Axial Fans Vs Centrifugal Fans: What’s the Difference

Axial fans move air linearly, while centrifugal fans use rotating impellers to change airflow direction.

Read More

Axial fans and ventilation fans serve different purposes in air movement systems. Axial fans are designed to move large volumes of air parallel to their rotating shaft, making them ideal for high-airflow, low-pressure applications. Ventilation fans, however, focus on improving air quality by exchanging stale air with fresh air in enclosed spaces.

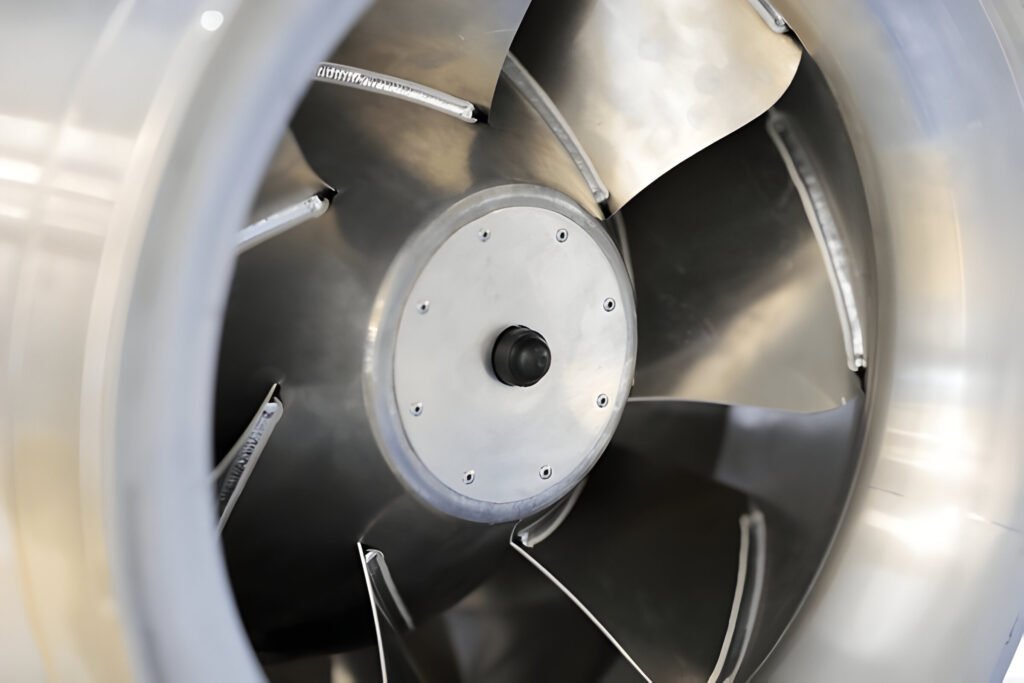

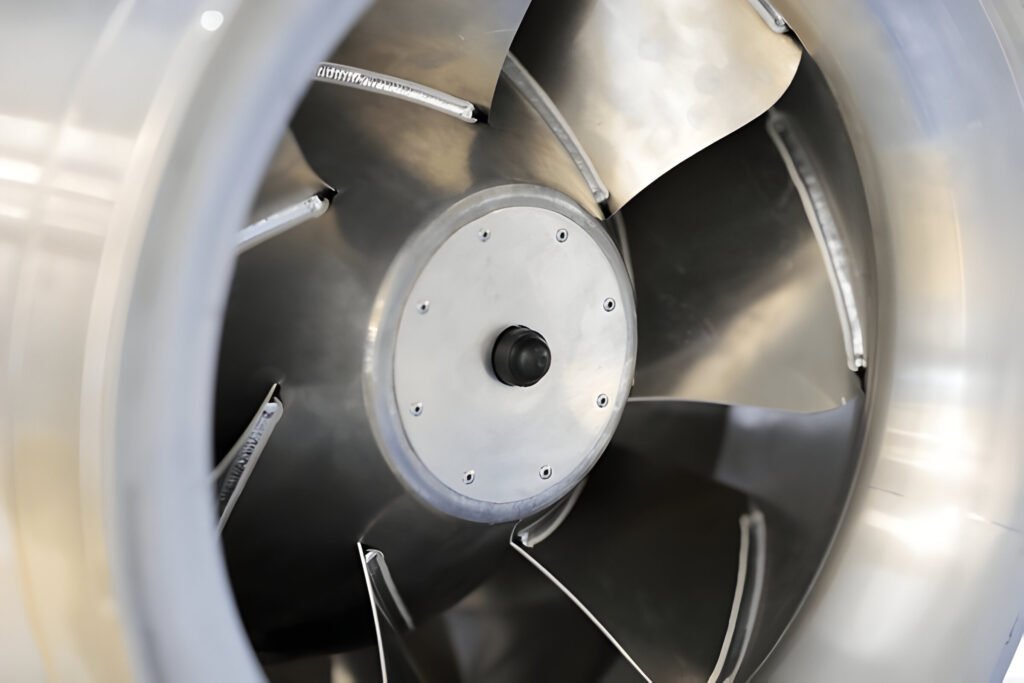

Axial fans are a type of air-moving device that propels air along the axis of the fan’s rotation. These fans are designed to move large volumes of air at relatively low pressures, making them ideal for applications such as ventilation, cooling, and exhaust systems. The blades of an axial fan are typically mounted on a central hub and are shaped to efficiently push air in a straight line, parallel to the shaft about which the blades rotate.

