Cross flow fans and centrifugal fans are two distinct types of air-moving devices commonly used in industrial, commercial, and residential applications. While both serve the purpose of circulating air, they differ significantly in their design, operating principles, and performance characteristics.

This blog post will delve into the key differences between cross flow fans and centrifugal fans, examining their unique features, energy consumption, noise levels, and typical applications.

What Is Cross Flow Fan

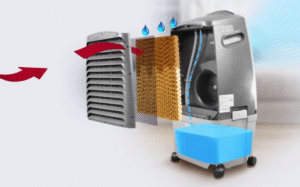

A cross flow fan, also known as a tangential or transverse fan, is a type of fan that moves air in a direction perpendicular to the fan’s intake. This unique airflow pattern distinguishes cross flow fans from other types of fans, such as axial fans and centrifugal fans. Cross flow fans feature a cylindrical impeller with forward-curved blades arranged in a circular shape, which allows for a wide and uniform distribution of airflow across the entire width of the fan. This design makes cross flow fans ideal for applications requiring a broad, constant stream of low-pressure air, such as air curtains, cooling electronic components, and ventilation in confined spaces.

How Cross Flow Fans Work

Cross flow fans operate by drawing air in through the side of the fan parallel to the shaft, then accelerating and discharging it perpendicular to the intake direction. As the impeller rotates, the blades generate a stable vortex that continuously draws in and expels air. This vortex, also called a vortex tongue, is created by the unique shape and arrangement of the blades, which allows the air to flow smoothly and efficiently through the fan.

What Is Centrifugal Fan

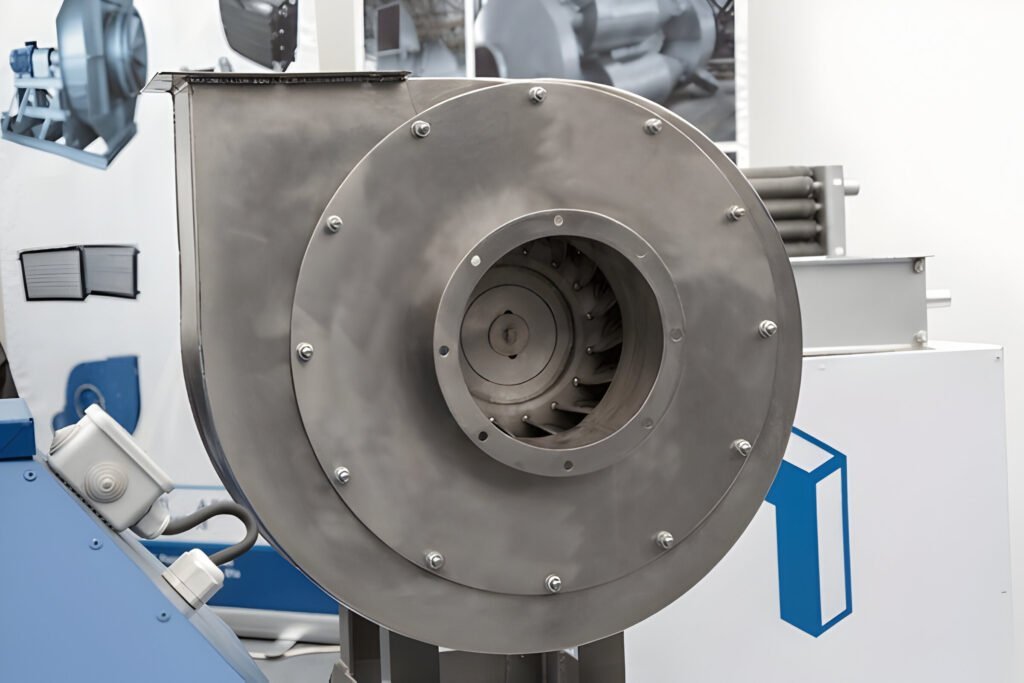

A centrifugal fan, also known as a radial fan or blower, is a type of fan that utilizes centrifugal force to generate airflow. Unlike cross flow fans, which move air in a straight line, centrifugal fans use a rotating impeller to draw air into the center of the fan and then expel it radially outward, perpendicular to the shaft. This design allows centrifugal fans to generate higher pressures and operate more efficiently in applications requiring greater static pressure.

How Centrifugal Fans Work

The working principle of a centrifugal fan relies on the conversion of rotational kinetic energy into increased static pressure. As the impeller rotates, it draws air into the center of the fan through an inlet. The spinning motion of the blades then accelerates the air radially outward, creating a centrifugal force that increases the air velocity and pressure.

