A Comprehensive Guide to Axial Fans

Discover the ins and outs of axial fans with our comprehensive guide, covering types, applications, and selection criteria.

Read More

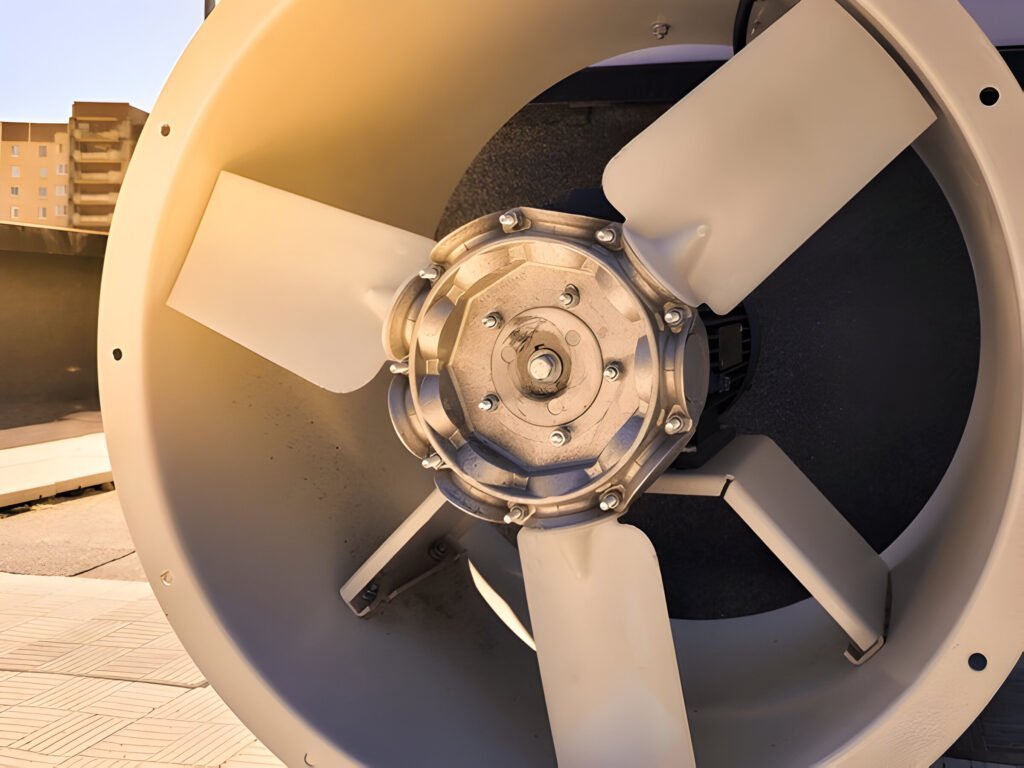

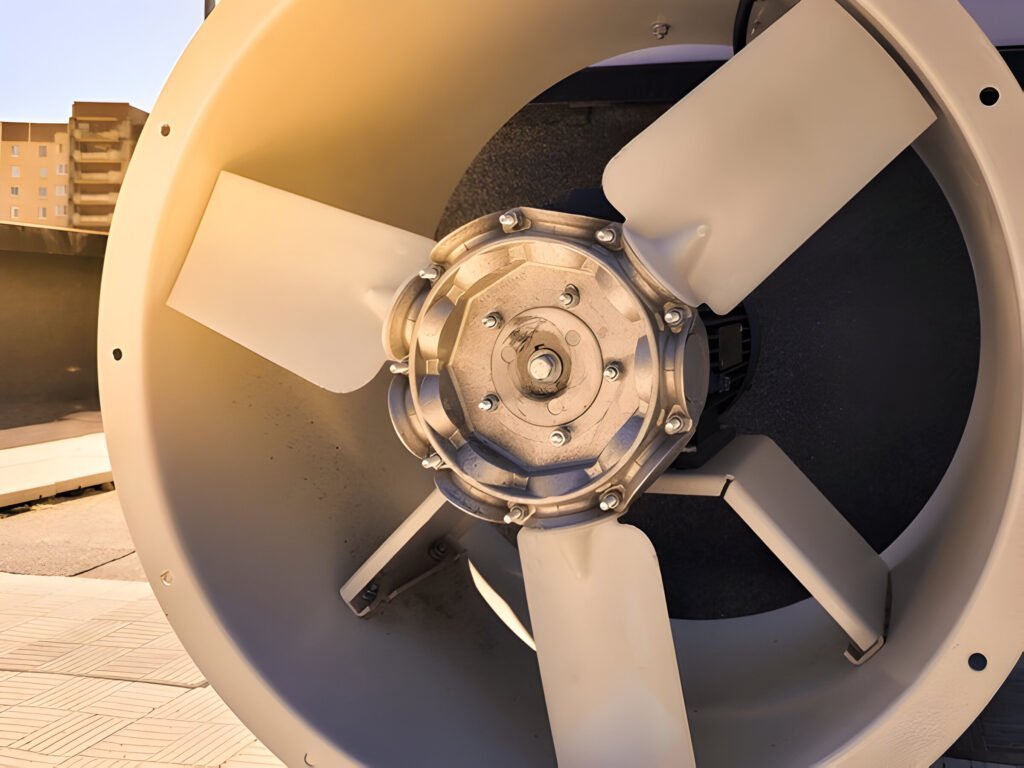

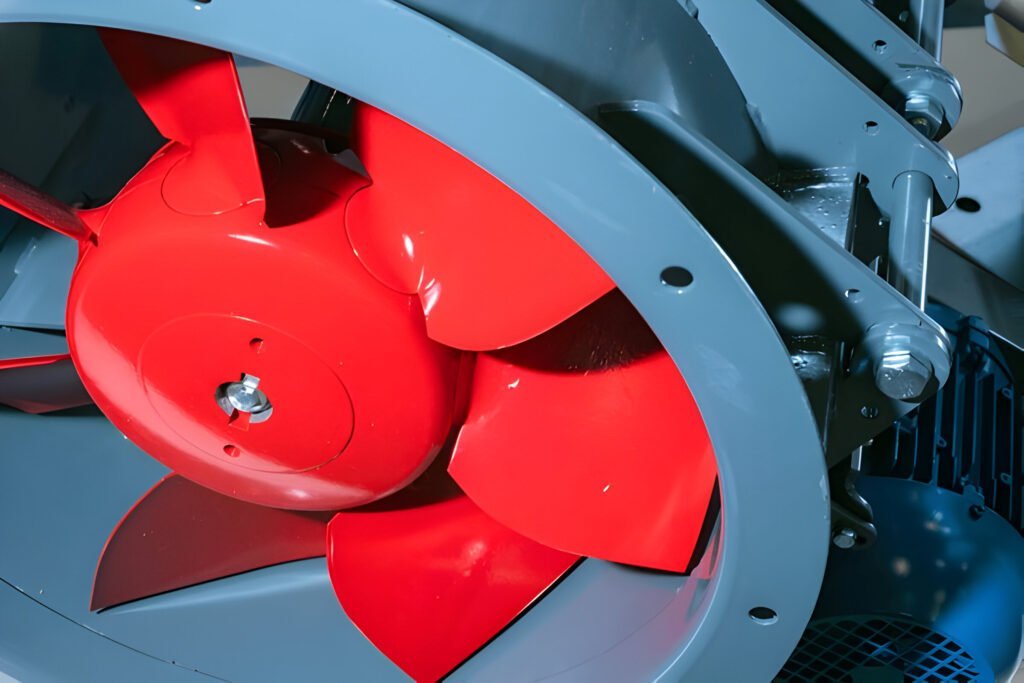

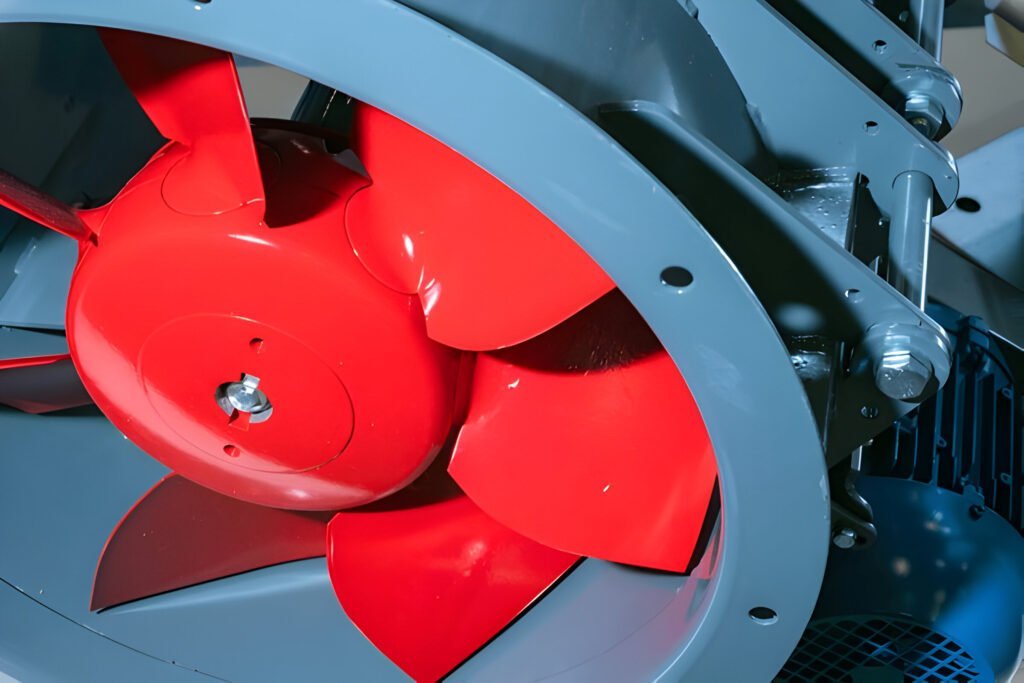

Axial fans are a type of air-moving device that propels air along the axis of the fan’s rotation. These fans consist of a circular arrangement of blades mounted on a hub, which is connected to a motor shaft. When the motor spins the hub, the blades force air to move parallel to the shaft, creating a high-volume, low-pressure airflow. This design makes axial fans ideal for applications that require large amounts of air to be moved through a system with minimal resistance, such as in ventilation, cooling, and exhaust systems.

The blades of an axial fan are typically designed with an airfoil cross-section, which helps to optimize airflow efficiency and reduce noise. The number of blades, their pitch, and the overall