Axial fans operate by drawing air in parallel to the shaft on which the blades are mounted, and expelling it in the same direction. The blades of an axial fan are designed to create a pressure difference between the inlet and outlet sides of the fan, causing air to flow through the fan housing. As the blades rotate, they generate lift and drag forces that move the air in a straight line, parallel to the fan’s axis of rotation.

Propeller fans, a type of axial fan, drive ventilation in industrial settings, warehouses, and large commercial spaces. Their blades resemble aircraft propellers, giving them their name. These fans move large volumes of air quickly and efficiently. They excel in applications requiring high airflow rates but operate only in low-pressure situations.

Propeller fan design prioritizes air movement over pressure generation. The blades typically have a low pitch angle, allowing them to spin rapidly and displace air effectively. This design makes them suitable for spaces with minimal airflow resistance.

Tube axial fans represent an advanced design in cylindrical powerhouses. They improve upon basic propeller models by encasing the fan in a tube-like housing. This housing guides airflow, enhancing efficiency and pressure capabilities. These fans excel in applications requiring higher static pressure, such as HVAC systems and industrial ventilation.

Tube axial fans operate by drawing air parallel to the fan’s axis and then discharging it in the same direction. This design principle contributes to their ability to move large volumes of air efficiently. The fan blades are typically pitched at an angle to optimize airflow and pressure output.

Vane axial fans outperform tube axial models by incorporating guide vanes before or after the impeller. These vanes straighten airflow and boost efficiency. Applications demanding higher pressures and precise airflow control benefit from vane axial fans.

Enhanced aerodynamics reduce noise and improve overall performance. This makes vane axial fans suitable for industrial ventilation, wind tunnels, and HVAC systems.

Axial fans cool large spaces by moving high volumes of air, regulating temperatures efficiently. Data centers use axial fans to maintain optimal conditions for servers and heat-generating equipment.

These fans ventilate factories, warehouses, and commercial buildings, ensuring proper air circulation and comfortable working environments. Underground parking garages employ axial fans to remove exhaust fumes and maintain air quality.

In exhaust systems, axial fans remove fumes, dust, and contaminants from industrial work areas. Residential applications include bathroom exhaust systems and kitchen range hoods for moisture and odor removal.

The automotive industry utilizes axial fans in engine cooling systems and car radiators to prevent overheating. HVAC systems incorporate axial fans in air conditioning units and cooling towers for efficient heat exchange and temperature control.

Ventilation fans are mechanical devices designed to regulate air circulation and maintain optimal indoor air quality by removing stale, humid, or polluted air from enclosed spaces. These fans work by drawing in fresh outdoor air while simultaneously exhausting unwanted indoor air, helping to control moisture levels, reduce odors, and prevent the buildup of harmful pollutants such as mold, mildew, and volatile organic compounds (VOCs).

Ventilation fans are designed to remove stale, humid, or contaminated air from an enclosed space and replace it with fresh air from outside. The basic principle behind how ventilation fans work is simple: they create a pressure difference between the inside and outside of a building, causing air to flow from high-pressure areas to low-pressure areas.

Most ventilation fans consist of an electric motor that spins a set of blades, creating a centrifugal force that pulls air into the center of the fan and pushes it out through the edges. As the fan blades rotate, they create a low-pressure zone at the center of the fan, which draws air in from the surrounding area. The air is then forced out of the fan and through a duct or opening, creating a continuous flow of air.

Ceiling fans circulate air within rooms, creating cooling effects through evaporation. They differ from ventilation fans, which bring in fresh air and remove stale air. Ceiling fans primarily enhance comfort and can complement ventilation systems.

These devices don’t ventilate spaces but distribute air effectively. They create air movement, which increases evaporation on skin surfaces, resulting in a perceived cooling effect. This process can make a room feel up to 4°F cooler without changing the actual temperature.

Wall-mounted ventilation fans remove moisture, odors, and stale air from bathrooms, kitchens, and laundry rooms. Installed directly into walls near ceilings, these fans vent air outside. These fans prevent mold growth and improve indoor air quality.

Inline ventilation fans provide efficient air circulation solutions. These fans install within ductwork, making them suitable for spaces where visibility is not a concern. Bathrooms, kitchens, and multi-room setups benefit from inline fan installations.

Inline fans move large air volumes quietly. Their design allows for effective air movement without the noise associated with traditional fans. This feature makes them ideal for residential and commercial applications where noise reduction is a priority.

In homes, ventilation fans are common in bathrooms, kitchens, and attics. They expel humid air and prevent mold growth, protecting building structures from moisture damage.