Key Difference Between Cross Flow Fan and Centrifugal Fan

Cross flow fans and centrifugal fans are two distinct types of fans with significant differences in their design features, performance characteristics, energy consumption, and noise levels.

Design Features

The primary design difference between cross flow fans and centrifugal fans lies in their blade configuration and airflow direction. Cross flow fans, also known as tangential fans, feature an elongated impeller with numerous blades arranged parallel to the fan’s axis. This unique design allows air to flow through the fan in a straight line, perpendicular to the axis of rotation.

Centrifugal fans have a circular impeller with blades that curve either forward or backward. The impeller is mounted on a central shaft, and as it rotates, air is drawn in axially and discharged radially, perpendicular to the intake direction.

Pressure Vs. Airflow

Cross flow fans generate a wide, uniform airflow across their length, making them ideal for applications requiring a broad, gentle flow of air. They typically operate at lower pressures compared to centrifugal fans and are well-suited for low-pressure, high-volume airflow applications.

Centrifugal fans are capable of producing higher pressures and are designed to handle more demanding airflow requirements. They can generate high-pressure airflows and are commonly used in applications where the air must be moved against resistance or through a ducted system.

Energy Consumption

Cross flow fans generally have lower power consumption compared to centrifugal fans of similar size and airflow capacity. This is due to their simple design and the fact that they operate at lower pressures. Cross flow fans are often more energy-efficient in applications where high volumes of air need to be moved with minimal resistance.

Centrifugal fans, while capable of delivering higher pressures, may consume more energy to overcome the resistance in the system.

Noise Levels

Cross flow fans typically generate lower noise levels compared to centrifugal fans. The elongated design of cross flow fans allows for a more gradual and smooth airflow, resulting in reduced turbulence and noise. The airflow through a cross flow fan is laminar, which contributes to its quiet operation.

Centrifugal fans can produce higher noise levels due to the high-velocity airflow and turbulence generated by the impeller.

Applications

Typical Uses for Cross Flow Fans

- Air curtains for entrances in commercial buildings, providing a barrier between inside and outside air

- Cooling electronic components in devices like computers, televisions, and audio equipment

- Air conditioning units for residential and commercial spaces, particularly where space is limited

- Ventilation systems in vehicles, such as buses and trains, to circulate air efficiently

- Drying systems for industrial processes, such as food production or textile manufacturing

- Air purifiers and filtration systems to remove contaminants and improve indoor air quality

- Refrigeration units, including display cases and vending machines, to maintain consistent temperatures

- Heating equipment, such as space heaters and heat pumps, to distribute warm air effectively

Typical Uses for Centrifugal Fans

- HVAC systems in residential, commercial, and industrial buildings for ventilation and temperature control

- Exhaust systems for removing fumes, dust, or other contaminants from indoor spaces

- Industrial processes that require the movement of large volumes of air, such as drying or cooling

- Pneumatic conveying systems for transporting materials like grains, powders, or pellets

- Combustion air supply for boilers, furnaces, and other fuel-burning equipment

- Dust collection systems in woodworking shops, factories, and other industrial settings

- Fume extraction in laboratories, chemical plants, and other facilities with potentially hazardous airborne substances

Advantages and Disadvantages

Cross Flow Fans

Advantages:

- Compact design, making them suitable for applications with limited space

- Ability to produce a wide, uniform airflow pattern across the length of the fan

- Relatively quiet operation compared to other fan types, ideal for noise-sensitive environments

- Energy-efficient, particularly at low to medium airflow rates and static pressures

- Versatile mounting options, allowing for installation in various orientations

Disadvantages:

- Lower maximum airflow and static pressure compared to centrifugal fans of similar size

- Less efficient at higher airflow rates and static pressures

- More complex design and manufacturing process, potentially leading to higher costs

- Reduced performance in high-temperature or corrosive environments due to material limitations

Centrifugal Fans

Advantages:

- High airflow rates and static pressures, suitable for applications with demanding performance requirements

- Ability to handle high-temperature and corrosive environments with appropriate material selection

- Efficient operation at higher airflow rates and static pressures compared to cross flow fans

- Relatively simple design and manufacturing process, potentially resulting in lower costs

- Wide range of sizes and configurations available to suit various application needs

Disadvantages:

- Larger size compared to cross flow fans, requiring more space for installation

- Noisier operation, particularly at high airflow rates and static pressures

- Less uniform airflow pattern, with higher velocities near the outlet and lower velocities at the periphery

- Higher power consumption, especially at lower airflow rates and static pressures

- Limited mounting options due to the need for a stable base to support the fan’s weight and vibration.