Axial Fan Vs Radial Fan: What Is the Difference

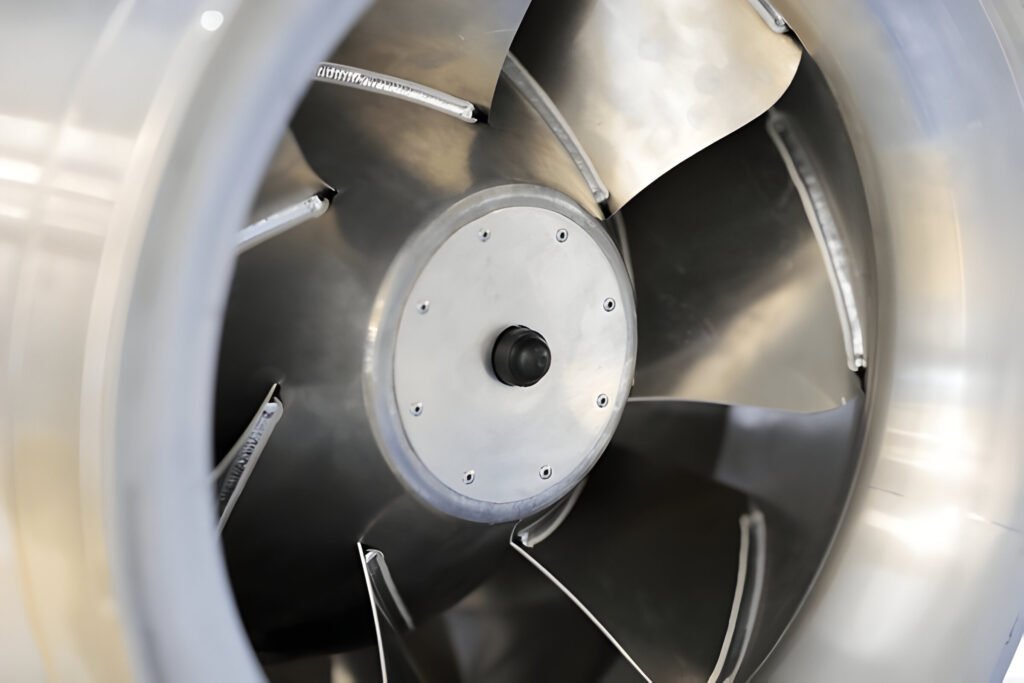

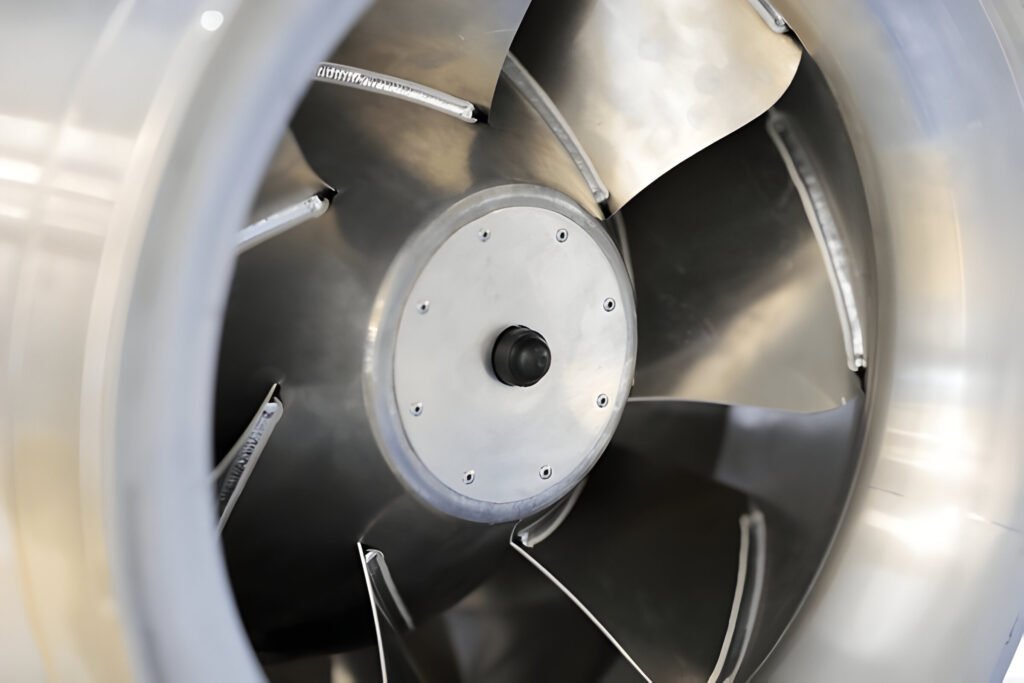

Axial fans move air parallel to the shaft, while radial fans move air perpendicular to the shaft.

Read More

Axial fans utilize a range of materials to meet diverse performance requirements. Common choices include aluminum alloys for lightweight strength, steel for durability, plastics for chemical resistance, and composites for high-performance applications.

