Product Introduction

The high-pressure centrifugal fan 4-72 is a widely used ventilation equipment in the industrial field. It is made of high-quality steel plates, with a sturdy and durable structure, and features high efficiency, low noise, and smooth operation. This fan is suitable for indoor ventilation and air exchange in general factories and large buildings, and can transport gases that are non self igniting, harmless to human health, and non corrosive to steel. It has a wide performance range, high traffic, and high total pressure, and can be customized according to user needs. The 4-72 high-pressure centrifugal fan also has the advantages of easy maintenance, durability, and is one of the indispensable ventilation equipment in industrial production.

Product parameters

| Model | Blade diameter (mm) | Power(kw) | Air volume (m ³/ h) | Wind pressure (Pa) | Speed (r/min) |

| 2.8A | 280 | 1.5 | 1131-2356 | 994-606 | 2900 |

| 3.2A | 320 | 2.2 | 1688-3517 | 1300-792 | 2900 |

| 1.1 | 884-1758 | 324-198 | 1450 | ||

| 3.6A | 360 | 3 | 2664-5268 | 1578-989 | 2900 |

| 1.1 | 1322-2634 | 393-247 | 1450 | ||

| 4.0A | 400 | 5.5 | 4012-7419 | 2014-1320 | 2900 |

| 1.1 | 2006-3709 | 501-329 | 1450 | ||

| 4.5A | 450 | 7.5 | 5712-10562 | 2554-1673 | 2900 |

| 1.1 | 2856-5281 | 636-416 | 1450 | ||

| 5A | 500 | 15 | 7728-15455 | 3187-2019 | 2900 |

| 2.2 | 3864-7728 | 790-502 | 1450 | ||

| 5.6A | 560 | 3 | 7062-9885 | 957-759 | 1450 |

| 6A | 600 | 4 | 6677-13353 | 1139-724 | 1450 |

| 1.5 | 4420-8841 | 498-317 | 960 | ||

| 7.1A | 710 | 11 | 12676-20513 | 1573-1168 | 1450 |

| 3 | 8392-13581 | 689-512 | 960 | ||

| 6D | 600 | 4 | 6677-13353 | 1139-724 | 1450 |

| 1.5 | 4420-8841 | 498-317 | 960 | ||

| 8D | 800 | 18.5 | 15826-29344 | 2032-1490 | 1450 |

| 5.5 | 10478-19428 | 887-651 | 960 | ||

| 10D | 1000 | 55 | 40441-56605 | 3202-2532 | 1450 |

| 18.5 | 26775-37476 | 1395-1104 | 960 | ||

| 7.5 | 20360-27497 | 805-637 | 960 | ||

| 12D | 1200 | 45 | 46267-64759 | 2013-1593 | 960 |

| 18.5 | 35182-49244 | 1169-919 |

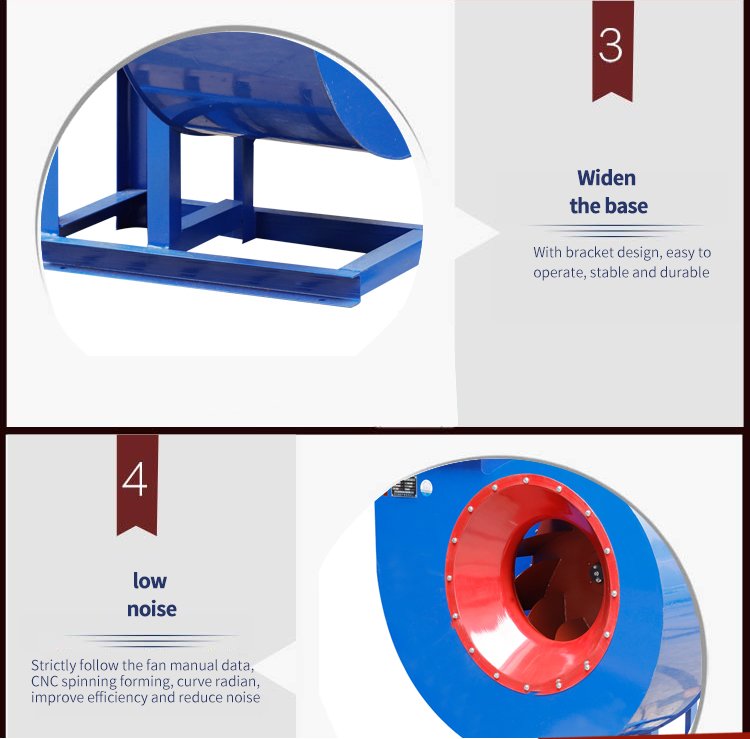

Product Features

