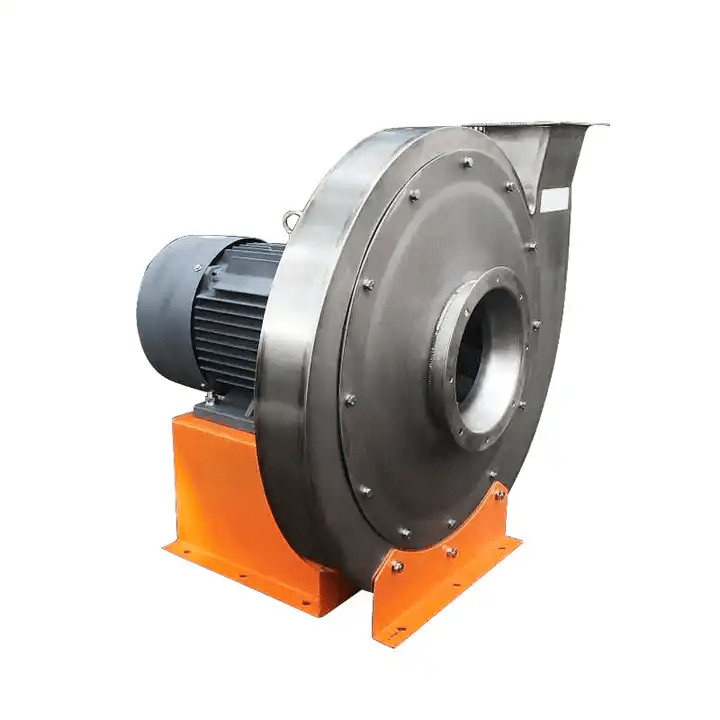

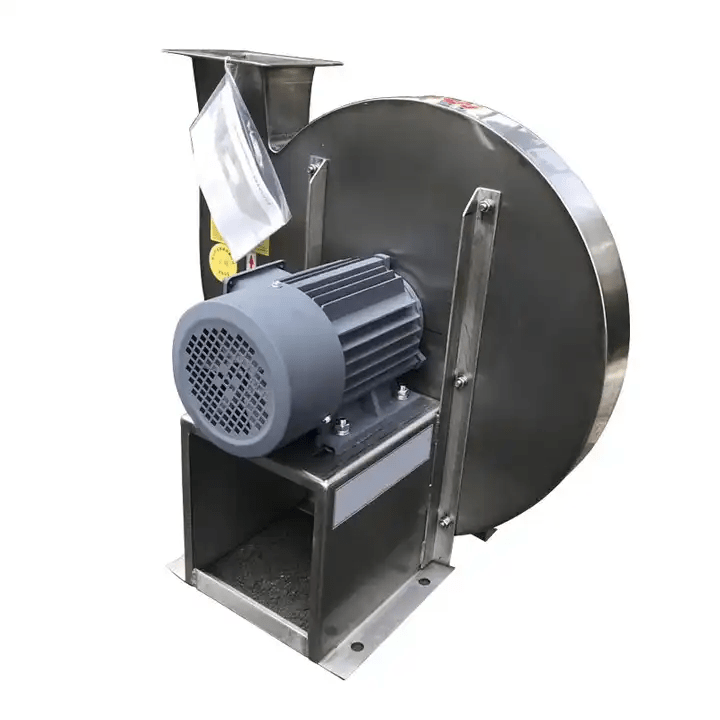

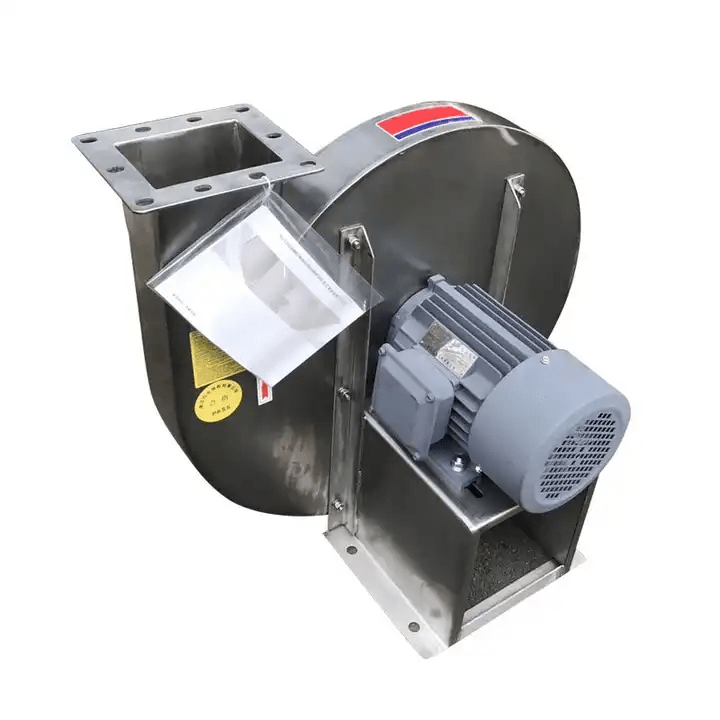

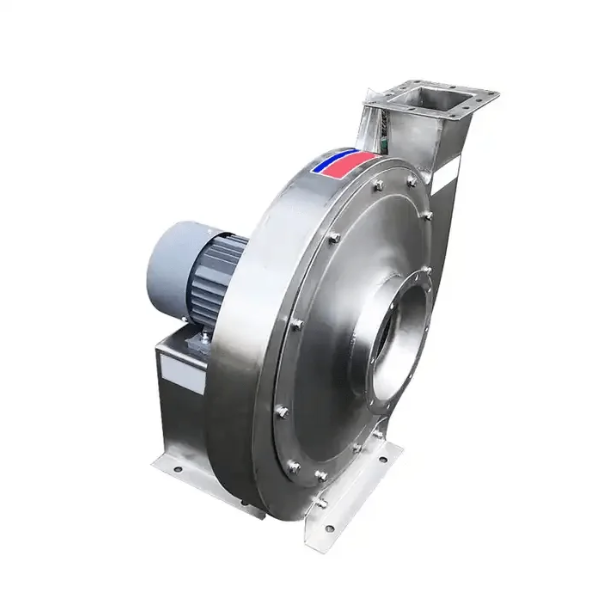

Product Introduction

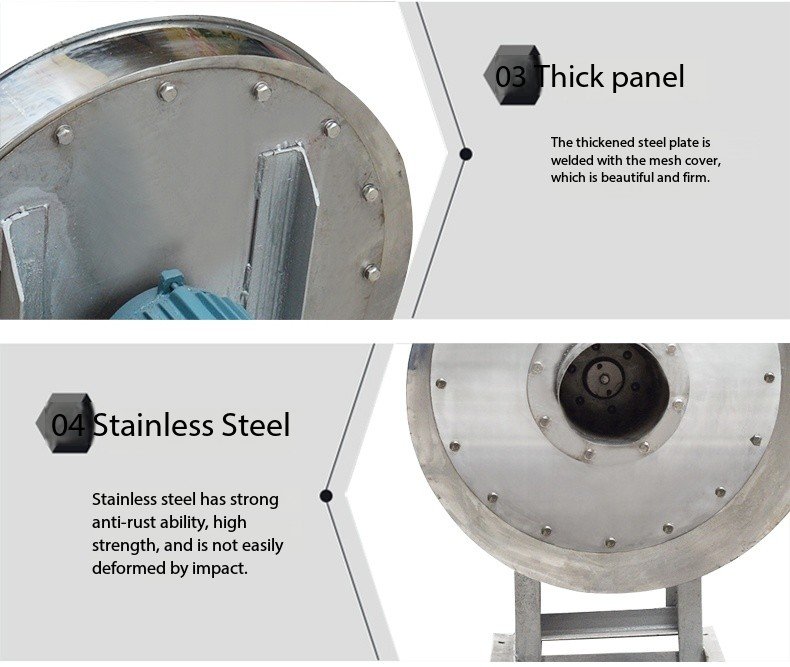

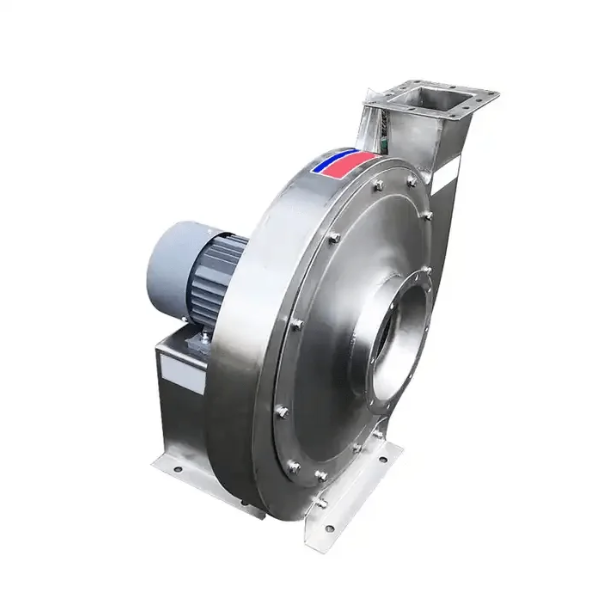

Stainless steel centrifugal fan 9-19 is an efficient ventilation equipment widely used in various industrial occasions. It is made of stainless steel material and has the characteristics of corrosion resistance and high temperature resistance. It is suitable for transporting gases that are non corrosive, non self igniting, non explosive, and do not contain viscous substances. The 9-19 type fan has the advantages of high efficiency, low noise, flat performance curve, and wide high-efficiency zone, which can meet the ventilation needs under different working conditions. Its single suction design comes with multiple machine numbers and rotation direction options, which can be customized according to user needs. The fan has a compact structure, is easy to install and maintain, and is an important equipment in the field of industrial ventilation.

Structural features

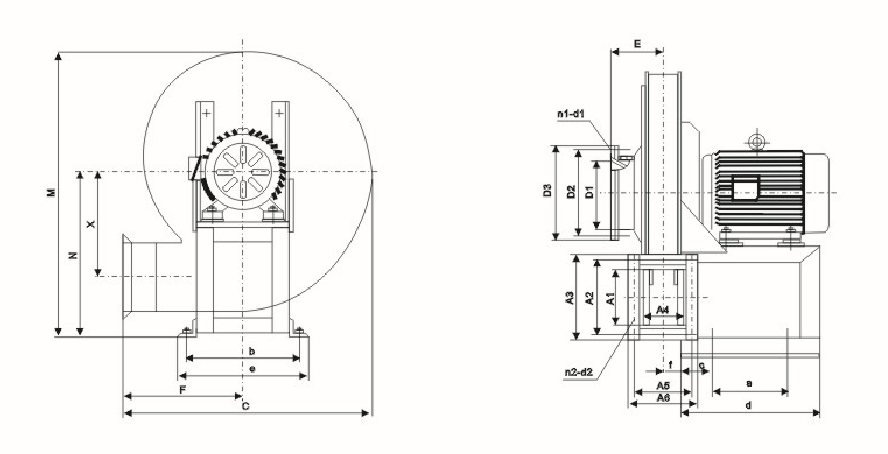

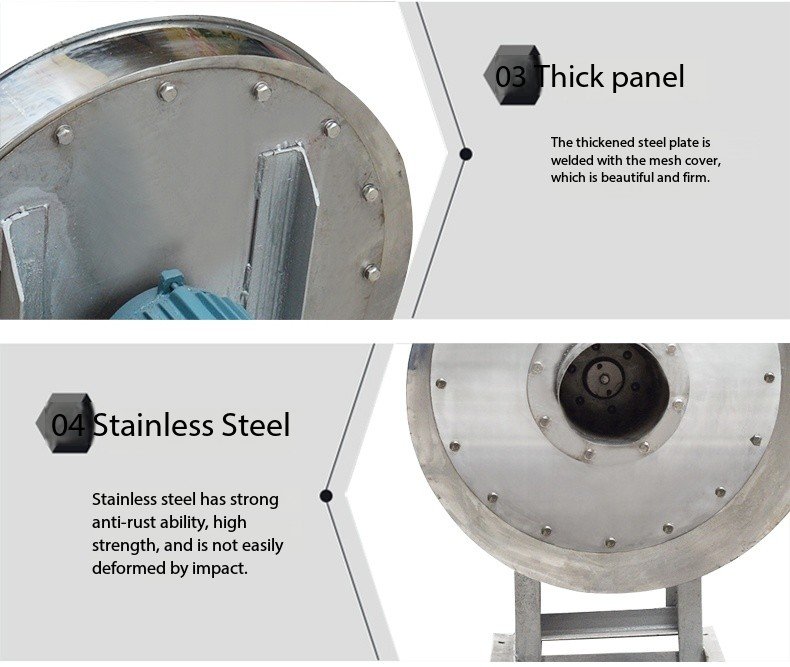

1)Structure

No3.15-6.3 is mainly composed of impeller, casing, air inlet, bracket, etc .;

No7.1 ~ 16 is mainly composed of impeller, casing, air inlet, transmission group, etc.

Impeller: 9-19 fan blades are 12 pieces, and 9-26 fan blades are 16 pieces. Both are forward curved leaves. The maximum peripheral speed of the outer edge of the impeller diffuser does not exceed 140m / s. After the impeller is formed, it is corrected by static and dynamic balance, so the operation is stable. (The material is generally stainless steel, aluminum alloy can be customized).

Case: Welded with universal steel plate to form a snail shell as a whole.

Air intake: It is made into a convergent streamlined overall structure, which is fixed on the front cover with bolts.

Transmission group: Composed of main shaft, bearing box, coupling, etc. Mainly made of high-quality steel, the overall structure of the bearing box, using rolling bearings, lubricated with bearing grease.

Supporting motor: Common type is equipped with Y series common motor, and explosion-proof type is equipped with YB2 series explosion-proof motor.

2)Type

This ventilator is a single suction type, with No3.15, 3.55,4, 4.5, 5.6, 6.3,7.1, 8, 9, 10, 11.2, 12.5, 14, 16,a total of 13 machine numbers.

The fan can be made into two types, right-handed and left-handed. From the end of the motor, if the impeller rotates clockwise, it is called right-handed fan, which is indicated by “right”; counterclockwise rotation is called left-handed fan, which is indicated by “left”.

The outlet position of the fan is expressed by the outlet angle of the casing. “Left” and “Right” can be made into six angles: 0 °, 45 °, 90 °, 135 °, 180 ° and 225 °.

The driving mode of the fan is A type (No3.15 ~ 6.3) and D type (No7.1~16).

(The impeller form and installation angle must be specified when ordering. If not specified, the default is right-handed and the angle is 180 °.)

