Product Introduction

The A100 AC/DC variable frequency brushless window fan redefines indoor comfort with advanced technology. Powered by a brushless DC motor, it ensures whisper-quiet operation, minimal energy consumption, and extended durability. Ideal for homes or offices, its sleek, compact design merges functionality with aesthetics. Enjoy silent, energy-efficient cooling all summer long.

Use

This innovative device is a versatile air quality enhancement system designed to cater to both industrial and household needs, featuring a unique Dual Power Mode Compatibility that sets it apart from conventional air treatment equipment.

Product parameters

| Model | Voltage (V) | Frequency (HZ) | Power (W) | Speed (r/min) | Air volume (m³/h) |

| A100(Style H) | 220 | 50 | 5 | 2300 | 100 |

| A100(Style G) | 220 | 50 | 5 | 2300 | 100 |

| A100 | 220 | 50 | 15 | 2300 | 100 |

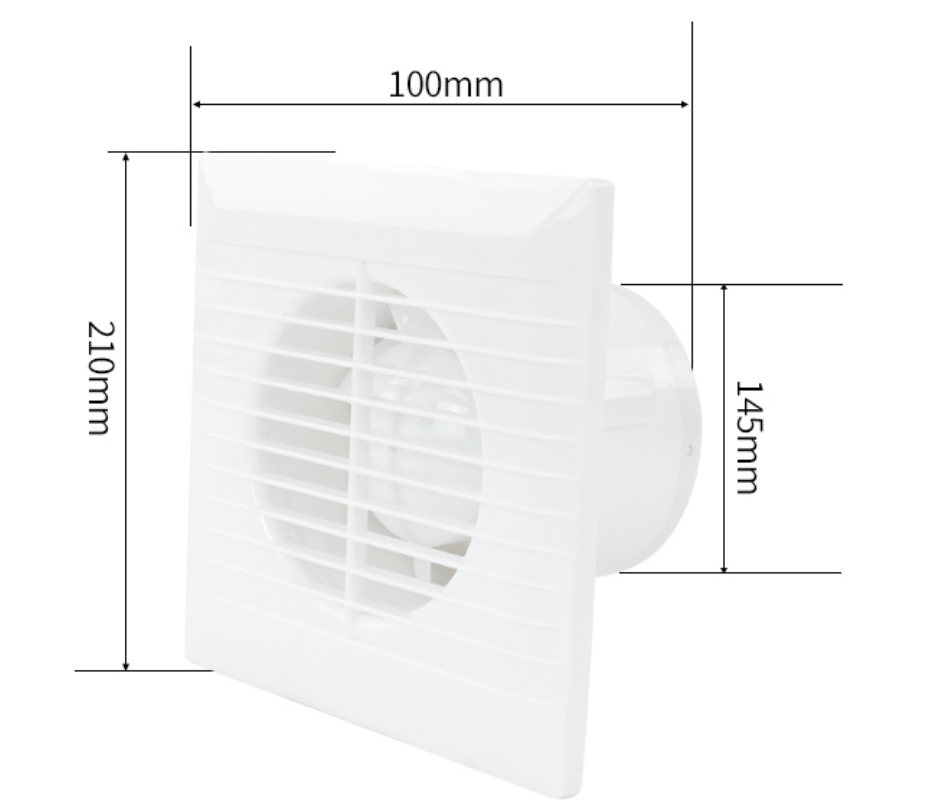

Dimension

Product Features

- The device is engineered to operate seamlessly in two distinct power modes. This flexibility allows it to adapt to different power supply scenarios. In an industrial setting where power requirements may be high and stable, it can utilize a high – power mode to deliver maximum performance for tasks like welding smoke extraction. In a household environment, where energy conservation is often a priority, it can switch to a lower – power mode, effectively removing formaldehyde and dehumidifying while consuming less electricity.