diameter of the fan determine its performance characteristics, including the volume of air moved (measured in cubic feet per minute or CFM) and the pressure differential created (measured in inches of water gauge or in.wg).

Axial fans operate on fluid dynamics principles. The motor-driven blades create a pressure differential between the fan’s front and back. This forces air to move from high to low-pressure areas, generating airflow parallel to the rotation axis.

Blade design critically affects fan efficiency. Each blade’s airfoil shape, similar to an airplane wing, creates lift during rotation, propelling air in the desired direction. The blade pitch balances airflow and pressure. Steeper pitches move more air but require higher power input, while shallower pitches offer energy efficiency at the cost of reduced air movement.

Axial fan impellers or blades move air in the desired direction. Curved or airfoil-shaped blades maximize air movement while reducing noise and energy consumption. Axial fans generally feature three to eight blades.

The hub serves as the central component of an axial fan, connecting blades to the motor shaft and providing structural support.

Industrial settings often utilize larger hubs to accommodate more blades, while household fans typically feature smaller hubs.

The shaft forms the axial fan’s core, extending from motor to hub. It transmits rotational power to the fan blades.

Electric motors power axial fan rotation, converting electrical energy into mechanical energy.

Axial fan casings enclose and protect internal components while directing airflow. Made from metal or high-strength plastic, these structures shield working parts from external damage and contaminants. The casing’s shape minimizes turbulence and optimizes air movement.

Axial fans excel in airflow efficiency, moving large air volumes with minimal power consumption. Their design allows air to flow parallel to the rotation axis, optimizing blade shape for effective pressure differentials. This configuration enables high flow rates, particularly suitable for open spaces and low static pressure systems.