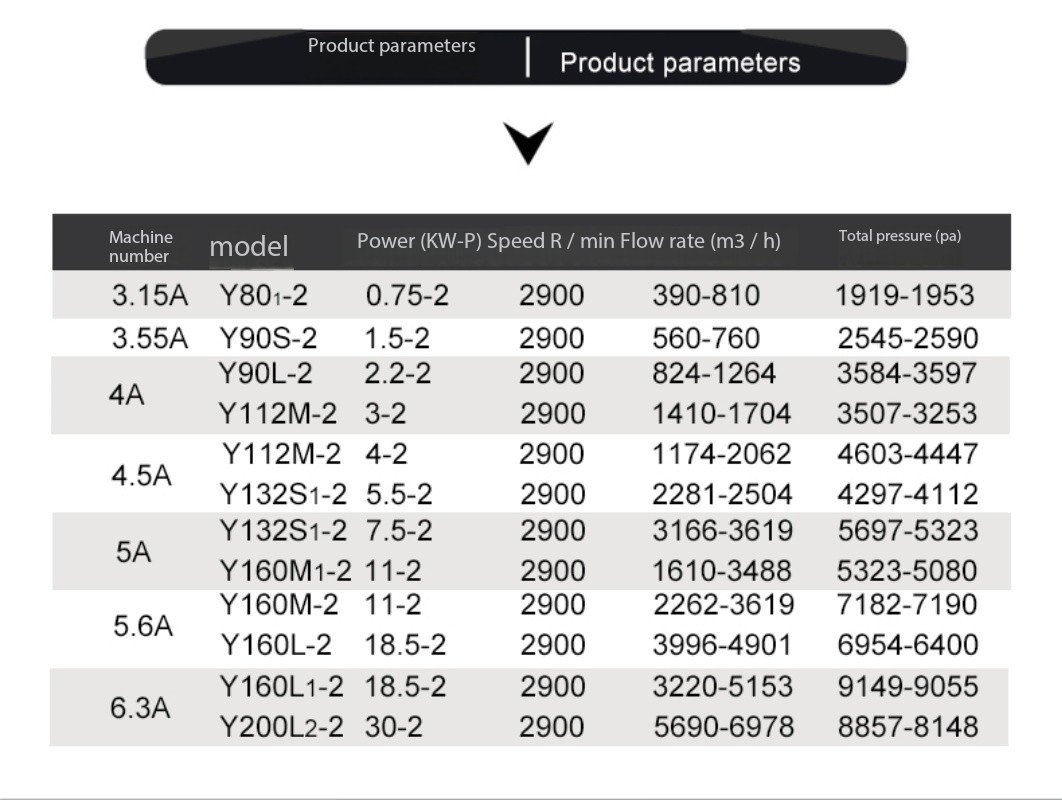

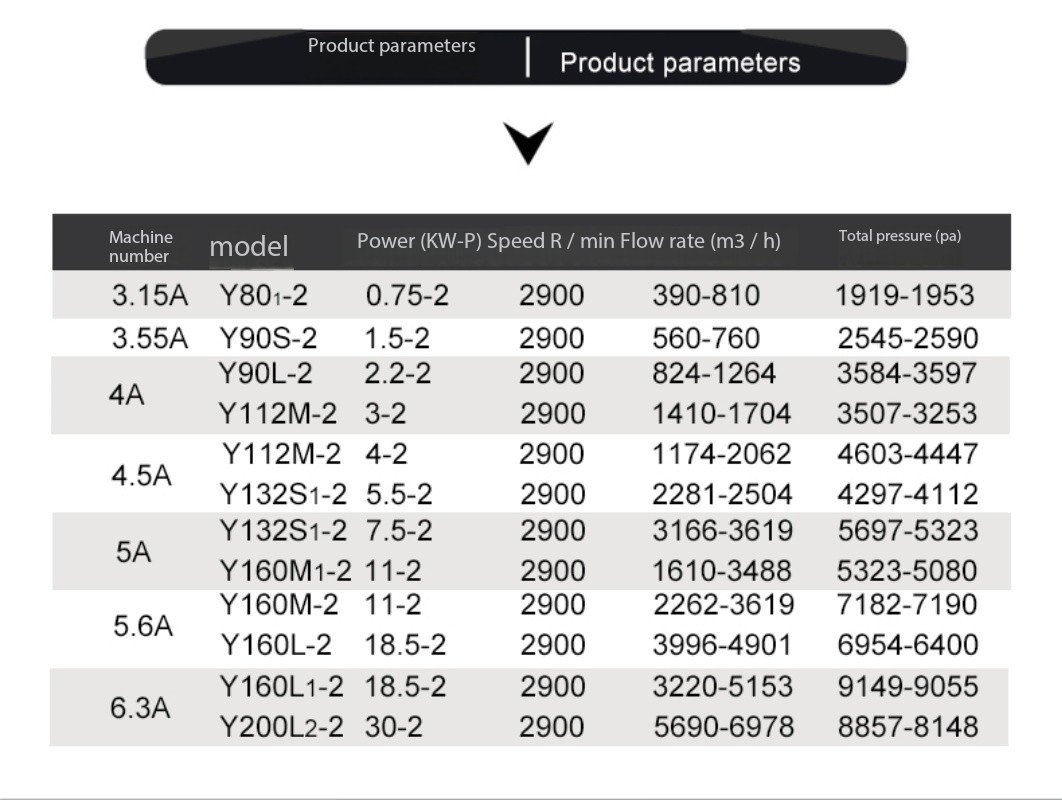

Parameters

Tech parameters of 9-19

| Model | Blade diameter (mm) | Power(kw) | Air volume (m ³/ h) | Wind pressure (Pa) | Speed (r/min) |

