Axial Fan Vs Jet Fan: What Is the Difference

Axial fans move air parallel to shaft; jet fans propel air in focused streams. Axial fans are for ventilation, jet fans for thrust.

Read More

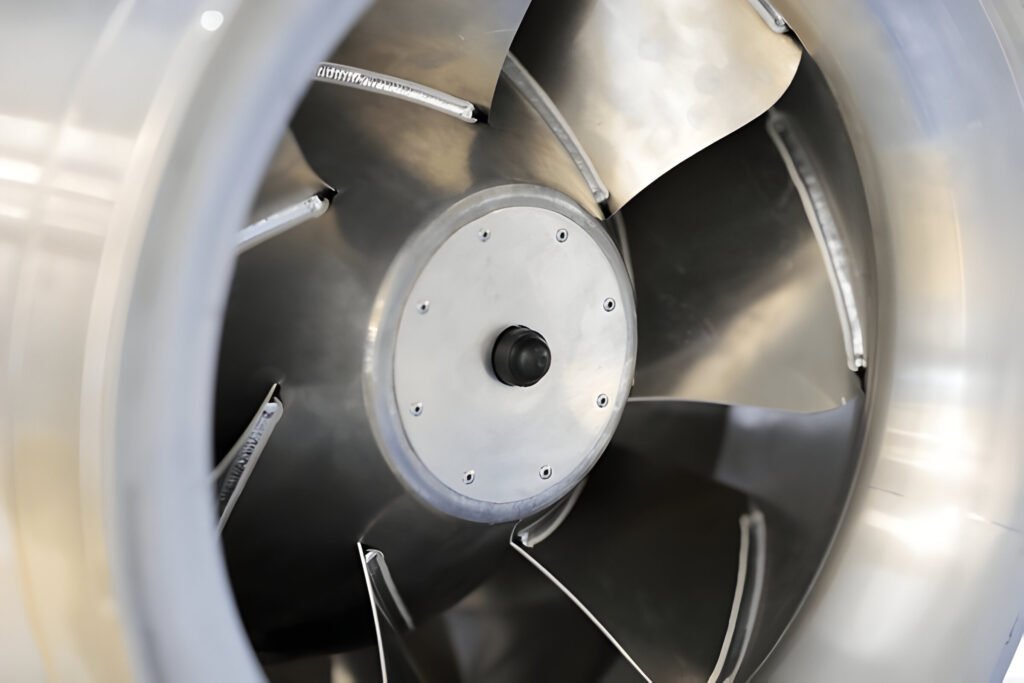

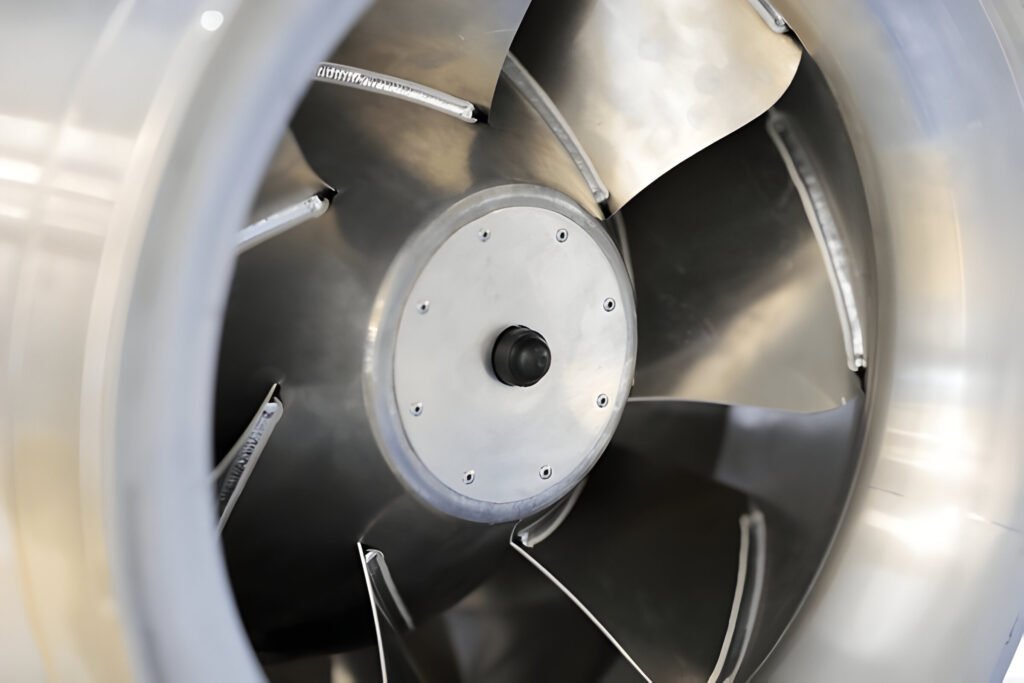

Tube axial fans consist of a cylindrical housing with an axial-flow impeller inside. The impeller, made of metal or reinforced plastic, has multiple blades attached to a central hub. Rotating impellers move air parallel to the shaft, creating airflow through the cylindrical casing.

These fans generate high-volume airflow with moderate pressure. Common applications include HVAC systems, industrial ventilation, and cooling in factories, warehouses, and commercial buildings.

Tube axial fans operate on a pressure difference principle. A cylindrical housing contains a propeller-like fan. The rotating fan blades create a pressure gradient between the inlet and outlet, forcing air to flow through the tube parallel to the rotation axis.

The fan motor spins the blades at high speeds. Angled blades push air, generating a low-pressure area in front and a high-pressure area behind. This pressure differential drives air movement from the low to high-pressure side.

Propellers and impellers form the core of tube axial fans, driving air movement through the system. These rotating components feature multiple blades attached to a central hub, designed for efficient directional air flow.

Tube axial fan housings direct airflow and protect internal components. The cylindrical structure encases the propeller or impeller, maximizing efficiency and performance.

Inlet and outlet flanges or mounting brackets facilitate installation and connection to ductwork. Some housings feature adjustable inlet vanes or outlet dampers for airflow control.

Electric motors power tube axial fans, converting electrical energy to mechanical energy. Common types include AC induction motors and DC brushless motors. The motor’s size and power output determine the fan’s airflow rate and static pressure capabilities.

Bearings support the rotating shaft and reduce friction in tube axial fans. Two main types are used: ball bearings and sleeve bearings.

