In the realm of machinery and automotive engineering, cooling systems play a crucial role in ensuring optimal performance and longevity of engines. Two common types of cooling fans employed in these systems are electric fans and clutch fans, each with their unique characteristics and advantages.

This blog post will delve into the key differences between electric fans and clutch fans, examining their power source, efficiency, performance metrics, as well as noise and vibration levels.

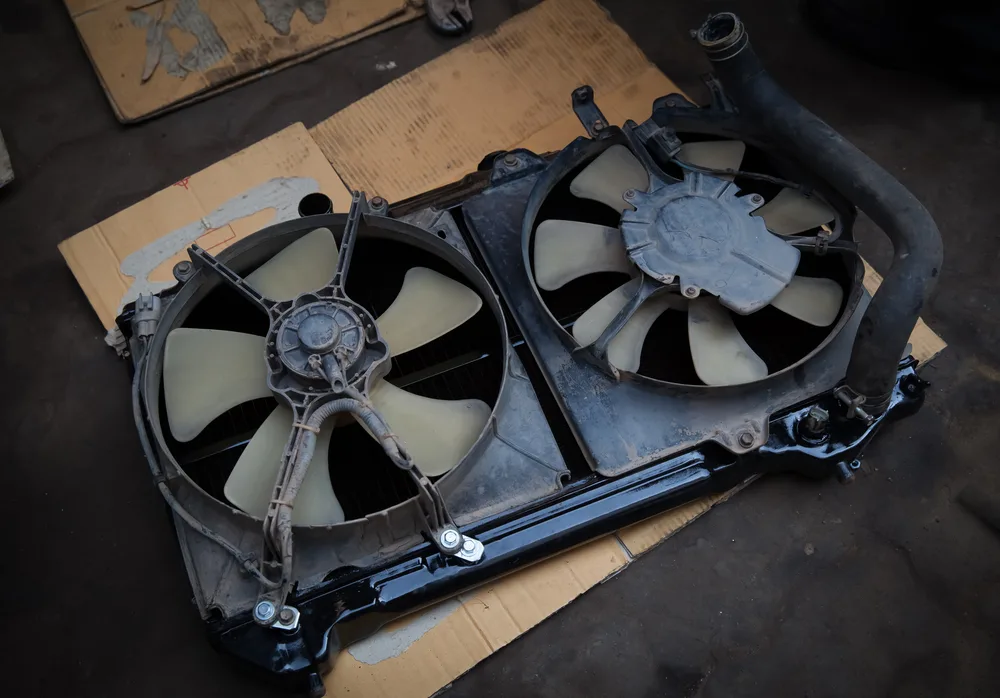

What Is a Clutch Fan

A clutch fan, also known as a mechanical fan clutch or thermal clutch fan, is a temperature-controlled cooling device used in vehicle engines. It is mounted on the water pump shaft and driven by the engine’s mechanical energy. The clutch fan consists of a fan blade assembly connected to a clutch mechanism that engages and disengages based on the engine temperature.

When the engine is cold or operating at low temperatures, the clutch remains disengaged, allowing the fan to spin freely at a lower speed than the water pump. As the engine temperature rises, the thermal clutch begins to engage, gradually increasing the fan speed until it matches the speed of the water pump at higher engine temperatures. This variable engagement allows the clutch fan to provide cooling as needed while minimizing parasitic power loss when cooling demands are low.

Advantages of Clutch Fans

- Temperature-sensitive operation: Clutch fans engage and disengage based on engine temperature, providing cooling only when necessary.

- Reduced parasitic power loss: When disengaged, clutch fans minimize the power drawn from the engine, improving overall engine efficiency.

- Simplicity and reliability: Clutch fans have a simple mechanical design and are generally reliable, requiring minimal maintenance.

- Cost-effective: Compared to electric fans, clutch fans are typically less expensive to manufacture and install.

- Compatibility: Clutch fans are commonly used in older vehicles and are compatible with most factory radiator shrouds.

Disadvantages of Clutch Fans

- Limited control: Clutch fans rely on engine temperature and cannot be easily controlled or adjusted for specific cooling requirements.

- Noise and vibration: When fully engaged, clutch fans can generate significant noise and vibration, especially at high engine speeds.

- Packaging constraints: Clutch fans require sufficient space in the engine compartment, which can be a challenge in modern, compact engine bays.

- Reduced efficiency at low speeds: At low engine speeds or in stop-and-go traffic, clutch fans may not provide adequate cooling, as they depend on engine RPM.

- Potential for failure: Over time, the clutch mechanism can wear out or fail, leading to reduced cooling performance or complete fan disengagement.

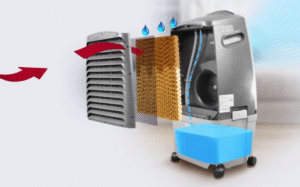

What Is an Electric Fan

An electric fan is a type of cooling device that uses an electric motor to power a fan blade, which circulates air to provide cooling for an engine. Unlike a clutch fan, which is mechanically driven by the engine’s water pump or crankshaft, an electric fan operates independently and is controlled by a thermostat or the engine control module (ECM).