- Efficient ventilation: This fan has strong air delivery capacity and can achieve rapid ventilation and air exchange in large areas of space in a short period of time, improving indoor air quality.

- Pressure Stability: The high-pressure design allows the fan to maintain a stable outlet pressure during operation, making it suitable for ventilation systems that require overcoming significant resistance.

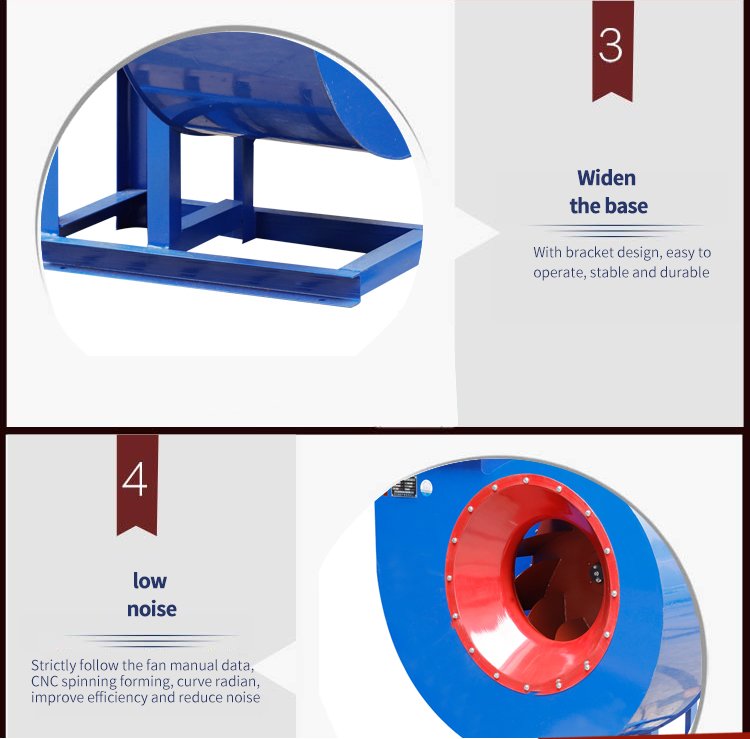

- Low noise operation: By optimizing the fan structure and adopting noise reduction technology, the noise generated by the 4-72 high-pressure centrifugal fan during operation is relatively low and will not interfere with the working environment.

- Energy saving and environmental protection: The fan adopts an efficient motor and energy-saving design, which can significantly reduce energy consumption, reduce operating costs, and meet environmental protection requirements.

- Strong adaptability: The 4-72 high-pressure centrifugal fan is suitable for various working environments and media, and can be customized according to user needs to meet the ventilation needs of different industries.

Product installation and instructions

The installation of high-pressure centrifugal fan 4-72 needs to be carried out by professionals to ensure the stability and safe operation of the fan. Before installation, it is necessary to check whether all components of the fan are intact, select a suitable installation location based on the site conditions, and reserve sufficient space for maintenance and repair. During the installation process, it should be ensured that the inlet and outlet pipes of the fan are tightly connected to avoid air leakage. Electrical connections should be completed by professional electricians to ensure correct wiring and reliable grounding. After installation, conduct a trial run to check if the fan runs smoothly and if there are any abnormal vibrations or noises. Please strictly follow the manufacturer’s installation guidelines and safety regulations to ensure the safe and efficient operation of the fan.

Product images

Request a Quote Now

Our team will get back to you within 24 hours.