- At the heart of the device lies a high – quality copper core motor. Copper is an excellent conductor of electricity, which means the motor can operate efficiently with minimal energy loss. This not only reduces the overall energy consumption of the device but also ensures a longer lifespan. The copper core motor provides the necessary power to drive the fan and other components, maintaining consistent performance over time.

- The high air volume design is a crucial aspect of the device’s functionality. It is capable of moving a large volume of air per unit of time, which is essential for both industrial smoke extraction and household air purification. In an industrial workshop, the high air volume helps quickly capture and remove welding smoke, preventing it from spreading and posing health risks to workers. In a home, it ensures that a sufficient amount of air is circulated through the filtration system for effective formaldehyde removal and dehumidification.

- In industrial environments, welding operations generate a significant amount of harmful smoke and fumes. This device acts as a powerful welding smoke extractor. Its high air volume and specialized filtration system (implied by the overall design) can efficiently capture and filter out the fine particles and toxic gases produced during welding. This helps maintain a clean and safe working environment, reducing the risk of respiratory diseases and other health issues among workers.

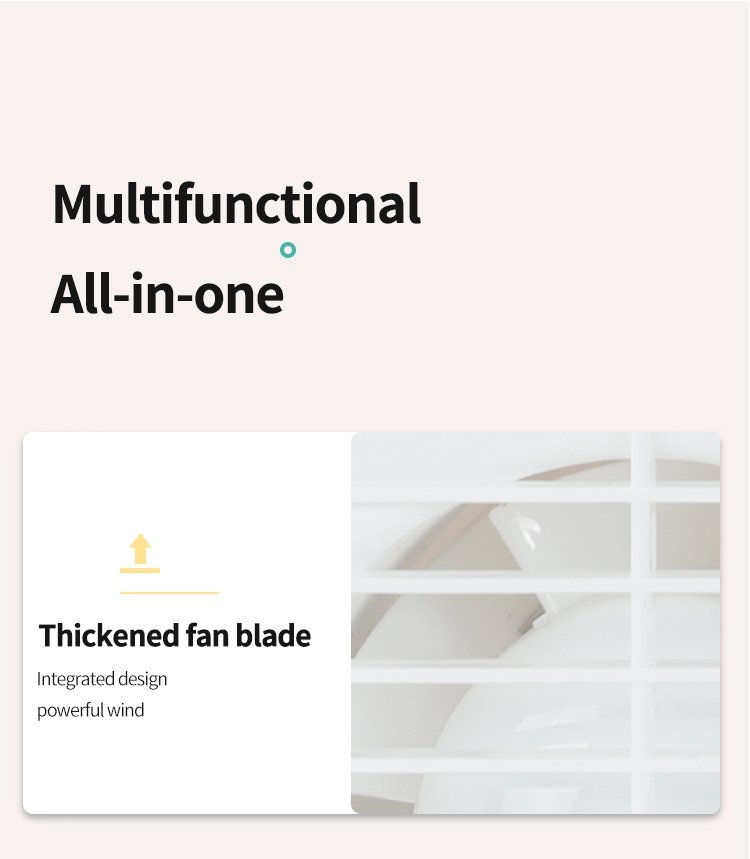

- The thickened fan blades are designed to withstand the high – speed rotation required for the high air volume operation. They are more durable and less likely to deform or break under the stress of continuous use. This ensures a stable and reliable airflow, which is essential for the device to perform its functions effectively over an extended period.

Note: This multi – functional air quality enhancement device, with its Dual Power Mode Compatibility, copper core motor, high air volume design, and other features, is a highly versatile and effective solution for improving air quality in both industrial and household settings.

Product installation and instructions

- Verify all components: main unit, mounting brackets, sliding rails, 90° angle connectors, screws, and power adapter. Check for physical damage and ensure all parts are included.

- Clean filters monthly. Check fan blades for debris. Annual professional inspection recommended.

- Disconnect power before maintenance. Avoid touching the motor during operation to prevent burns.

Product images

Request a Quote Now

Our team will get back to you within 24 hours.