Ball bearings contain small metal balls rolling between circular tracks. They offer durability and handle radial and axial loads. High-speed applications and harsh environments often use ball bearings. They require less maintenance and last longer than sleeve bearings.

Sleeve bearings, or bushings, are cylindrical sleeves surrounding the shaft. Made from bronze or synthetic compounds, they use a thin lubricant film to reduce friction. Smaller fans and those designed for quiet operation typically use sleeve bearings. They cost less but may need more frequent maintenance and replacement.

Inspection doors on tube axial fans allow access to internal components for maintenance and repair. Located on the fan housing, these doors enable inspection, cleaning, and servicing without full disassembly.

Belt-driven tube axial fans use V-belts or synchronous belts to transmit power from the motor to the impeller. V-belts offer cost-effectiveness, while synchronous belts provide precise speed control and higher efficiency. Cast iron or aluminium pulleys come in various sizes to achieve desired speed ratios.

Tube axial fans offer two drive options: direct and belt-driven.

Direct-driven fans mount the impeller on the motor shaft, eliminating belts and pulleys. This configuration reduces moving parts, lowering maintenance needs and potentially increasing reliability.

Belt-driven fans allow for precise speed control and motor isolation from the airstream. They suit applications requiring these features or where maintenance access is easier.

Direct drive tube axial fans mount the fan blade directly onto the motor shaft, eliminating belts or intermediary components. This configuration offers advantages for ventilation systems.

These fans are compact and require less installation space. They achieve higher energy efficiency due to the absence of power loss through belt drives or gear systems. Maintenance is simplified with fewer moving parts to replace.

Direct drive fans excel at higher speeds, suitable for high airflow applications. They operate more quietly than belt-driven models, lacking belt noise and vibration.

Belt drive tube axial fans employ a belt and pulley system to connect the motor to fan blades. This configuration offers versatility and quieter operation compared to direct drive fans. Speed adjustments are achieved by changing pulley sizes, and the belt absorbs motor vibrations.