| 3.15A | 315 | 0.75 | 390-810 | 1919-1953 | 2900 |

| 1.1 | 600-810 | 1926-1754 | 2900 | ||

| 3.55A | 355 | 1.5 | 560-760 | 2545-2590 | 2900 |

| 2.2 | 860-1160 | 2554-2310 | 2900 | ||

| 4A | 400 | 2.2 | 824-1264 | 3584-3597 | 2900 |

| 3 | 1410-1704 | 3507-3253 | 2900 | ||

| 4.5A | 450 | 4 | 1174-2062 | 4603-4447 | 2900 |

| 5.5 | 2281-2504 | 4297-4112 | 2900 | ||

| 5A | 500 | 7.5 | 1610-3166 | 5697-5323 | 2900 |

| 11 | 1610-3488 | 5697-5080 | 2900 | ||

| 5.6A | 560 | 11 | 2262-3619 | 7185-7109 | 2900 |

| 18.5 | 3996-4901 | 9149-9055 | 2900 | ||

| 6.3A | 630 | 18.5 | 3220-5153 | 9049-9055 | 2900 |

| 30 | 5690-6978 | 8857-8148 | 2900 |

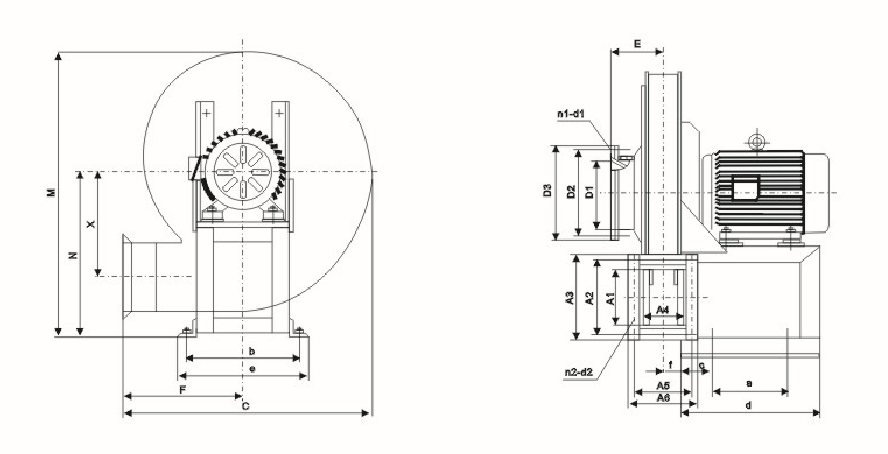

| No. | D1 | D2 | D3 | n1-d1 | A1 | A2 | A3 | A4 | A5 | A6 | X | Y | n2-d2 |

| 4A | Φ180 | Φ220 | Φ250 | 8-Φ7 | 128 | 174 | 214 | 92 | 138 | 178 | 3 | 2 | 10-Φ7 |

| 4.5A | Φ200 | Φ250 | Φ280 | 8-Φ7 | 144 | 198 | 230 | 104 | 152 | 192 | 3 | 2 | 10-Φ7 |

| 5A | Φ224 | Φ265 | Φ305 | 8-Φ7 | 160 | 206 | 246 | 115 | 160 | 202 | 3 | 2 | 10-Φ7 |

| 5.6A | Φ250 | Φ308 | Φ348 | 8-Φ10 | 179 | 225 | 265 | 129 | 174 | 215 | 3 | 2 | 10-Φ7 |

| 6.3A | Φ280 | Φ335 | Φ375 | 8-Φ10 | 202 | 288 | 288 | 145 | 189 | 231 | 3 | 2 | 10-Φ7 |

| No. | E | F | G | K | M | N | a | b | c | d | e | f |

| 4A | 108 | 361 | 682 | 286 | 715 | 420 | 200 | 350 | 50 | 300 | 385 | 35 |

| 4.5A | 120 | 344 | 716 | 322 | 782 | 450 | 240 | 390 | 50 | 340 | 430 | 39 |

| 5A | 126 | 376 | 188 | 258 | 868 | 500 | 340 | 450 | 50 | 440 | 495 | 43 |

| 5.6A | 140 | 415 | 874 | 401 | 962 | 550 | 350 | 480 | 50 | 450 | 534 | 48 |

| 6.3A | 157 | 461 | 975 | 451 | 1085 | 620 | 450 | 570 | 50 | 570 | 626 | 55 |

Product images

Request a Quote Now

Our team will get back to you within 24 hours.