Aluminum and its alloys are primary materials for axial fans due to their lightweight strength, corrosion resistance, and thermal conductivity. The low density of aluminum reduces fan weight, enhancing energy efficiency and installation ease.

Common aluminum alloys for axial fans include series 6061 and 5052. These alloys offer improved strength and formability over pure aluminum while resisting environmental factors. Their rapid heat dissipation capabilities maintain optimal fan performance.

Aluminum’s manufacturing versatility allows for casting, extruding, or machining into complex shapes, enabling intricate fan blade designs. The material’s natural oxide layer provides inherent corrosion protection, further enhanced through anodizing. This characteristic makes aluminum fans suitable for harsh or humid environments.

Carbon steel, galvanized steel, and stainless steel are the three main types of steel used in axial fan construction.

Carbon steel offers high strength and durability at a lower cost. It suits industrial applications where corrosion resistance is not a primary concern. Fan blades and housings for heavy-duty fans often use carbon steel.

Galvanized steel is carbon steel coated with zinc, providing improved corrosion resistance. It excels in outdoor or humid environments, as the zinc layer protects against rust. Fan housings, supports, and some blade designs frequently use galvanized steel.

Stainless steel, an alloy containing chromium, delivers superior corrosion resistance and aesthetic appeal. It performs well in food processing, pharmaceutical, and marine applications. High-end fan blades, impellers, and housings commonly use stainless steel.