These fans excel in applications requiring flexible motor placement. The motor can be positioned away from the airstream, benefiting high-temperature environments or corrosive gas handling. Maintenance is simplified, as belt replacement does not require full fan disassembly.

Belt drive fans have lower efficiency than direct drive models due to energy loss in the belt system.

Tube axial fans deliver high airflow with minimal energy consumption. Their streamlined design, featuring blades mounted directly on the motor shaft, reduces friction and energy loss. This configuration enables efficient power transfer from the motor to air movement.

Cylindrical housing of tube axial fans enables installation in confined spaces. The compact design fits areas inaccessible to other fan types, integrating seamlessly into existing ductwork or ventilation systems. This feature makes tube axial fans suitable for retrofitting projects.

Tube axial fans feature robust construction for harsh industrial environments.

These fans maintain performance in extreme temperatures, from sub-zero to high-heat settings. Their design resists chemical exposure, making them suitable for various industrial applications.

Advanced blade design enables low noise operation in tube axial fans. These fans use engineered blades with optimized shapes, angles, and profiles to minimize turbulence and air resistance. The result is smoother airflow and reduced noise levels compared to other fan types.

Tube axial fans struggle in high-pressure applications. They perform inefficiently when moving air against significant resistance, functioning best in low to medium pressure environments.

These fans handle particulates and debris poorly, limiting their use in industrial settings with poor air quality or risk of larger particles. They produce noise at higher speeds, creating issues in sound-sensitive areas.

Tube axial fans exhibit lower efficiency compared to other fan types, especially at reduced speeds. This results in higher energy consumption for equivalent airflow. Their narrow operating range restricts versatility in applications with varying airflow needs.

The straight-through design of tube axial fans complicates maintenance and cleaning, potentially increasing long-term operating costs. This design feature can make accessing internal components more challenging, leading to more time-consuming and costly maintenance procedures.

Tube axial fans serve diverse applications across industries. They excel in moving large air volumes, making them suitable for industrial ventilation and cooling. Factories, warehouses, and manufacturing plants commonly employ these fans.

HVAC systems and cooling towers utilize tube axial fans extensively. Power plants incorporate them for generator cooling. Mining operations rely on these fans for underground ventilation, ensuring fresh air supply in potentially hazardous environments.

Agricultural settings use tube axial fans for crop drying and livestock ventilation. The marine industry installs them on ships for engine room and cargo hold air circulation. Tunnel ventilation systems depend on these fans to maintain air quality and remove exhaust fumes.

Air density significantly affects tube axial fan performance. Higher air density increases the fan’s air movement capacity due to more molecules per unit volume.

Tube axial fans typically feature three to eight blades. More blades increase air pressure but reduce airflow due to higher solidity. Fewer blades provide higher airflow rates at lower pressures.

Straight blades offer simplicity and cost-effectiveness. They are easy to produce and maintain but may need more efficiency compared to other designs.

Curved blades enhance aerodynamic performance. Forward-curved blades generate high air volume at low pressures, suitable for high-airflow, low-resistance applications. Backwards-curved blades excel in high-pressure scenarios and offer improved efficiency at higher speeds.

Airfoil-shaped blades provide maximum efficiency. They minimize drag and maximize lift, optimizing air movement. However, their complex design and manufacturing process makes them the most expensive option.

Tubeaxial and vane axial fans differ in design and performance.

Tubeaxial fans feature a propeller-like blade assembly in a cylindrical housing. They offer high airflow but lower pressure capabilities.

Vane axial fans include guide vanes before or after the impeller. These vanes straighten airflow, reduce turbulence, and increase efficiency. Vane axial fans generate higher pressures than tube axial fans.

Tubeaxial fans cost less and require simpler maintenance due to their basic design. They suit applications needing high volume airflow at low pressures. Vane axial fans, though more complex and expensive, perform better in high-pressure situations.

Standard tube axial fans are unsuitable for explosive environments.

Tube axial fans typically offer higher energy efficiency than centrifugal fans, especially for moving large air volumes at low pressure.

Tube axial fans typically last 10-15 years with proper maintenance.