Product Introduction

The GMC series AC contactor is a high-performance, multifunctional device designed for reliable electrical control. Featuring a flame-retardant housing and pure copper coil, it ensures stable voltage and enhanced safety. With easy guide rail installation, smart chip protection, and multifunctional capabilities including auto-reset and indicator lights, it offers durability, ease of use, and comprehensive protection for diverse industrial applications.

Application range

- VMC series AC contactor is sutable for using in the circuits up to the rated voltage 660V AC 50/60Hz, rated current up to 85A for making breaking frequently starting & contolling the AC motor.

- Combined with the auxiliary contact block, timer delay & machine-interlocking device etc, it becomes the delay contactor, mechanical interlocking contactor, star-delta starter.

- With the themal relay, it is combined into the electromagnetic starter.

- It conforms to IEC60947-1 standard.

Product parameters

| Type | VGMC-9 | VGMC-12 | VGMC-18 | VGMC-22 | VGMC-32 | VGMC-40 | VGMC-50 | VGMC-65 | VGMC-75 | VGMC-85 | ||

| AC1 duty | 20A | 20A | 25A | 32A | 50A | 60A | 80A | 100A | 110A | 135A | ||

| AC3 duty | 200~240V | 2.5kW11A | 3.5kW13A | 4.5kW18A | 5.5kW22A | 7.5kW32A | 11kW40A | 15kW55A | 18.5kW65A | 22kW75A | 25kW85A | |

| 380~440V | 4kW9A | 5.5kW12A | 7.5kW18A | 11kW22A | 15kW32A | 18.5kW40A | 22kW50A | 30kW65A | 37kW75A | 45kW85A | ||

| 500~550V | 4kW7A | 7.5kW12A | 7.5kW13A | 15kW22A | 18.5kW28A | 22kW32A | 30kW43A | 37kW60A | 45kW64A | 45kW75A | ||

| 690V | 4kW5A | 7.5kW9A | 7.5kW9A | 15kW18A | 18.5kW21A | 22kW25A | 30kW33A | 37kW47A | 45kW47A | 45kW52A | ||

| Continuous current(Ith) | 20A | 25A | 30A | 32A | 45A | 50A | 70A | 80A | 90A | 100A | ||

| AC motor | Single phase | 115V | 0.5HP | 0.5HP | 1HP | 2HP | 2HP | 3HP | 3HP | 5HP | 5HP | 7.5HP |

| 230V | 1HP | 2HP | 3HP | 3HP | 5HP | 5HP | 7.5HP | 10HP | 15HP | 15HP | ||

| Three phase | 200V | 2HP | 3HP | 5HP | 7HP | 7.5HP | 10HP | 10HP | 15HP | 20HP | 25HP | |