Axial fans feature a compact and simple design, consisting of a hub with attached blades rotating within a cylindrical casing. This straightforward construction facilitates easy installation and maintenance, particularly in tight spaces where other fan types cannot fit. Common applications include computer systems, automotive cooling, and HVAC units.

Axial fans excel in energy efficiency due to their simple design. They consume less power than other fan types, making them ideal for long-term operation. The streamlined airflow path reduces energy loss, enhancing performance with lower input. Many axial fans now incorporate EC (electronically commutated) motors, further improving efficiency.

Axial fans often operate at low noise levels, making them suitable for sound-sensitive environments like offices, hospitals, and residential areas.

Low-noise axial fans typically produce sound levels between 20 and 40 decibels (dB), comparable to a whisper or quiet library.

Propeller fans feature a propeller-like blade assembly mounted on a central hub, rotating to move air in the axial direction. They find applications in household cooling and industrial ventilation systems.

High air flow rates and low pressure capabilities distinguish propeller fans. They excel in moving large volumes of air against minimal resistance, making them suitable for open spaces or areas with limited ductwork.

Propeller fans have limitations. They perform poorly in systems with high static pressure and lack precise airflow control capabilities.

Tube-axial fans incorporate a cylindrical housing encasing the fan blades, focusing airflow for applications requiring higher pressure. These fans suit ventilation systems and industrial processes, offering improved efficiency over propeller fans.

The housing reduces noise and directs airflow, making tube-axial fans optimal for ducted systems. Common applications include HVAC, cooling towers, and industrial exhaust systems. Tube-axial fans handle static pressures from 0.5 to 3.5 inches of water gauge, surpassing propeller fan capabilities.

Tube-axial fans excel in balancing airflow and pressure requirements. They perform efficiently in confined spaces and integrate seamlessly into existing ductwork or ventilation systems.

Vane-axial fans represent an advanced iteration within the axial fan family. These fans incorporate guide vanes positioned before, after, or on both sides of the impeller. The vanes straighten airflow, reducing turbulence and enhancing efficiency. Vane-axial fans deliver higher pressures and improved performance compared to tube-axial models.

Applications requiring precise airflow control benefit from vane-axial fans. HVAC systems, industrial processes, and aircraft engines frequently utilize these fans. Their compact design handles higher static pressures effectively. The guide vanes contribute to noise reduction, making vane-axial fans suitable for sound-sensitive environments.

Pressure optimization focuses on blade angle and pitch. Steeper angles increase pressure but may reduce efficiency. Variable pitch blades offer adaptability to changing conditions. Well-designed casing improves overall performance. Advanced features like swept blades or winglets enhance efficiency and reduce noise.

Blade count affects air movement and noise generation. Fewer blades typically produce less noise but may sacrifice efficiency. More blades can increase efficiency but potentially generate more noise. Optimal blade count depends on specific application requirements.

Blade shape influences airflow patterns and efficiency. Airfoil-shaped blades often provide better performance than flat blades. Blade tip design affects noise generation and efficiency. Winglets or other tip modifications can reduce vortex formation and improve overall performance.

Hub-to-tip ratio optimization balances structural integrity and airflow capacity. A larger hub provides stability but reduces the effective blade area. A smaller hub increases blade area but may compromise structural integrity.

Rotational speed affects air movement and noise generation. Higher speeds generally produce more airflow but increase noise levels. Lower speeds reduce noise but may sacrifice performance.

Casing design influences airflow patterns and overall efficiency. A properly designed inlet reduces turbulence and improves air entry. Outlet design affects air distribution and pressure recovery. Streamlined internal surfaces minimize energy losses due to friction.

Rotating fan blades create a slipstream, which is air moving in the same direction as the blades. This slipstream impacts fan efficiency and overall performance.

As air passes through the fan, it gains rotational energy, resulting in swirl. Swirl can decrease the fan’s ability to generate linear airflow.

Guide vanes or stators can redirect airflow and reduce swirl. Optimized blade profiles minimize energy loss due to slipstream effects.

