Centrifugal fans are designed to operate in a specific direction, with the blades oriented to move air from the inlet to the outlet. While it may seem like a simple matter to reverse the direction of a centrifugal fan, doing so can lead to significant performance issues and potential damage to the equipment.

This blog post will delve into the technical reasons why running a centrifugal fan backwards is not recommended and the consequences of doing so.

Signs of Reverse Rotation

When a centrifugal fan is running backwards, there are several key indicators that can alert you to the issue. These signs include reduced efficiency, decreased air movement, increased system noise, and changes in power consumption.

Reduced Efficiency

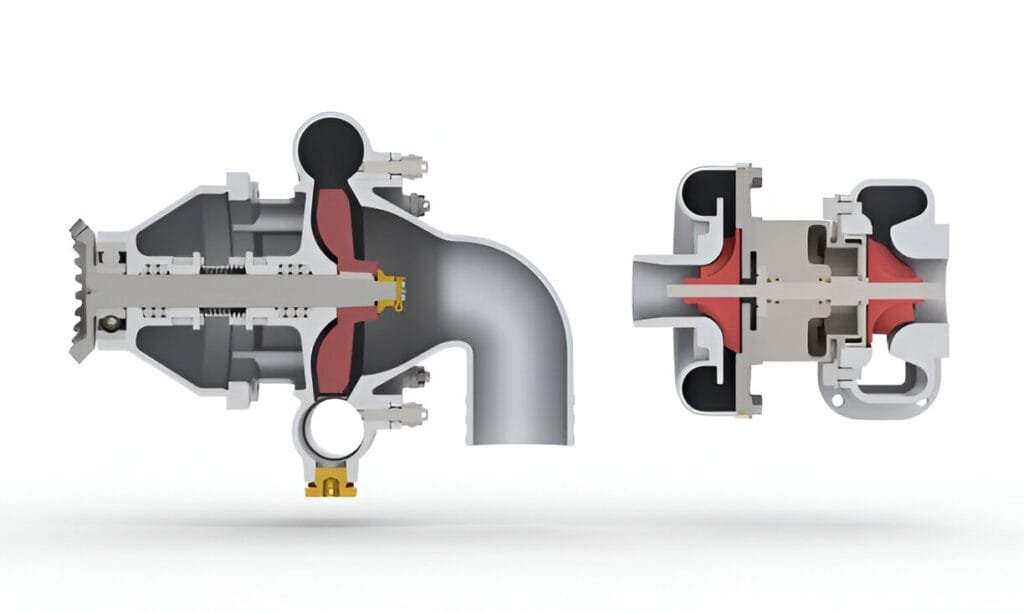

One of the most significant signs of a centrifugal fan running in the wrong direction is a noticeable decrease in efficiency. The curved blades of a centrifugal fan are designed to move air efficiently when rotating in the correct direction. However, when the fan operates in reverse, the blade curvature works against the intended airflow, leading to a substantial reduction in the fan’s ability to generate the desired air volume and static pressure.

Reduced Air Movement

Another clear indicator of reverse rotation is a significant reduction in air movement. Centrifugal fans are designed to move large volumes of air efficiently, creating the necessary pressure difference to overcome system resistance. When a fan runs backwards, its ability to generate the required airflow is severely compromised.

Increased System Noise

Reverse rotation can also cause a noticeable increase in system noise. When a centrifugal fan operates in the correct direction, the interaction between the rotating impeller and the air results in a relatively smooth and quiet operation. However, when the fan runs backwards, the airflow becomes turbulent and less efficient, leading to increased noise levels.

This noise can manifest as a high-pitched whine, a rumbling sound, or a general increase in the overall sound pressure level.

Power Consumption Changes

Finally, reverse rotation can lead to changes in power consumption. When a centrifugal fan runs in the correct direction, it operates at its designed efficiency point, consuming the expected amount of power. However, when the fan runs backwards, its efficiency drops, and the motor must work harder to maintain the desired output.

This increased load on the motor can result in higher power consumption, leading to increased energy costs and potential motor overheating. In some cases, the motor may even trip its overload protection or fail prematurely due to the added stress of operating in reverse.

Causes of Reverse Rotation

Centrifugal fans are designed to rotate in a specific direction to achieve optimal performance, delivering the required airflow and pressure for a wide range of applications. However, several factors can lead to a centrifugal fan running backwards, resulting in reduced efficiency, decreased air volume, and increased noise levels.

Electrical Wiring Mistakes

One of the most common causes of reverse rotation in centrifugal fans is incorrect electrical wiring. In three-phase AC motors, which are frequently used in centrifugal fan applications, the direction of rotation is determined by the sequence of the electrical connections. If any two of the three power leads are accidentally swapped during installation or maintenance, the motor will rotate in the opposite direction.

Motor Connection Errors

In addition to electrical wiring mistakes, errors in motor connections can also cause a centrifugal fan to rotate in the wrong direction. Centrifugal fans often use direct drive mechanisms, where the motor is directly coupled to the impeller or fan wheel. If the motor is connected to the impeller incorrectly during assembly or maintenance, the fan will rotate backwards.

Installation Procedural Failures

Failure to follow the manufacturer’s installation guidelines, including proper mounting, ductwork connections, and system integration, can lead to reverse rotation issues.

One critical aspect of installation is the proper orientation of the fan housing and ductwork. Centrifugal fans are designed with specific inlet and outlet configurations to optimize airflow and pressure development. If the fan housing is installed incorrectly or the ductwork is connected to the wrong inlet or outlet, the fan may rotate in the opposite direction, leading to reduced performance and potential system damage.