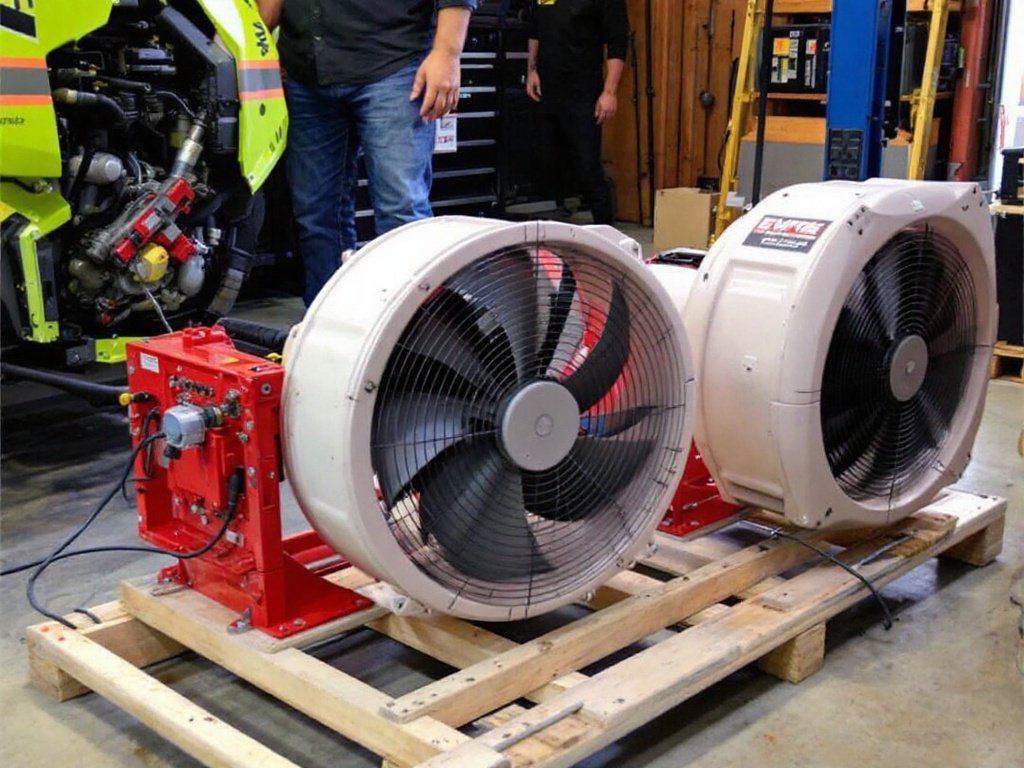

Industrial fans are powerful machines that move large volumes of air to cool, ventilate or exhaust gases from industrial spaces. While these fans are designed and built to withstand the rigors of continuous operation in demanding environments, they can still be susceptible to overheating under certain conditions. Overheating can lead to reduced performance, equipment damage, and even complete failure if not addressed promptly.

In this article, we will explore the factors that can contribute to industrial fan overheating, the signs that indicate a fan is overheating, and the preventive measures that can be taken to mitigate this risk.

Factors Contributing to Industrial Fan Overheating

Several factors can cause an industrial fan to overheat, compromising its performance and longevity. Let’s examine some of the most common culprits:

Blocked Airflow

One of the primary functions of an industrial fan is to move air efficiently. When the airflow is restricted or blocked, the fan has to work harder to maintain the desired air movement, causing the motor to overheat. Blockages can occur due to the accumulation of dust, dirt, or debris on the fan blades, guards, or ductwork. Foreign objects lodged in the fan or collapsed ducts can also obstruct airflow.

Mechanical Issues

Industrial fans are subject to wear and tear over time, and mechanical issues can arise that lead to overheating. Worn bearings, for example, can cause increased friction, generating excess heat. Misaligned or imbalanced fan blades can also put additional strain on the motor, causing it to work harder and overheat. Loose or damaged belts can slip, reducing the fan’s efficiency and causing the motor to overheat as it tries to compensate.

Inadequate Ventilation

Industrial fans generate heat as they operate, and this heat needs to be dissipated to prevent overheating. If the fan is installed in an area with inadequate ventilation, heat can build up around the motor, leading to overheating. This is particularly problematic in enclosed spaces or where multiple heat-generating machines are operating in close proximity.

Electrical Problems

Electrical issues can also contribute to industrial fan overheating. Over or under-voltage conditions, phase imbalances, and electrical surges can all cause the fan motor to draw excessive current and generate heat. Loose or corroded electrical connections can increase resistance, causing the motor to work harder and overheat. Failure of the motor’s insulation due to age, heat, or moisture can also lead to electrical shorts and overheating.

Signs of Industrial Fan Overheating

Recognizing the signs of industrial fan overheating is crucial for timely intervention and prevention of equipment damage. Here are some key indicators to watch out for:

Unusual Noises or Vibrations

If your industrial fan starts producing unusual noises, such as squealing, grinding, or clunking sounds, it could be a sign of mechanical issues that can lead to overheating. Increased vibrations can also indicate problems like imbalanced fan blades or worn bearings, which can cause the motor to overheat if left unchecked.

Reduced Airflow or Performance

A noticeable decrease in the fan’s airflow or overall performance can suggest that the fan is struggling due to blockages, mechanical issues, or motor problems. If the fan seems to be working harder but moving less air, it’s a clear sign that something is amiss and overheating could be imminent.

Visible Damage to Fan Components

Regular visual inspections of your industrial fan can reveal physical damage that may contribute to overheating. Look for signs of wear, cracks, or deformation on the fan blades, guards, and housing. Check for frayed or damaged belts, and inspect electrical wiring and connections for any signs of overheating, such as discoloration or melted insulation.

Activation of Thermal Protection Devices

Many industrial fans are equipped with thermal protection devices that automatically shut down the fan if it reaches a critical temperature threshold. If your fan keeps tripping its thermal protection and shutting off, it’s a clear indication that overheating is occurring.

Preventive Measures

Preventing industrial fan overheating is far more effective than dealing with the consequences of an overheated fan. Here are some preventive measures you can take:

Regular Maintenance

Establishing and following a regular maintenance schedule is crucial for keeping your industrial fan in optimal condition. This includes cleaning the fan blades, guards, and ductwork to prevent airflow blockages. Inspect and replace worn belts, bearings, and other mechanical components before they fail. Check electrical connections and wiring for any signs of wear or damage.

Proper Lubrication

Adequate lubrication is essential for reducing friction and heat generation in moving parts. Follow the manufacturer’s recommendations for the type and frequency of lubrication required for your specific fan model. Over or under-lubrication can both lead to problems, so it’s important to get it right.

Airflow Management

Ensure that your industrial fan has adequate space around it for proper ventilation. Avoid installing fans in confined spaces or near other heat-generating equipment whenever possible. Use ductwork of appropriate size and design to minimize airflow resistance and turbulence. Regularly check and clean ductwork to prevent blockages that can restrict airflow.