Electric fans typically consist of an electric motor, fan blade, and shroud. The motor is powered by the vehicle’s electrical system and can be turned on and off as needed to regulate engine temperature. The fan blade is designed to move a large volume of air through the radiator and engine compartment, while the shroud helps to direct the airflow and improve efficiency.

Advantages of Electric Fans

- Increased fuel economy: Electric fans only run when necessary, reducing parasitic power loss and improving overall fuel efficiency compared to constantly running mechanical fans.

- Improved engine performance: By operating independently of engine speed, electric fans can provide optimal cooling even at low RPMs or when the vehicle is stationary, ensuring consistent engine temperature and performance.

- Reduced noise and vibration: Electric fans are generally quieter than mechanical fans and produce less vibration, contributing to a more comfortable driving experience.

- Customizable control: Electric fans can be programmed to operate at different speeds or temperatures, allowing for more precise control over engine cooling.

- Compact design: Electric fans often have a slimmer profile than clutch fans, making them easier to package in tight engine compartments and allowing for better airflow.

Disadvantages of Electric Fans

- Higher initial cost: Electric fan systems can be more expensive to purchase and install compared to traditional clutch fans, especially if aftermarket wiring and controllers are required.

- Increased electrical load: The addition of an electric fan places an extra burden on the vehicle’s electrical system, potentially requiring upgrades to the alternator or wiring to accommodate the increased amperage draw.

- Potential for failure: Like any electrical component, electric fans can be subject to wear, damage, or failure over time, which may require costly repairs or replacements.

- Limited cooling at high speeds: In some cases, electric fans may not provide sufficient cooling during prolonged high-speed driving or extreme heat conditions, as they lack the additional airflow generated by a mechanical fan’s direct connection to the engine’s speed.

- Installation complexity: Retrofitting an electric fan system to an older vehicle or engine not originally designed for it can be challenging, often requiring custom mounting brackets, wiring, and modifications to the cooling system.

Key Difference Between Electric Fan and Clutch Fan

The primary differences between electric fans and clutch fans lie in their power source, efficiency, performance metrics, noise levels, and vibration.

Power Source and Efficiency

Clutch fans, also known as mechanical fan clutches, rely on the engine’s mechanical energy to operate. They are driven by a belt connected to the water pump or crankshaft pulley, which means their speed is directly proportional to the engine RPM. As a result, clutch fans can consume a significant amount of engine power, especially at higher speeds, leading to reduced fuel economy and overall engine efficiency.

Electric fans are powered by the vehicle’s electrical system, drawing energy from the alternator and battery. They operate independently of the engine speed and are controlled by a thermostat or the engine control unit (ECU). Electric fans only run when necessary, such as when the engine temperature reaches a certain threshold, making them more energy-efficient compared to clutch fans.

Performance Metrics

Clutch fans are generally more effective at moving large volumes of air through the engine compartment, particularly at lower engine speeds. They are well-suited for vehicles that frequently operate under heavy loads or in high-temperature conditions, such as work trucks or vehicles used for towing. However, as engine speed increases, the airflow generated by the clutch fan can become excessive, leading to increased drag on the engine and reduced efficiency.

Electric fans offer more precise control over airflow and can be optimized for specific engine temperature ranges. They can be programmed to run at different speeds based on the engine’s cooling requirements, ensuring optimal performance without wasting energy. Electric fans are particularly effective at maintaining stable engine temperatures during idle or low-speed driving conditions, where clutch fans may struggle to provide adequate airflow.

Noise and Vibration

Clutch fans are known for producing more noise and vibration compared to electric fans. The mechanical connection between the fan and the engine means that any imbalances or irregularities in the fan blade or clutch assembly can translate into noticeable vibrations and noise within the engine compartment. Additionally, as the fan speed increases with engine RPM, the noise level can become more pronounced, potentially impacting driver comfort.

Electric fans are generally quieter and produce less vibration. Since they are not mechanically linked to the engine, electric fans can be mounted on rubber isolators or other vibration-damping materials to minimize noise transmission. The ability to control fan speed independently also allows for quieter operation, especially during low-speed driving or when the engine is under moderate loads.

FAQs

What are the two types of fan clutch?

The two main types of fan clutches are thermal and non-thermal.

- Thermal fan clutches engage and disengage based on the temperature of the surrounding air, using a bimetallic strip or a temperature-sensitive fluid.

- Non-thermal fan clutches, also known as mechanical fan clutches, engage and disengage based on the engine’s RPM.

Do all cars have a fan clutch?

Not all cars have a fan clutch. Some vehicles, particularly older models or those with smaller engines, may have a fixed fan that runs continuously when the engine is on.