| 230V | 3HP | 3HP | 5HP | 7.5HP | 10HP | 10HP | 15HP | 20HP | 25HP | 30HP | ||

| 460V | 2HP | 7.5HP | 10HP | 10HP | 20HP | 25HP | 30HP | 40HP | 50HP | 50HP | ||

| 575V | 5HP | 10HP | 15HP | 15HP | 20HP | 25HP | 30HP | 40HP | 50HP | 50HP | ||

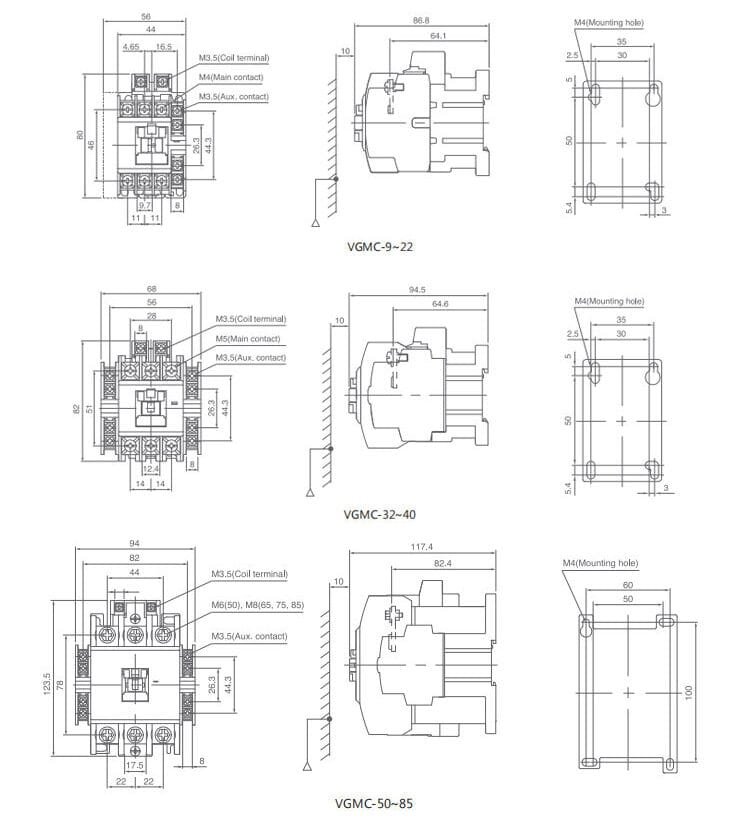

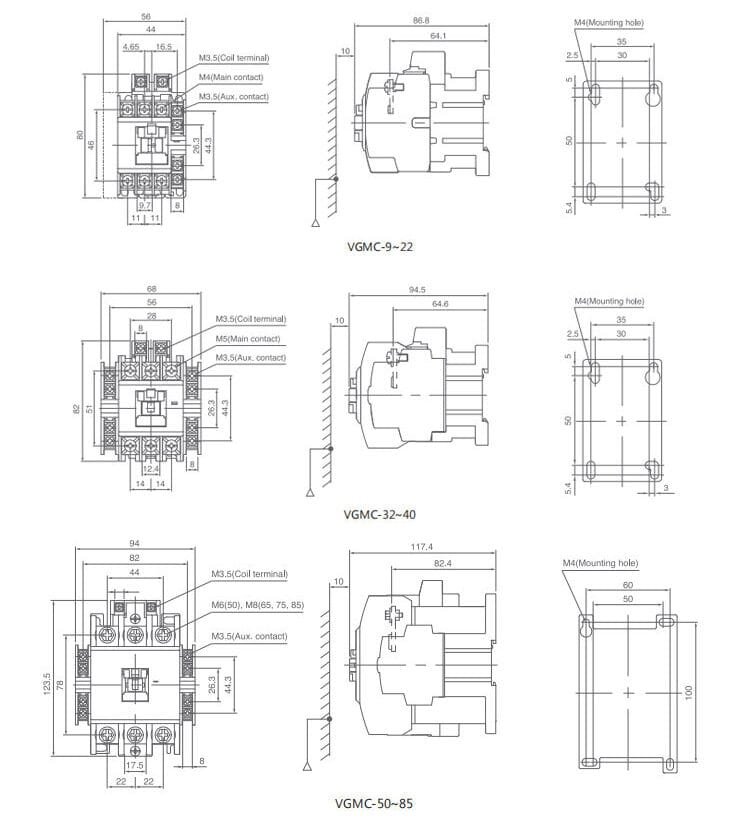

Outline and mounting dimension

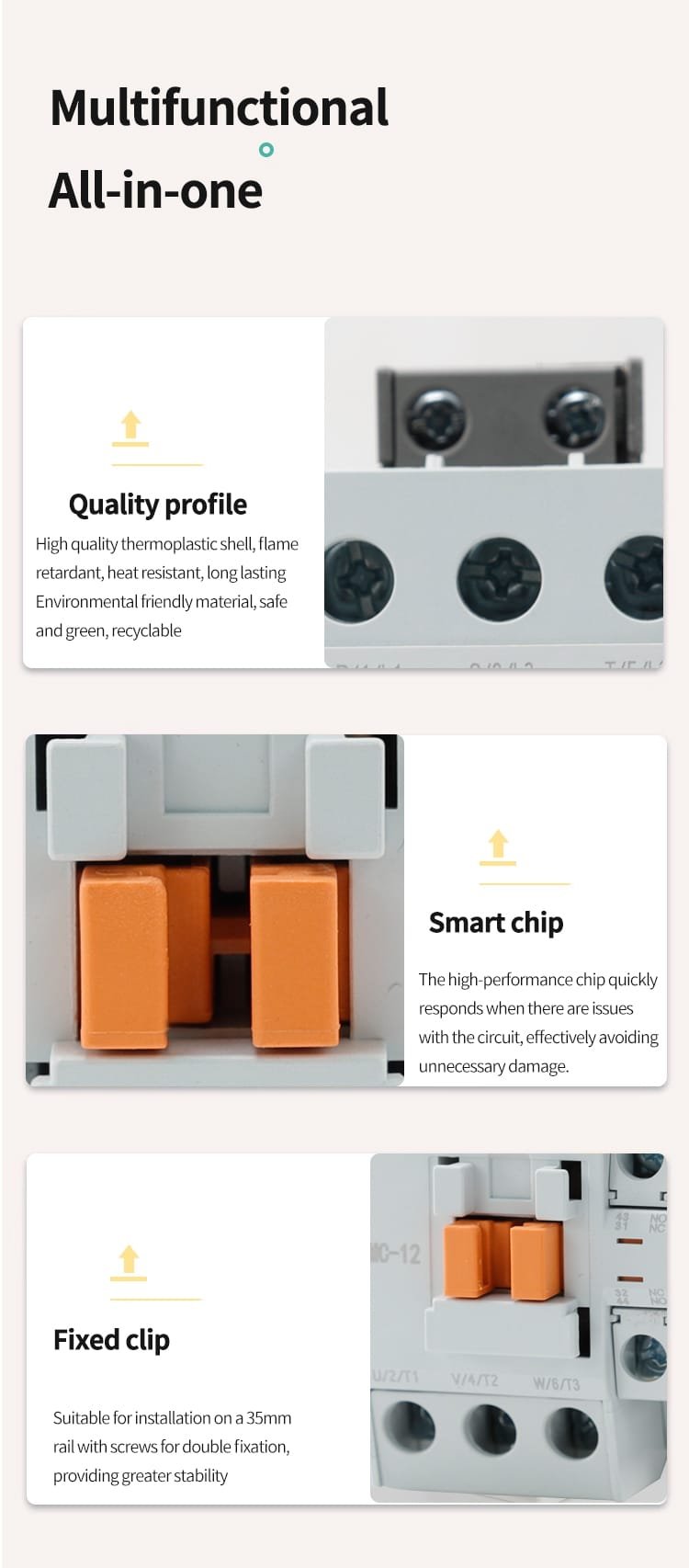

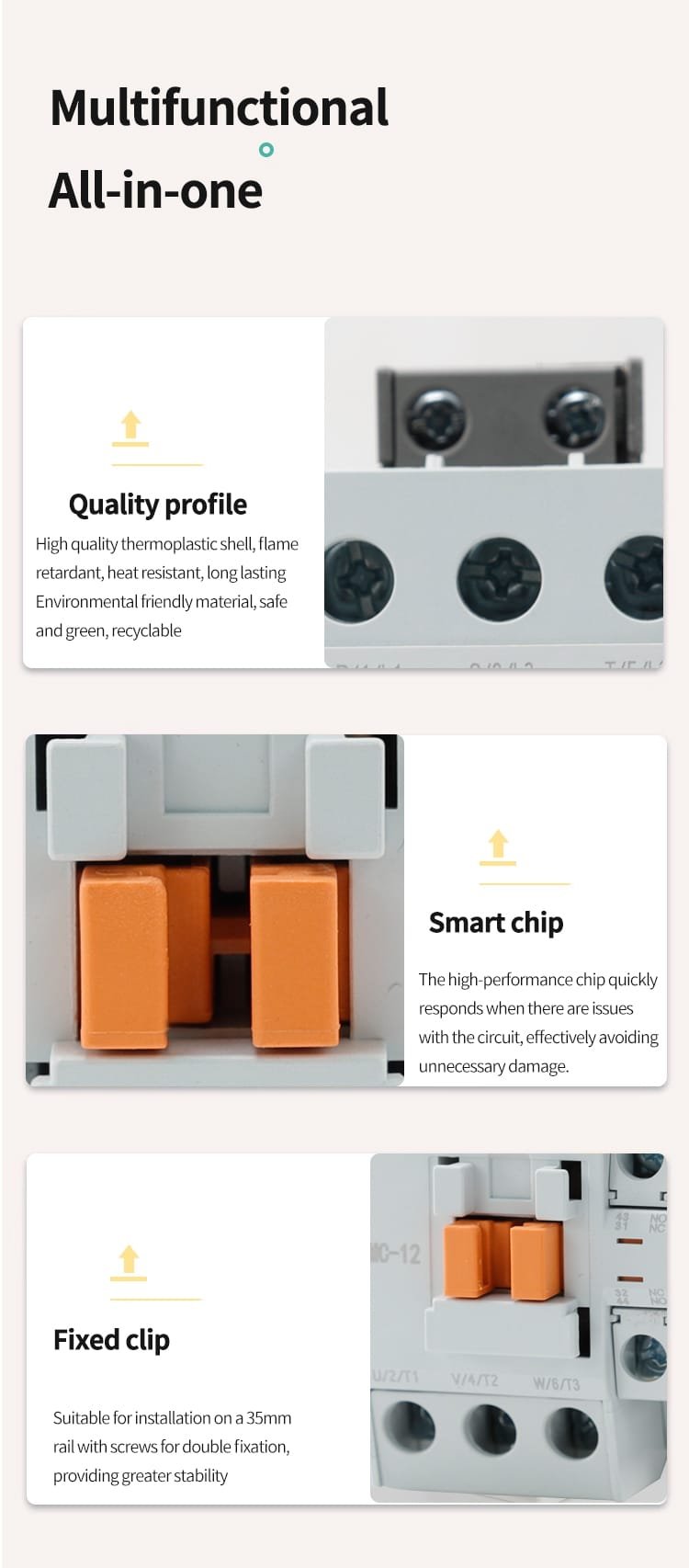

Product Features

The GMC series AC contactor features a flame-retardant housing, ensuring enhanced safety by resisting high temperatures and corrosion. Its hard fireproof material shell provides reliable protection, making it ideal for demanding industrial environments where safety is paramount.

Designed for ease of installation, the GMC series AC contactor includes a guide rail snap-in feature, allowing for quick setup on 35MM standard tracks. This design not only simplifies installation but also contributes to a longer service life, reducing maintenance costs.

