 159 | 76 | 5mm |

| 03 | 5.5KW/380V | 188 | 96 | 152.3 | 176.5 | 83.6 | 5mm |

| 04 | 7.5KW | 201 | 106 | 169.7 | 190.0 | 93 | 5mm |

| 05 | 11KW | 228 | 114 | 187.2 | 214.5 | 98.7 | 5mm |

| 06 | 15KW | 290 | 160 | 181.3 | 270 | 143 | 6.5mm |

| *Product upgrade, size update without prior notice. | |||||||

Dimension

Product Features

- The 880 series overloaded vector inverter offers flexible control capabilities, allowing for precise and adaptable adjustments to various equipment. This feature ensures optimal performance and ease of use, making it suitable for a wide range of industrial applications.

- With its intuitive LED display, the 880 series inverter provides a user-friendly interface. The large display screen enhances readability and operational efficiency, enabling users to monitor and adjust settings effortlessly.

- Equipped with a smart chip, this inverter guarantees stable and reliable performance. The thickened three-proof coating design ensures moisture-proof and anti-static properties, protecting the frequency conversion core motherboard and enhancing durability.

- The multifunctional design of the 880 series inverter integrates several features into one compact unit. It includes an EPCOS electrolytic capacitor for stable charging and discharging, composite flame-retardant plastic for safety, and a built-in cooling fan to maintain optimal operating temperatures.

- This inverter boasts a wide scope of application, capable of achieving motor speed regulation, energy saving, and emission reduction. It enhances production efficiency and is ideal for various motor control scenarios, including constant pressure water supply systems.

- The 880 series overloaded vector inverter is designed for convenience and efficiency. It offers multiple functions such as multi-mode regulation, energy and power saving, and protective motor features. With a 1-year warranty, it ensures reliable and hassle-free operation.

Product installation and instructions

- First, select a stable and well – ventilated installation location to ensure proper heat dissipation for the 880 series over – load vector inverter.

- Fix the inverter firmly on the mounting surface using suitable screws and mounting brackets to prevent vibration and displacement.

- Connect the power cables correctly according to the marked terminals on the inverter, ensuring a secure and reliable power supply connection.

- Link the motor cables to the corresponding output terminals of the inverter, making sure the connections are tight to avoid poor contact.

- Finally, check all connections once more, and then power on the inverter for initial testing and commissioning to ensure normal operation.

Note:For the 880 series over-load vector inverter, ensure installation in a well-ventilated area. Avoid over-tightening cables during connection. Regularly inspect for dust accumulation and clean gently. Never disassemble it without professional guidance.

Product images

Request a Quote Now

Our team will get back to you within 24 hours.