Different Types of Electric Motors

Explore the various types of electric motors, their working principles, applications, and key differences.

Read More

In the world of machinery, the choice between ball bearing and sleeve bearingcan significantly impact performance, longevity, and cost.

This blog post will delve into the intricacies of ball bearing and sleeve bearing, examining their unique characteristics, advantages, and disadvantages.

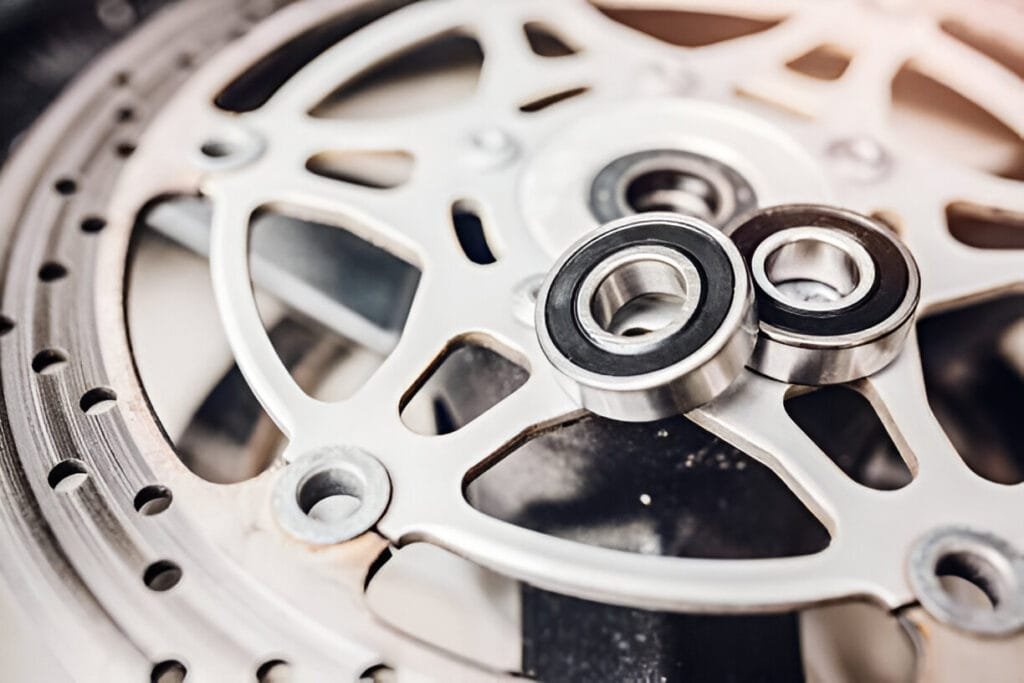

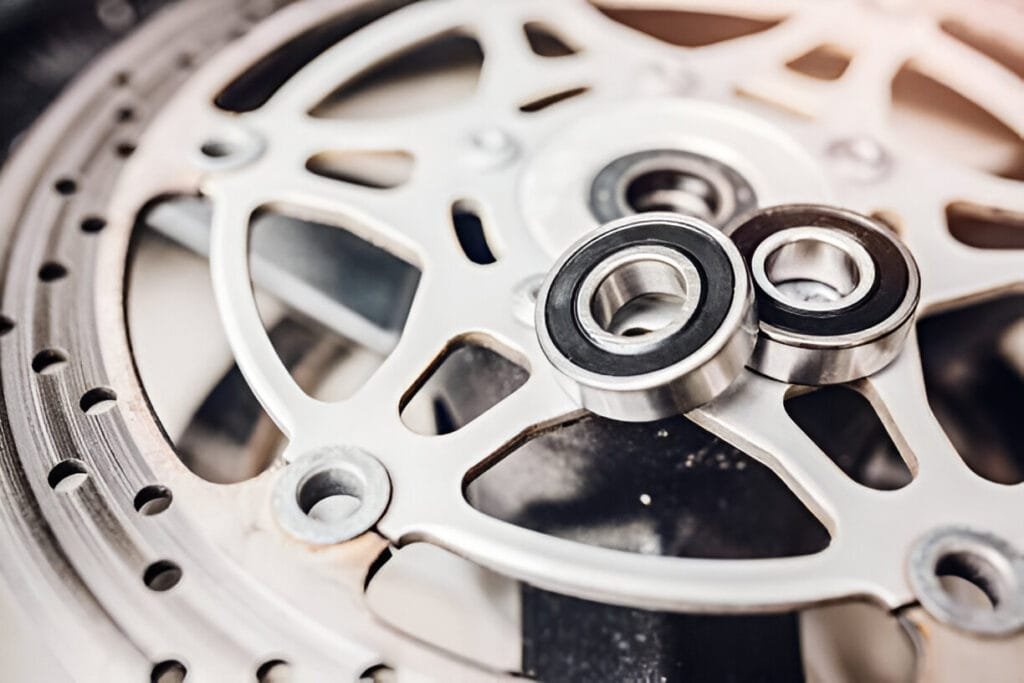

Ball bearings are a type of bearing that uses small, hardened metal balls to maintain the separation between the bearing races while simultaneously reducing rotational friction and supporting radial and axial loads. The balls are rolled between two circular metal ring structures, known as races. The inner race is typically mounted on a rotating shaft, while the outer race is held stationary within a bearing housing.

As the inner race rotates with the shaft, the balls roll within the races with minimal friction, allowing for smooth and efficient operation. The balls are often guided by a cage or separator, which maintains even spacing between the balls and prevents them from contacting each other during operation.

Sleeve bearings, also known as bushings or fluid bearings, are a type of bearing that utilize a cylindrical sleeve to support the rotating shaft of a fan. Unlike ball bearings, which use rolling elements, sleeve bearings rely on a thin film of lubricant between the shaft and the sleeve to reduce friction and ensure smooth operation.

