Fan overview

The explosion-proof performance of explosion-proof pneumatic axial fans (hereinafter referred to as pneumatic fans) complies with the provisions of “General Requirements for Explosion proof Electrical Equipment for Explosive Environments” and “Explosion proof Electrical Devices for Explosive Spaces”. This regulation is for explosion-proof type

The explosion-proof mark is d IIBT, which is suitable for Class 1, A, B, T1, T2, T3, T4, temperature group, explosive environment formed by combustible gas and air.

Use

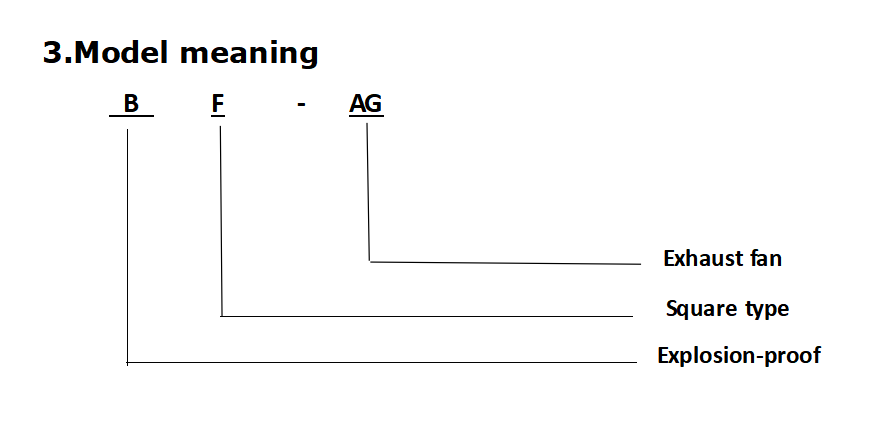

Model meaning

Parameter

| Model | Biade diameter (mm) | Consumption of gas(m³/h) | Air volume (m³/h) | Air pressure used (mpa) | Rotating speed (r/min) | Wind pressure (pa) | Tracheal diameter |

| BFAG(BSTQ)-II-30 | 300(12inch) | 1.0 | 3900 | 0.6 | 3000 | 260 | φ10 |

| BFAG(BSTQ)-II-35 | 350(14inch) | 1.0 | 4500 | 0.6 | 2600 | 220 | φ10 |

| BFAG(BSTQ)-II-40 | 400(16inch) | 2.2 | 6300 | 0.6 | 2200 | 300 | φ16 |

| BFAG(BSTQ)-II-45 | 450(18inch) | 2.2 | 7100 | 0.6 | 1800 | 220 | φ16 |

| BFAG(BSTQ)-II-50 | 500(20inch) | 2.2 | 9000 | 0.6 | 1500 | 200 | φ16 |

| BFAG(BSTQ)-II-60 | 600(24inch) | 2.2 | 14700 | 0.6 | 1300 | 190 | φ16 |

| BFAG(BSTQ)-II-70 | 700(28inch) | 2.2 | 17700 | 0.6 | 1200 | 180 | φ16 |

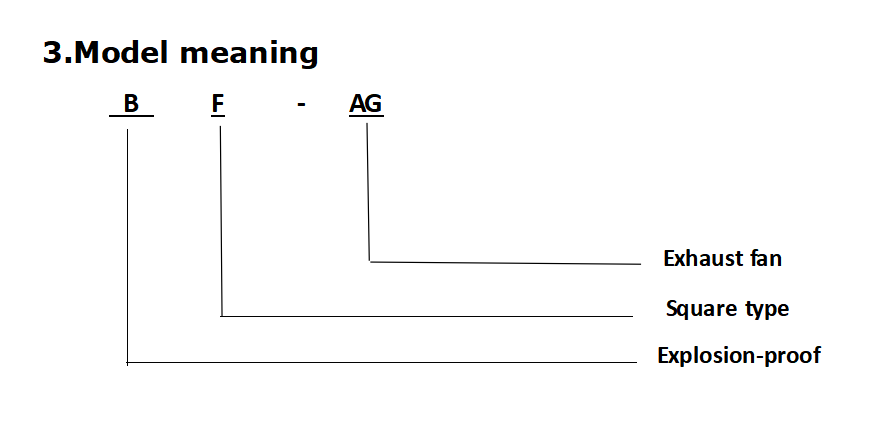

Dimension

Installation

- First check whether the frame and fan blades are deformed, whether the fan blades rotate flexibly, and whether there is friction. Check whether all fasteners are complete, tightened, and have explosion-proof certificate numbers.

- The line voltage must match the rated voltage on the motor.

- Check the insulation resistance of the motor with a 500V megohmmeter. If its resistance value is less than 5MQ, use drying method or short-circuit current method for drying treatment to make the insulation resistance greater than 5MQ.

- A small explosion-proof switch must be used as the power switch, or the flexible switch must be installed in an outdoor place where there is no risk of explosion.

- The outer diameter of the cable connected to the power supply should be consistent with the sealing ring. After tightening and pressing the nut, ensure that there is no gap between the sealing ring and the cable, and between the sealing ring and the outlet nozzle, otherwise the explosion-proof performance will be lost.

- When assembling, ensure that the explosion-proof clearance is less than 0.2mm. Replace the grease of the motor bearing. The grease brand is ZG-2H compound calcium-based lubricant.

- The non-wiring part of the explosion-proof motor cannot be disassembled at will. When wiring, open the cover of the wiring room, insert the lead wire and connect it to the terminal. After connection, cover and tighten the screw to make the explosion-proof surface clearance less than 0.2mm, and then tighten it. The lead wire can’t move.

Note:When installing, pay attention to the explosion-proof surface. When assembling, the explosion-proof surface must be coated with 204-1 anti-rust grease. All explosion-proof surfaces must not be damaged or rusted, otherwise the explosion-proof performance will be lost. If there is damage or rust, it shall be repaired in accordance with the “Provisions for the Treatment of Explosion-Proof Surface Defects of Explosion-proof Electrical Equipment”.

- The exhaust fan in use should be frequently cleaned of dust and other accumulations on the motor to avoid affecting heat dissipation.

- When the exhaust fan that has not been used for a long time is re-used, it should be checked again according to the instructions, and it can be used only after being qualified.

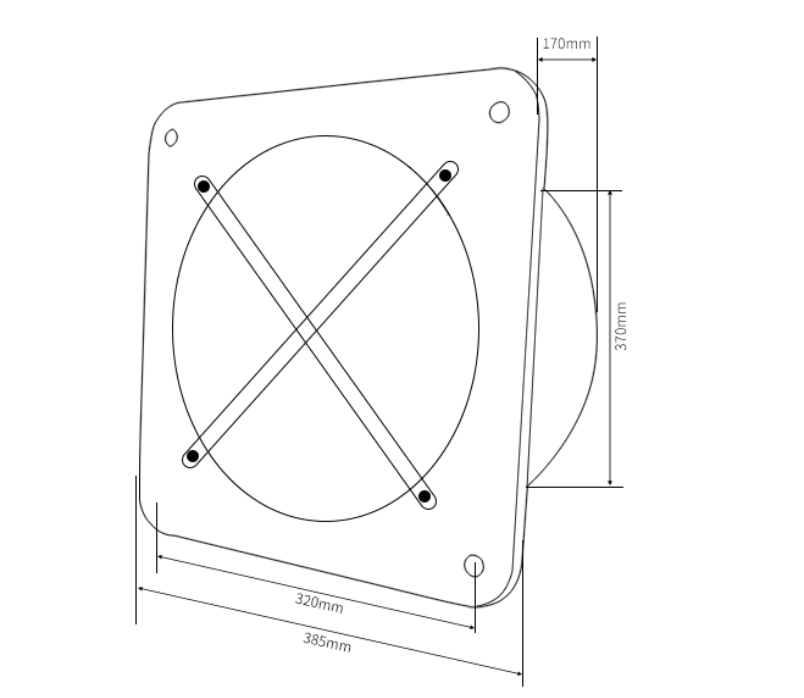

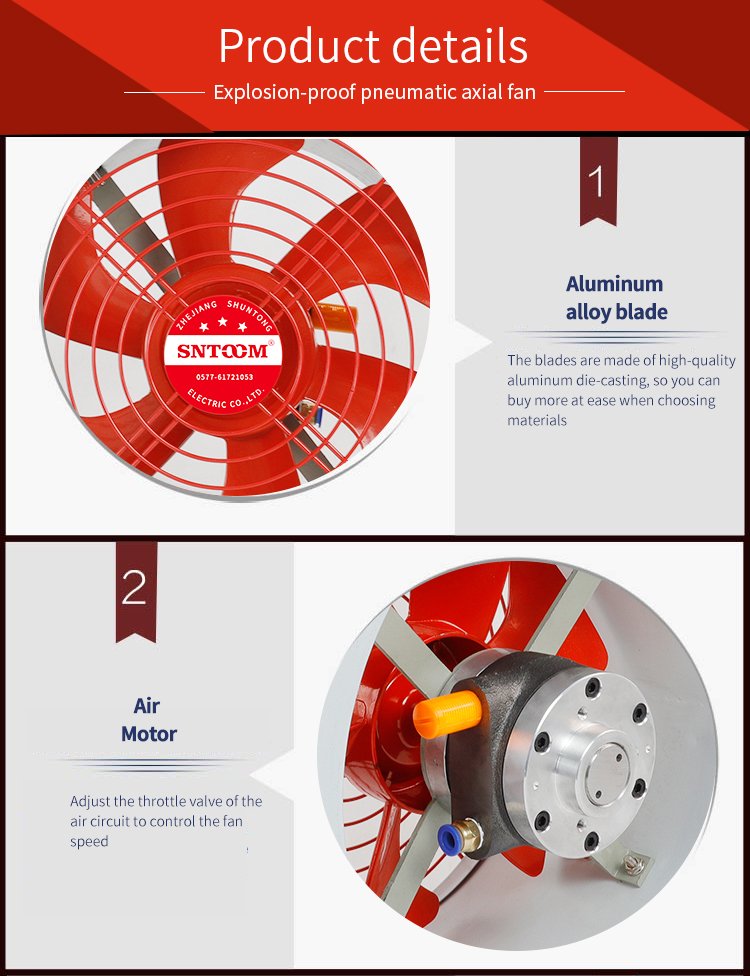

Product images

Request a Quote Now

Our team will get back to you within 24 hours.