What Is Stalling in Axial Fans

Stalling in axial fans occurs when airflow is reduced, causing instability and decreased performance.

Read More

Axial fans come in several types, each designed for specific applications. The main types include propeller fans for high airflow at low pressures, tubeaxial fans for improved performance in enclosed spaces, and vaneaxial fans for higher efficiency and pressure capabilities.

Specialized types such as high-temperature fans and variable pitch fans cater to extreme environments and adjustable airflow needs, respectively.

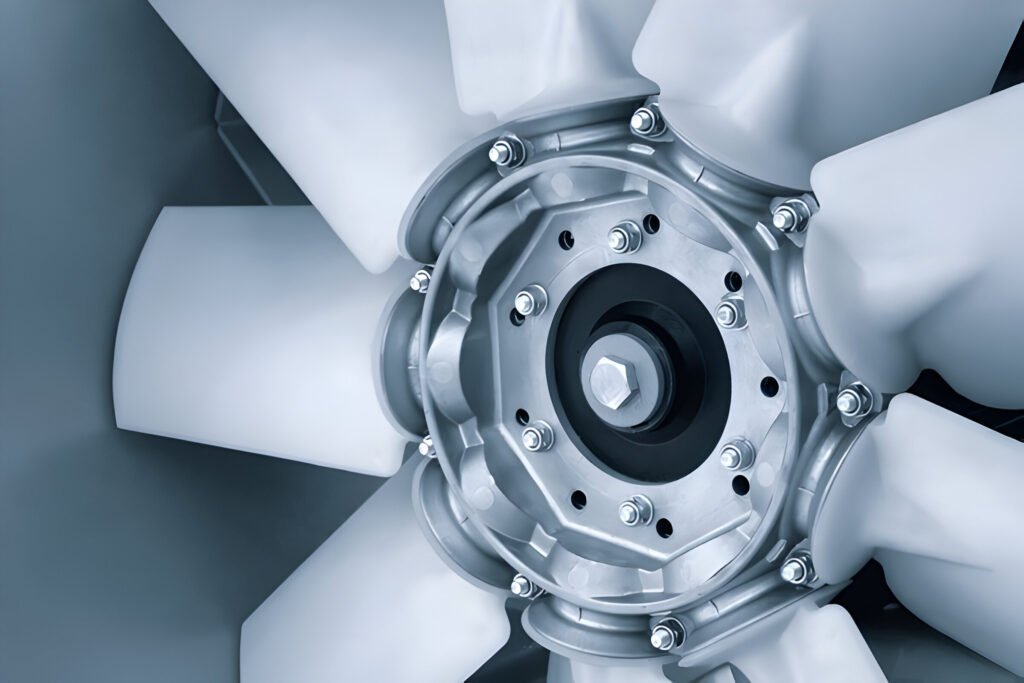

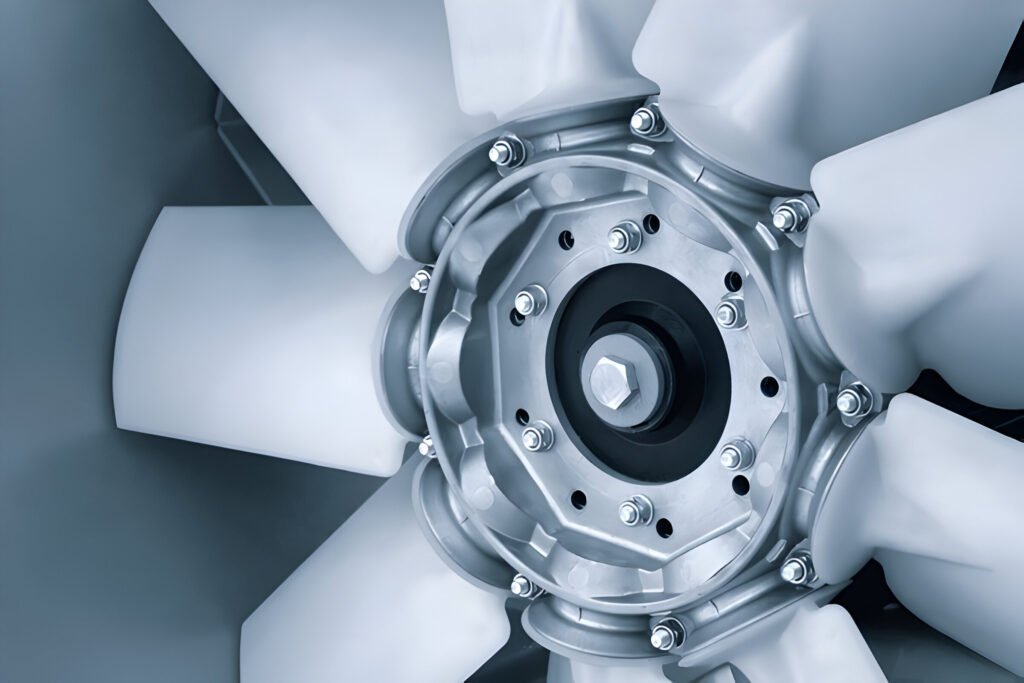

Axial fans move air parallel to their rotating shaft, efficiently handling large volumes in various cooling and ventilation systems. These cylindrical devices feature propeller-like blades attached to a hub driven by a motor. The spinning blades create a pressure difference, forcing air movement in the desired direction.

Propeller fans deliver high airflow at low pressures, making them the simplest axial fan type. They consist of a propeller-shaped blade attached to a motor, rotating to move air directionally.

These fans excel in moving large air volumes quickly, ideal for spaces requiring rapid air circulation or cooling, such as warehouses, factories, and greenhouses. Wall or ceiling mounting maximizes their effectiveness.

Key advantages include low initial cost and easy installation. Propeller fans operate quietly compared to other fan types, suiting noise-sensitive environments. However, they lack effectiveness in high-pressure or precise airflow control applications.

Tubeaxial fans enclose propeller blades within a cylindrical housing, directing airflow and reducing turbulence. This design increases pressure capabilities, making them suitable for HVAC systems, industrial ventilation, and cooling towers. The cylindrical housing enables better air movement control, ideal for ducted systems.

These fans operate at higher speeds than propeller fans, delivering increased air volume and pressure.

Vaneaxial fans incorporate guide vanes before or after the impeller, straightening airflow and reducing turbulence. This design increases efficiency and offers higher pressure capabilities compared to other axial fan types. Vaneaxial fans excel in applications requiring both high airflow and pressure.

The compact design of vaneaxial fans allows for shorter installations than tubeaxial fans. Common applications include HVAC systems, industrial processes, and ventilation in space-limited environments. Guide vanes contribute to noise reduction, making vaneaxial fans quieter in many scenarios.