In operation, the fan shaft rotates within the sleeve, with the lubricant providing a low-friction interface between the two surfaces. The lubricant, which can be oil or grease, is typically embedded within the pores of the sleeve material and is gradually released over time to maintain a consistent film between the shaft and sleeve.

When selecting between ball bearing and sleeve bearing fans for your application, several crucial factors must be taken into account to ensure optimal performance, reliability, and cost-effectiveness. These key considerations include lifespan and durability, mounting orientation flexibility, noise levels, temperature tolerance, and cost.

Ball bearing fans typically offer longer life spans compared to their sleeve bearing counterparts due to the design of ball bearings, which feature metal balls that rotate between inner and outer races, minimizing friction and wear. This reduced friction allows ball bearing fans to maintain consistent performance over extended periods.

In contrast, sleeve bearings rely on a film of lubricant between the bearing surface and the rotating shaft. Over time, this lubricant can deteriorate or break down, leading to increased friction and wear on the bearing surfaces. As a result, sleeve bearing fans generally have shorter life expectancies than ball bearing fans, especially in demanding applications or challenging environmental conditions.

Ball bearings provide greater versatility in terms of mounting positions, as they can effectively handle both radial and axial loads. This allows ball bearing fans to be mounted in various orientations, including horizontal, vertical, and other non-vertical positions, without significant impact on their performance or lifespan.

Sleeve bearings, on the other hand, have more limited mounting options due to their reliance on the lubricant film for proper operation. Sleeve bearing fans are best suited for horizontal or vertical orientations where the bearing can maintain consistent contact with the lubricant. Mounting sleeve bearing fans in non-vertical positions can lead to uneven lubricant distribution, resulting in premature wear and reduced bearing life.

Sleeve bearing fans generally offer quieter operation at lower speeds due to the smooth, fluid motion of the lubricant film between the bearing and shaft. This makes sleeve bearings an attractive choice for low-noise applications or environments where minimal acoustic disturbance is desired.

Ball bearing fans, while offering superior durability and mounting flexibility, can produce slightly higher noise levels at lower speeds due to the rolling contact between the metal balls and races. However, at higher speeds, ball bearing fans often exhibit lower noise levels compared to sleeve bearing fans, as the lubricant film in sleeve bearings can become unstable, leading to increased noise and vibration.

Temperature tolerance is a crucial factor to consider, especially in applications where the fan will be exposed to high ambient temperatures or where the fan itself generates considerable heat. Ball bearings offer superior temperature tolerance compared to sleeve bearings, thanks to their design and materials. The metal-to-metal contact in ball bearings allows for better heat dissipation, enabling them to operate reliably in higher temperature environments.

Sleeve bearings, in contrast, are more susceptible to heat-related issues due to their reliance on the lubricant film. As temperatures rise, the lubricant can thin out or break down, leading to increased friction, wear, and potential bearing failure. This makes sleeve bearings less suitable for applications with high operating temperatures or where the fan is responsible for cooling heat-sensitive components.

Sleeve bearing fans typically have a lower initial cost compared to ball bearing fans due to their simpler construction and fewer components. This makes sleeve bearings an attractive choice for cost-sensitive applications or projects with tight budget constraints.

However, it is important to consider the total cost of ownership when making a decision. While ball bearing fans may have a higher upfront cost, their longer lifespan, improved durability, and consistent performance can result in lower maintenance and replacement costs over time. In applications where long-term reliability and minimal downtime are critical, the higher initial investment in ball bearing fans may be justified.

In applications where the expected lifespan of the fan is relatively short, operating temperatures are low, and the fan will be mounted vertically, sleeve bearing fans are often the most cost-effective choice. Sleeve bearings rely on a thin film of lubricant between the bearing surfaces, which allows for quiet operation at low speeds. This makes them well-suited for applications such as office equipment, audio systems, and other environments where low noise levels are a priority.

However, it’s important to note that sleeve bearings have limitations in terms of lifespan and heat dissipation. The lubricant within sleeve bearings can deteriorate over time, leading to increased friction and reduced performance. Additionally, sleeve bearings are not designed to handle significant amounts of heat, as high temperatures can cause the lubricant to break down more quickly.

For applications that demand a longer lifespan, higher temperature tolerance, and flexibility in mounting orientation, ball bearing fans are the superior choice. Ball bearings feature a series of metal balls that rotate between two circular metal structures, providing a low-friction and durable solution for fan rotation.

The design of ball bearings allows them to handle higher speeds, greater radial and axial loads, and more challenging environmental conditions compared to sleeve bearings. They can operate reliably in both vertical and non-vertical positions, making them suitable for a wide range of industrial, automotive, and high-performance computing applications.

Ball bearings also excel in terms of heat dissipation, as they can withstand higher ambient temperatures without experiencing rapid deterioration of the lubricant. This is particularly important in applications where the fan is responsible for cooling heat-sensitive components, such as in computer systems or industrial machinery.

While ball bearing fans typically have a higher initial cost compared to sleeve bearing fans, their longer lifespan and consistent performance often make them a more cost-effective choice in the long run. The reduced friction and improved efficiency of ball bearings can also contribute to energy savings over the life of the fan.

When selecting between sleeve bearings and ball bearings for your specific application, consider factors such as the required lifespan, operating temperatures, mounting orientation, noise requirements, and budget constraints. By weighing these factors and understanding the strengths and limitations of each bearing type, you can make an informed decision that ensures optimal fan performance and reliability in your unique application.

To determine whether a motor uses sleeve bearings or ball bearings, consider the following factors: