Axial Fans Vs EC Fans: What Is the Differences

Axial fans and EC fans differ in design and efficiency. EC fans offer better performance, energy savings, and control.

Read More

Axial fan and propeller fans differ in design, performance, and applications. Axial fans excel in high-pressure situations, creating focused airflow with better efficiency and lower noise levels, ideal for HVAC systems and electronics cooling. Propeller fans are best for low-pressure applications, moving large volumes of air in open spaces like warehouses and factories, offering simpler and more affordable solutions but with higher noise levels.

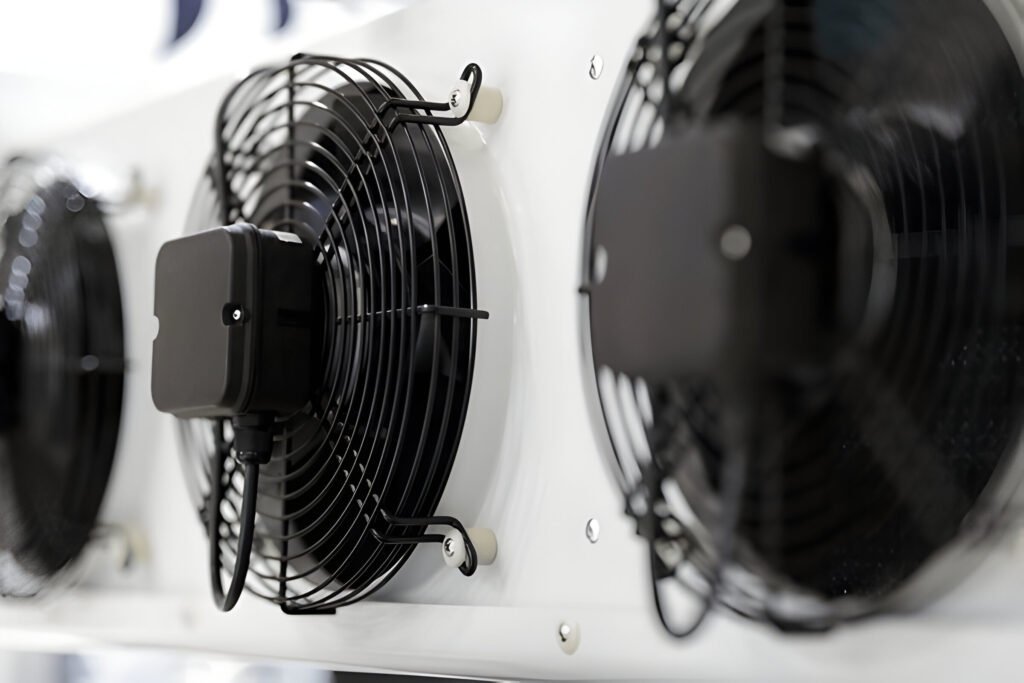

Axial fans move air parallel to their rotation axis. They consist of a hub with attached blades rotating in a cylindrical housing. This design creates a pressure difference, forcing air through the fan.

These fans excel at moving large air volumes efficiently, making them suitable for high airflow applications. Common uses include computer cooling and industrial ventilation.

Two main configurations exist: tube axial and vane axial. Tube axial fans feature only the fan and housing, while vane axial fans incorporate guide vanes for improved airflow and efficiency.

Axial fans excel in applications requiring high airflow rates and low to medium pressure. They move large volumes of air efficiently, making them ideal for ventilation systems in commercial and industrial settings.

Compact design is a key advantage of axial fans. They occupy less space compared to other fan types, facilitating installation in confined areas.

Energy efficiency is a notable feature of axial fans. They consume less power relative to the airflow produced, reducing operating costs. Maintenance is simpler due to fewer moving parts, which decreases wear over time.

Axial fans handle high temperatures effectively, making them suitable for demanding environments like industrial processes or data centers. When properly installed and maintained, they operate at relatively low noise levels.

Axial fans serve diverse cooling and ventilation purposes across industries. HVAC systems employ these fans to circulate air in large buildings, warehouses, and factories, maintaining air quality and temperature control.

Electronics industry relies on axial fans for cooling computer components, servers, and heat-generating equipment. Their compact size allows integration into desktop computers and laptops, efficiently dissipating heat.

Automotive applications utilize axial fans in radiator cooling systems and engine compartments to prevent overheating. Power plants incorporate these fans in cooling towers and boiler systems.

Mining and tunneling industries use axial fans for underground ventilation, removing harmful gases and dust while supplying fresh air to workers.