The GMC series AC contactor is multifunctional, integrating quality features such as a high-quality thermoplastic shell that is flame-retardant, heat-resistant, and environmentally friendly. Its smart chip ensures rapid response to circuit issues, preventing unnecessary damage and enhancing reliability.

Engineered for communication applications, the GMC series AC contactor guarantees instant delivery, quality assurance, and stable performance. Its fixed clip design allows for secure installation on 35mm rails with screws, providing greater stability and ensuring consistent operation in critical systems.

The GMC series AC contactor utilizes a pure copper coil, ensuring stable voltage, fully automatic winding, and low heat generation. This design not only enhances efficiency but also prolongs the lifespan of the contactor, making it a cost-effective solution for various industrial applications.

Note:If any abnormality is found, immediately stop the power supply for inspection and adjustment. After ensuring that everything is normal, the contactor can be put into formal use.

Product installation and instructions

- Preparation:Check the contactor’s appearance, labels, and accessories. Prepare necessary tools like screwdrivers and wrenches.

- Choose Installation Site:Select a well-ventilated, dry, vibration-free spot with ample space. Ensure the mounting surface is flat and sturdy.

- Install Contactor:Align with a 35mm guide rail and snap in, or secure with screws on the mounting base, avoiding over-tightening.

- Wire Connection:Identify main and control circuit terminals. Connect power and load wires to main terminals, and control wires as per the circuit diagram, ensuring correct sequence and polarity.

- Inspection and Testing:Verify all wiring for correctness and security. Power on to test normal operation, observing main contact switching and auxiliary contact signals.

- Final Check:Monitor for abnormal noise or overheating during test runs. Adjust if necessary before formal use.

Product images

Request a Quote Now

Our team will get back to you within 24 hours.