Industrial facilities use ventilation fans to eliminate fumes, dust, and heat generated by machinery. Warehouses employ these fans to regulate temperature and remove harmful gases. Parking garages rely on ventilation systems to expel vehicle exhaust.

Agricultural applications include barns and greenhouses, where fans control temperature, humidity, and air circulation for optimal plant and animal health.

Ventilation fans are essential in humid climates and areas prone to water damage. They reduce the risk of structural issues caused by excessive moisture.

Axial fans generate airflow parallel to the fan’s axis, producing a concentrated, high-velocity stream. This makes them effective for cooling electronic components and ventilating long ducts. Axial fans typically deliver higher airflow rates but lower pressure, suiting low-resistance systems.

Ventilation fans, often using centrifugal force, create a diffused airflow pattern. They draw air in centrally and expel it radially, distributing air more widely. This design suits general room ventilation and applications requiring air movement across larger areas. Ventilation fans generate higher pressure, better overcoming system resistance.

Axial fans move air parallel to their rotational axis, pushing it through in a linear path. This design suits applications requiring direct air movement between points.

Ventilation fans employ complex airflow patterns. They draw air from multiple directions and expel it in a specific direction. This multidirectional capability enables the removal of stale air and its replacement with fresh air.

Axial fans use propeller-like blades on a central hub, rotating around an axis parallel to airflow. These blades are made of lightweight materials such as plastic or aluminum for efficiency. The motor is housed within the hub, creating a streamlined profile. Axial fans are simpler and more compact, facilitating easier installation and maintenance.

Ventilation fans often employ a centrifugal design with a wheel featuring forward-curved or backward-inclined blades. This wheel is enclosed in a scroll-shaped housing that directs airflow. The motor is typically mounted externally, separate from the fan wheel. Ventilation fans are more robust and handle higher static pressures. They often include additional components like filters, dampers, or heat exchangers, increasing versatility and complexity.

Axial fans consume less power than ventilation fans of similar size and capacity due to their simpler design and fewer moving parts. This reduces friction and energy loss. Axial fans excel at moving large air volumes in low-pressure environments, making them suitable for computer cooling or industrial ventilation.

Ventilation fans consume more power but offer higher pressure capabilities. They overcome greater resistance in ducting systems, requiring more energy. Ventilation fans provide better overall air circulation and effectively remove pollutants or moisture from enclosed spaces.

Axial fans generate higher noise levels than ventilation fans due to their design. They produce a high-pitched sound noticeable in quiet environments.

Ventilation fans operate more quietly, utilizing a centrifugal design for smoother airflow. This makes them suitable for residential and office settings where noise reduction is critical.

Axial fans exhibit greater robustness due to their simpler design with fewer moving parts, reducing mechanical failure risks. This makes them suitable for harsh industrial environments and extends their operational life.

Ventilation fans possess more complex designs, incorporating additional components like filters and ductwork. These elements increase maintenance frequency, requiring regular filter cleaning or replacement to maintain optimal performance.

Axial fans offer lower initial costs due to simpler design and fewer components. This makes them cost-effective for basic ventilation in homes and small businesses. Manufacturers pass on savings from lower production costs to consumers.

Ventilation fans have higher upfront prices. Complex designs, additional features, and specialized parts increase manufacturing expenses. However, they often provide better energy efficiency, potentially reducing long-term operating costs. Their durability may also lead to less frequent replacements, offering potential savings over time.

Axial fans perform optimally in applications requiring high airflow and low pressure. They excel in large, open spaces needing air circulation or cooling, such as warehouses, factories, and agricultural buildings.

Cooling towers benefit from axial fans’ efficient heat dissipation capabilities for industrial processes. These fans also suit tunnel ventilation, removing exhaust fumes and maintaining air quality. Data centers rely on axial fans to cool sensitive equipment and prevent overheating.

Applications demanding high-volume, unidirectional airflow favor axial fans. Commercial kitchen exhaust systems use them to remove hot air and odors effectively. HVAC systems in larger buildings employ axial fans for both supply and return air.

Ventilation fans remove moisture, odors, and pollutants from indoor spaces. Use them in bathrooms, kitchens, and laundry rooms with high humidity. Install fans in areas with limited natural airflow like basements, attics, and enclosed garages to prevent mold growth and harmful gas buildup.

Industrial and commercial settings require ventilation fans for air quality standards and worker safety. Factories, warehouses, and workshops use these fans to eliminate fumes, dust, and heat.

Large buildings or complex layouts benefit from ventilation fans integrated into HVAC systems. This ensures proper air exchange throughout schools, hospitals, and office buildings, directly impacting occupant health and comfort.

Axial fans and ventilation fans are not always interchangeable in HVAC systems.

Axial fans typically offer higher energy efficiency for residential use due to their simpler design and lower power requirements.

Both fan types require regular cleaning. Axial fans need frequent blade checks and lubrication. Ventilation fans may require filter replacements and duct inspections.

Both axial and ventilation fans can integrate with smart home automation systems. These fans can be controlled via applications, voice commands, or automated schedules, seamlessly fitting into connected home environments.