Agriculture implements axial fans in greenhouses and livestock buildings to maintain optimal growing conditions and animal comfort. Aerospace and automotive industries employ them in wind tunnels for aerodynamic testing.

Offer industrial Booster Fan customization services and free technical guidance. Contact us immediately to help you enhance the ventilation efficiency of your factory!

Propeller fans, or prop fans, are axial fans that move large air volumes at low pressures. Their large, propeller-like blades rotate around a central hub. These fans serve industrial and commercial applications requiring significant air circulation.

Prop fans generate high airflow rates with minimal energy consumption. They excel in open areas with little airflow resistance.

Propeller fans excel at moving large air volumes but are not suitable for high-pressure or precise air control applications. They perform best for general ventilation and cooling in spacious environments with free air flow.

Propeller fans excel in moving large air volumes with minimal resistance, making them ideal for ventilation in open spaces like warehouses, factories, and agricultural settings.

Simplicity is a key advantage of propeller fans. They have fewer components than other fan types, resulting in lower costs and easier maintenance. This design also enhances reliability due to fewer parts that can fail or wear out.

Energy efficiency is another benefit of propeller fans, especially when moving air over long distances. They consume less power relative to the air volume moved, leading to energy savings in large-scale applications.

Propeller fans produce strong, directional airflow, making them effective for spot cooling or ventilation in specific areas requiring targeted air movement.

Propeller fans excel in ventilating large spaces. Industrial settings like factories, warehouses, and manufacturing plants utilize these fans to move large air volumes quickly, maintaining air quality and temperature control in spacious environments.

Agricultural applications include livestock barns and greenhouses. Propeller fans regulate temperature, remove excess moisture, and ensure proper air circulation for animals and plants. Parking garages employ these fans to expel exhaust fumes and maintain air quality.

Cooling towers for industrial processes and HVAC systems often incorporate propeller fans. They effectively dissipate heat and promote evaporation. The marine industry uses propeller fans in engine rooms and below-deck areas of ships for vital ventilation.

Commercial kitchen exhaust systems feature propeller fans to remove heat, smoke, and cooking odors. Tunnels and mines also use these fans to ensure proper air circulation and remove potentially harmful gases.

Axial fans and propeller fans differ in airflow direction. Axial fans move air parallel to the shaft, creating a focused, straight airflow. They pull air in from one side and push it out the other.

Propeller fans disperse air in a radial pattern. While they move air along the rotation axis, the airflow is less concentrated than axial fans.

Axial fans operate under high pressure conditions and overcome system resistance effectively. They generate focused airflow, maintaining performance in moderate to high static pressure environments.

Propeller fans suit low-pressure applications but struggle with significant system resistance. They perform optimally in open spaces or situations with minimal airflow obstructions.

Axial fans produce less noise than propeller fans due to their design and operational characteristics. Axial fans operate at lower speeds and have more blades, distributing workload and reducing blade stress. Guide vanes in axial fans direct airflow efficiently, minimizing turbulence and associated noise.

Propeller fans generate higher noise levels. They operate at higher speeds with fewer blades, increasing blade stress and turbulence. The absence of guide vanes in propeller fans results in chaotic airflow, contributing to increased noise production.

Axial fans excel in efficiency, particularly at higher pressures. Their design incorporates multiple blades and guide vanes, directing airflow effectively. This configuration converts more input power into air movement, enhancing overall energy efficiency.

Propeller fans offer lower efficiency than axial fans. Their simpler design, with fewer blades and no guide vanes, limits performance in high-pressure situations. However, they remain efficient in low-pressure applications like open space ventilation.

Axial fans cost more than propeller fans due to their complex design and advanced engineering. Axial fans require precision manufacturing, high-quality materials, and sophisticated blade designs, contributing to their higher initial price.

Axial fans, despite higher upfront prices, often prove more cost-effective over time due to superior efficiency and durability. They consume less energy and require less maintenance.

Axial and propeller fans are not universally interchangeable.

Axial fans and propeller fans are similar and often terms are used interchangeably. Propeller fans have long, narrow blades and push air in a straight line, mainly for low resistance airflow. Axial fans have shorter, wider blades in a housing and are designed to move air with slightly higher pressure, suitable for duct systems with some resistance.

Propeller fans are ideal for general ventilation in open spaces where high airflow is needed but resistance is low. Axial fans are used in industrial and commercial ventilation, HVAC systems, and cooling towers where airflow must overcome duct resistance.

Yes, axial fans are sometimes referred to as propeller fans because the blade shape resembles an aircraft propeller and they move air axially along the shaft.