High-temperature axial fans operate in extreme heat environments, often exceeding 1000°F (538°C). Their construction uses specialized materials to maintain structural integrity and performance in intense heat.

Variable pitch axial fans offer versatility across applications. These fans feature adjustable blades that rotate to change the angle of attack, modifying airflow and pressure without altering speed.

Low noise axial fans reduce sound output while maintaining efficient airflow. These fans incorporate features to minimize noise levels for quiet environments.

Specialized blade designs optimize shapes and angles, reducing turbulence and air resistance. This results in smoother airflow and decreased noise. Advanced materials absorb vibrations and dampen sound.

Mixed flow fans combine axial and centrifugal fan characteristics, offering a solution for specific airflow needs. They handle higher pressures than axial fans while maintaining a compact size. These fans suit applications with limited space and high-performance requirements.

Air enters axially and exits at an angle between axial and radial directions in mixed flow fans. This design enables higher pressure capabilities without sacrificing flow rate. The impeller blades are curved and angled to redirect airflow efficiently.

Axial fan selection requires evaluating airflow volume, pressure, and space constraints.

Choose fans with high efficiency ratings, measured in cubic feet per minute (CFM) per watt. Efficient fans reduce operating costs over time.

Specific power consumption, measured in watts per CFM, indicates efficiency. Lower values signify better performance.

Check fan sound power level (decibels) against application’s acceptable noise threshold. Noise reduction often decreases efficiency. Balance noise requirements with performance needs.

Temperature, corrosion, and moisture influence axial fan selection. Consider these environmental factors when choosing a fan for your application.

Axial fan reliability and maintenance directly impact performance, longevity, and operational costs.

Axial fan selection requires evaluating total ownership cost over its lifetime. This includes energy consumption, maintenance, and replacement expenses.

Axial fans typically last 5-10 years before replacement.

Axial fans for hazardous environments require specialized design. Explosion-proof or ATEX-certified models incorporate spark-resistant materials and sealed enclosures to prevent ignition in potentially explosive atmospheres.

Energy-efficient axial fans utilize advanced blade designs and high-efficiency motors. Models with variable speed controls and Energy Star certification offer optimal energy savings. These fans are often marketed as eco-friendly or green options.

Axial fans require annual servicing and monthly checks for abnormal sounds or vibrations.