Blade Element Theory divides fan blades into small sections for detailed analysis of aerodynamic forces. This approach examines angle of attack, lift, and drag at different radial positions on each blade element. By integrating the contributions of all elements, it predicts overall fan performance.

Axial fans experience stalling when airflow separates from the blade surface. This phenomenon causes a sudden drop in performance, reducing airflow and pressure while increasing noise and vibration. Stalling occurs when the angle of attack between the blade and incoming air becomes too steep.

Several factors trigger stall in axial fans:

Surging in axial fans differs from stalling, characterized by cyclical airflow and pressure fluctuations. This phenomenon manifests as rapid performance changes, often accompanied by loud noises and vibrations. The instability occurs when the fan fails to maintain steady flow, causing air to pulse back and forth through the system.

Low flow rates or high pressures typically trigger surging. System resistance changes, inlet flow distortions, or mismatched fan and system characteristics can initiate this effect. In multiple parallel fan setups, surging in one unit can quickly spread to others.

Axial fans efficiently cool and ventilate large spaces. These fans operate in industrial facilities, commercial buildings, warehouses, factories, and data centers to combat heat buildup. Their ability to move large air volumes quickly maintains comfortable temperatures and air quality.

Axial fans excel in general air circulation applications beyond cooling and ventilation. Large warehouses use them to distribute air evenly, preventing stagnant pockets and maintaining consistent temperatures. Greenhouses employ these fans to simulate natural airflow, promoting plant growth and reducing humidity.

Axial fans serve critical functions in exhaust and extraction systems across industrial and commercial environments. These fans remove harmful fumes, dust, and excess heat from large spaces like factories, warehouses, and underground parking garages.

Centrifugal and axial fans differ significantly in airflow direction and pressure capabilities. Centrifugal fans move air radially, creating higher pressure but lower flow rates. Axial fans push air parallel to the shaft, generating higher flow rates at lower pressures.

Axial fans excel in high-flow, low-pressure applications. They provide efficient ventilation and cooling for large spaces like warehouses, factories, and data centers. Their design allows for greater air movement with less energy consumption compared to centrifugal fans.

Noise levels and efficiency vary between the two fan types. Axial fans operate more quietly, especially at higher flow rates. They also demonstrate superior efficiency in moving large volumes of air. This makes them preferable in noise-sensitive environments or where energy conservation is a priority.

Cost and maintenance considerations favor axial fans in many scenarios. Their compact design reduces installation costs and space requirements. Axial fans have fewer moving parts, leading to lower maintenance needs and potentially longer operational lifespans.

Centrifugal fans remain advantageous in specific applications. They handle particulate-laden air more effectively and generate higher pressures. This makes them suitable for industrial processes requiring dust extraction or high-pressure air movement.

igh airflow fans suit large volume air movement requirements. High-pressure fans perform better in systems with significant resistance.

Higher CFM ratings indicate greater air movement capacity, while higher pressure ratings suggest better performance against system resistance. Efficient fans minimize power consumption while maximizing air output.

Space constraints dictate axial fan selection. Measure available dimensions, including fan diameter, depth, and mounting requirements. Consider airflow clearance around the fan.

Installation factors encompass mounting options: panel-mounted, flange-mounted, or tube-axial configurations. Fan orientation affects performance in specific positions. Evaluate maintenance and cleaning access. Assess power source and control system connections. Ensure compatibility with existing ductwork or ventilation systems.

Axial fan selection requires balancing cost and quality factors. Initial purchase price impacts budgets, but long-term operational costs often outweigh upfront expenses.

No, standard axial fans are not explosion proof. Explosion proof axial fans are specially designed and certified to operate safely in hazardous environments with flammable gases, vapors, or dust. These fans have features such as non-sparking construction, properly rated enclosures, and temperature limiting devices to prevent ignition of the surrounding atmosphere. Standard axial fans lack these critical safety features.

The fan will spin in the opposite direction. This reverses the airflow, potentially reducing cooling efficiency. The fan may also experience increased stress and wear, leading to a shorter lifespan. In some cases, reversed wiring can cause the fan to stall or overheat.