Industrial fans are powerful tools used in various settings, such as warehouses, factories, and workshops, to provide ventilation and maintain a comfortable working environment. These fans are designed to operate for extended periods, but the question remains: is it safe and cost-effective to leave an industrial fan running all night?

In this article, we will explore the safety considerations, energy consumption, and potential alternatives to running an industrial fan continuously.

Safety Considerations

When deciding whether to leave an industrial fan on all night, safety should be the primary concern. There are several factors to consider, including electrical safety, fire hazards, and proper placement of the fan.

Electrical safety

Before leaving a fan on overnight, check that the wiring and outlets are in good condition and can support the fan’s power requirements. Overloading the electrical system can lead to short circuits, electrical fires, and other hazards.

Additionally, ensure that the fan is properly grounded and equipped with a ground fault circuit interrupter (GFCI) to protect against electrical shocks.

Fire hazards

Industrial fans generate heat during operation, which can pose a fire risk if not properly monitored. Accumulation of dust, debris, or flammable materials near the fan can increase the likelihood of a fire. To mitigate this risk, regularly clean the fan and its surroundings, and keep the area clear of combustible materials.

It is also essential to check the fan for any signs of wear or damage, such as frayed cords or loose connections, which can cause sparks or electrical fires. If any issues are detected, the fan should be repaired or replaced before being left on overnight.

Placement of the fan

Ensure that the fan is positioned away from walls, curtains, or other objects that could obstruct airflow or cause overheating. The fan should also be placed on a stable, level surface to prevent it from tipping over or vibrating excessively.

Consider the fan’s proximity to workers or equipment, as the strong airflow could cause discomfort or interfere with work processes. Adjust the fan’s position and angle to direct the airflow where it is most needed without creating any hazards.

Energy Consumption and Cost

Understanding the fan’s power usage and calculating the associated expenses can help determine whether leaving the fan on overnight is economically feasible.

Power usage of industrial fans

Industrial fans come in various sizes and power ratings, consuming anywhere from a few hundred to several thousand watts of electricity. The fan’s power consumption depends on factors such as its size, speed, and efficiency. To determine the fan’s power usage, refer to the manufacturer’s specifications or the information provided on the fan’s label.

Calculating the cost of running a fan all night

To calculate the cost of running an industrial fan all night, you will need to know the fan’s power consumption, the electricity rate (cost per kilowatt-hour), and the number of hours the fan will be running. Use the following formula:

Cost = Power (kW) × Time (hours) × Electricity rate ($/kWh)

For example, if a fan consumes 1.5 kW of power, runs for 12 hours overnight, and the electricity rate is $0.10/kWh, the cost would be:

Cost = 1.5 kW × 12 hours × $0.10/kWh = $1.80 per night

For instance, if the fan is used every night for a month (30 days), the monthly cost would be:

Monthly cost = $1.80 per night × 30 days = $54

Alternatives to Running a Fan All Night

If running an industrial fan all night proves to be unsafe or cost-prohibitive, there are several alternatives to consider that can help maintain a comfortable working environment while reducing energy consumption and costs.

Setting a timer for limited hours of operation

One alternative is to use a timer to control the fan’s operating hours. By setting the timer to run the fan only during the hottest parts of the day or when the workspace is occupied, you can reduce energy consumption while still providing adequate ventilation and cooling. Many industrial fans come with built-in timer functions, or you can use an external timer device to control the fan’s operation.

Investing in a fan with a thermostat or automatic shut-off feature

Another option is to invest in an industrial fan equipped with a thermostat or automatic shut-off feature. These fans can monitor the ambient temperature and adjust their operation accordingly, turning on when the temperature rises above a set threshold and shutting off when the desired temperature is reached. This ensures that the fan runs only when necessary, saving energy and reducing costs.

Exploring other cooling or ventilation options

In some cases, running an industrial fan all night may not be the most effective or efficient solution for maintaining a comfortable working environment. It may be worth exploring alternative cooling or ventilation options that can provide better results with lower energy consumption.

For example, installing a high-volume, low-speed (HVLS) fan can help circulate air more efficiently, covering a larger area with a single fan and reducing the need for multiple smaller fans. HVLS fans are designed to operate at lower speeds, consuming less energy while providing effective cooling and ventilation.

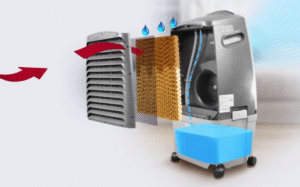

Another option is to invest in a more energy-efficient cooling system, such as an evaporative cooler or air conditioner. These systems can provide more targeted cooling and temperature control, allowing you to maintain a comfortable environment without relying on continuous fan operation.

Improving the building’s insulation and sealing air leaks can also help reduce the need for continuous fan operation by minimizing heat transfer and maintaining a more stable indoor temperature. This can be achieved through measures such as installing weather stripping, sealing gaps around windows and doors, and adding insulation to walls and ceilings.