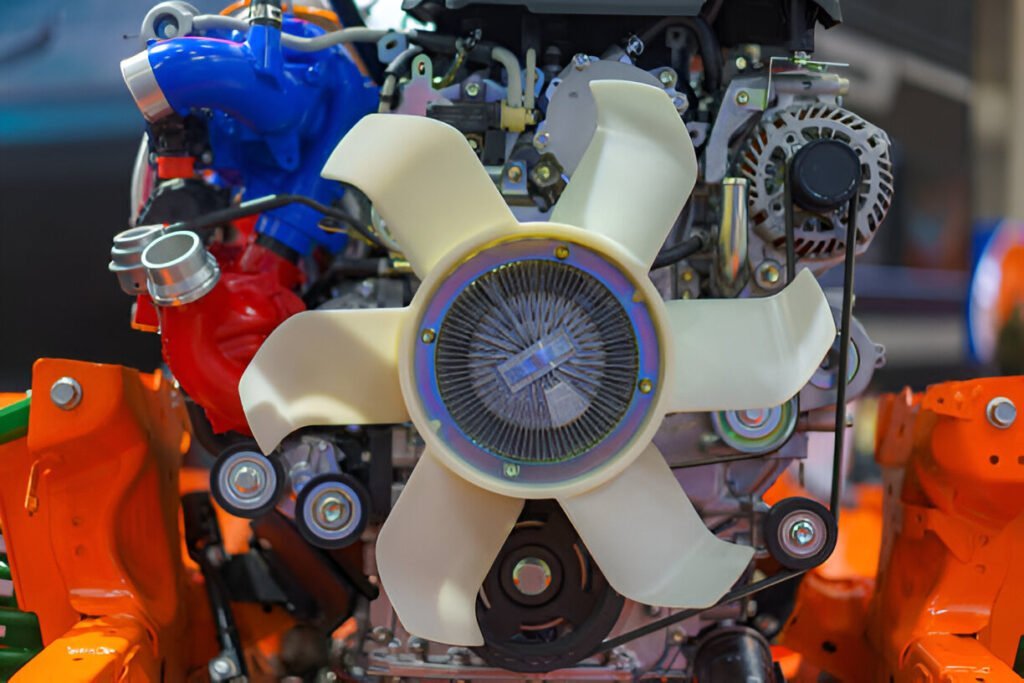

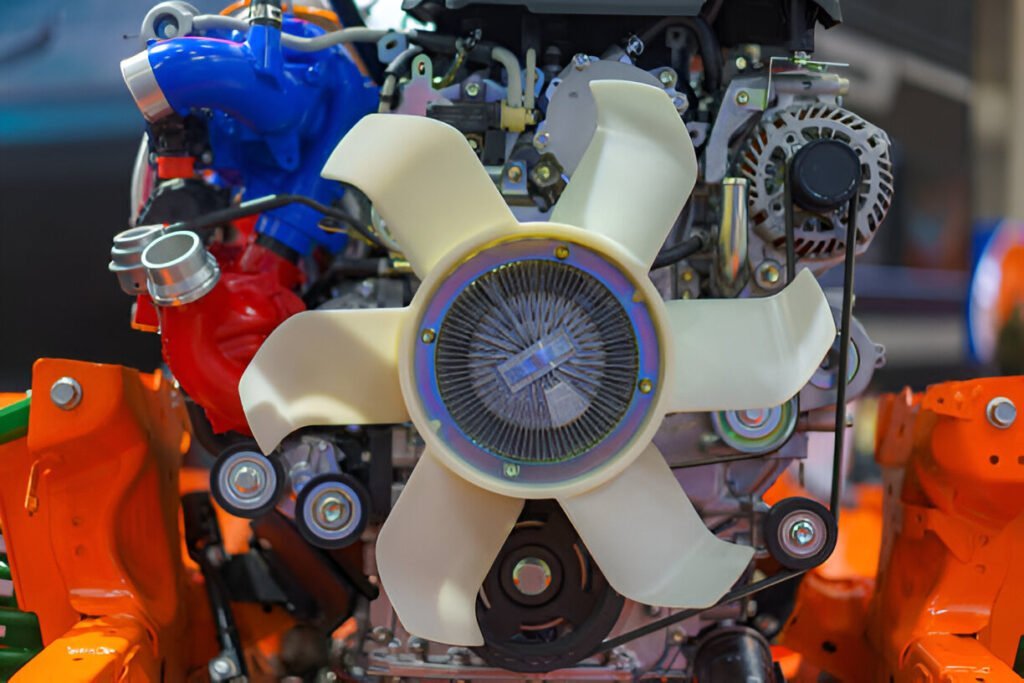

Polypropylene and reinforced plastics provide corrosion resistance and lightweight properties, making them suitable for chemical processing and marine applications. Glass-filled polypropylene, a type of reinforced plastic, enhances strength and rigidity. These materials withstand high temperatures and maintain dimensional stability, adapting to various industrial environments.

Polypropylene fans resist chemical corrosion, making them ideal for aggressive atmospheres. They also offer a lower weight-to-strength ratio compared to metal alternatives, reducing overall system load.

Glass-fiber reinforced polymers (GFRP) offer superior strength-to-weight ratio in axial fan manufacturing. GFRP resists corrosion and maintains dimensional stability. This composite material combines polymer resins with glass fibers, enhancing mechanical properties.

GFRP fans weigh less than metal alternatives, reducing energy consumption and noise levels. They perform well in harsh environments, making them suitable for applications requiring durability.

Composite materials enhance axial fan performance through innovative combinations of components. Carbon fiber reinforced polymers (CFRP) provide high strength-to-weight ratios, enabling larger, more efficient fan blades. Hybrid composites blend carbon and glass fibers to balance cost and performance.

Ceramic matrix composites (CMCs) excel in extreme temperature environments, maintaining strength and shape where traditional materials fail. Metal matrix composites (MMCs) resist corrosion by combining metal alloys with ceramic reinforcements.

Nanocomposites incorporate nanoscale particles to improve wear resistance, reduce noise, and increase thermal conductivity in fan components. These advanced materials push the boundaries of axial fan capabilities.

Aluminum blades provide lightweight construction and corrosion resistance, suitable for general-purpose use.

Cast aluminum, steel, and high-strength plastics are common hub materials in axial fans.

Hub plates often use similar materials to hubs.

Axial fan housings utilize metals and plastics for optimal performance and durability.

Temperature resistance dictates material selection for axial fans in high-heat environments. Choose materials that withstand expected temperature ranges without warping or degrading. Specialty alloys or ceramics suit extreme temperatures.

Corrosion resistance matters in humid, chemically exposed, or saltwater environments. Select materials resistant to rapid deterioration. Stainless steel, aluminum alloys, or specialized coatings provide effective corrosion protection.

Spark resistance is essential when fans may encounter flammable gases or dust. Use non-ferrous materials like aluminum or brass to minimize spark risk. Consider composite materials for combined spark resistance and strength in specific applications.

Axial fan materials face constant challenges in harsh environments due to humidity, chemical exposure, and airborne particles.

High humidity leads to corrosion and rust in metal components. Stainless steel and aluminum alloys offer better resistance to moisture-related degradation.

Chemical exposure necessitates materials that withstand corrosive gases or liquids. Specialized coatings or composite materials protect against chemical attacks.

Airborne particles cause abrasion and wear on fan components. Hardened steels or ceramics resist erosion from dust, sand, or other particulates in high-particulate environments.

Steel and aluminum offer affordability for budget-conscious projects. However, more expensive materials can provide better efficiency and longer lifespans. Composite materials, despite higher initial costs, may lead to energy savings and reduced maintenance over time.

Lighter materials enhance performance and efficiency. Aluminum offers low weight and good strength-to-weight ratio, enabling faster blade acceleration and deceleration, reducing energy use and improving responsiveness.

Weight affects blades, motor, and housing. Carbon fiber-reinforced polymers provide excellent strength and minimal weight, ideal for high-performance applications.

Lighter materials reduce vibrations, while stiffer ones minimize resonance. Composite blades often produce less noise than metal ones due to superior damping properties.

Recycled materials can be effectively used in axial fan manufacturing. Recycled plastics and metals are suitable for fan blades and housings, maintaining performance while reducing costs and environmental impact. This approach is both economical and environmentally responsible.