Centrifugal fans are a critical component in many industrial processes, playing a vital role in moving air and gases. These versatile machines convert rotational kinetic energy into an increase in the pressure and flow of a gas through the use of an impeller rotating within a spiral or volute housing.

In this post, we will take a deep dive into inline centrifugal fans, exploring their working principles, the various types of impellers used, as well as their key advantages, limitations, and common applications.

What Is an Inline Centrifugal Fan

An inline centrifugal fan is a type of mechanical fan that utilizes centrifugal force to increase the pressure and flow rate of air or gases. These fans are widely used in various industrial applications for ventilation, exhaust, and air conditioning systems.

Inline centrifugal fans are designed to be installed directly within the ductwork of a system, allowing for efficient air movement without the need for additional transitions or elbows. This inline configuration makes them suitable for applications where space is limited or where the fan needs to be hidden from view.

Working Principle of Centrifugal Fans

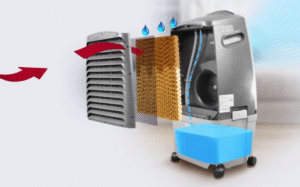

Centrifugal fans operate based on the principle of centrifugal force. They consist of an impeller, which is a rotating device with blades, that is mounted on a shaft and driven by a motor. As the impeller rotates, it draws air in from the center and accelerates it radially outward due to centrifugal force.

The blades on the impeller are angled to direct the airflow away from the center and towards the outer edge of the impeller. This action increases the kinetic energy of the air, resulting in an increase in pressure. The high-pressure air is then discharged through the outlet of the fan housing into the ductwork or desired space.

Types of Impellers

Forward-Curved Blades

Forward-curved impellers have blades that curve in the direction of rotation. These impellers are known for their high airflow capacity and low noise levels. However, they are less efficient compared to other types of impellers and are more prone to overloading if the system resistance changes.

Backward-Inclined Blades

Backward-inclined impellers have blades that slope away from the direction of rotation. They are more efficient than forward-curved impellers and can handle higher static pressures. Backward-inclined impellers are commonly used in applications that require higher pressure or where greater energy efficiency is desired.

Radial Blades

Radial impellers have straight blades that extend radially from the center of the impeller. These impellers are known for their simplicity and durability. They are often used in applications where high static pressures are required, such as in material handling or dust collection systems.

Airfoil Blades

Airfoil impellers have blades with a cross-section similar to that of an aircraft wing. These impellers offer the highest efficiency among all types and are designed to minimize turbulence and noise. Airfoil impellers are commonly used in applications where high efficiency and low noise levels are critical.

Advantages of Centrifugal Fans

High Pressure Capabilities

Centrifugal fans are capable of generating high pressures, making them suitable for applications that require overcoming significant system resistance, such as long ductwork runs or filtration systems.

Compact Design

Inline centrifugal fans have a compact design that allows for easy installation within ductwork. This feature makes them ideal for applications where space is limited, as they can be seamlessly integrated into existing systems without requiring additional space.

Energy Efficiency

Centrifugal fans, particularly those with backward-inclined or airfoil blades, offer high energy efficiency. These fans can move large volumes of air with minimal power consumption, resulting in reduced operating costs and energy savings.

Durability

Centrifugal fans are known for their durability and long service life. They are built with robust materials and can withstand continuous operation in demanding environments. With proper maintenance, centrifugal fans can provide reliable performance for extended periods.

Disadvantages of Centrifugal Fans

Noise Generation

Centrifugal fans can generate noise, especially at high speeds or when operating at high pressures. The noise levels depend on factors such as impeller design, fan speed, and system configuration. Proper noise attenuation measures, such as sound attenuators or acoustic enclosures, may be necessary in noise-sensitive environments.

Sensitivity to System Changes

Centrifugal fans, particularly those with forward-curved blades, are sensitive to changes in system resistance. If the system resistance increases beyond the design point, the fan may experience overloading, leading to reduced performance and potential damage to the motor or impeller. Proper system design and fan selection are crucial to ensure optimal performance.

Higher Initial Cost

Centrifugal fans, especially those with advanced impeller designs like backward-inclined or airfoil blades, may have a higher initial cost compared to other types of fans. However, the long-term energy savings and durability of centrifugal fans often justify the investment.

Applications of Centrifugal Fans

HVAC Systems

Centrifugal fans are commonly used in heating, ventilation, and air conditioning (HVAC) systems for buildings. They are used to circulate conditioned air through ductwork and distribute it to different spaces within a building. Centrifugal fans help maintain indoor air quality, temperature control, and comfort levels.

Industrial Ventilation

Centrifugal fans are employed in various industrial settings for ventilation purposes. They are used to remove heat, fumes, dust, and other airborne contaminants from manufacturing processes, ensuring a safe and healthy working environment for employees. Industrial centrifugal fans are designed to handle large volumes of air and withstand harsh operating conditions.

Exhaust Systems

Centrifugal fans are used in exhaust systems to remove stale air, odors, and pollutants from indoor spaces. They are commonly found in commercial kitchens, laboratories, and industrial facilities where effective exhaust is crucial. Centrifugal fans help maintain indoor air quality and comply with ventilation regulations.

Process Cooling

In industrial processes that generate heat, centrifugal fans are used for cooling purposes. They can provide cooling air for machinery, electronic equipment, and manufacturing processes. Centrifugal fans help dissipate heat and maintain optimal operating temperatures, preventing equipment damage and ensuring process efficiency.

Agricultural Ventilation

Centrifugal fans are used in agricultural applications, such as greenhouse ventilation and livestock housing. They help regulate temperature, humidity, and air quality in these environments, promoting healthy plant growth and animal well-being. Centrifugal fans provide uniform air distribution and can be integrated with climate control systems.

## FAQs

What is the difference between an inline centrifugal fan and a regular centrifugal fan

An inline centrifugal fan is designed to be installed directly within the ductwork, while a regular centrifugal fan is typically mounted externally and connected to the ductwork via transitions.

Can inline centrifugal fans be used for both supply and exhaust applications

Yes, inline centrifugal fans can be used for both supply and exhaust applications, depending on the specific requirements of the system.

How do I select the right size of inline centrifugal fan for my application

Selecting the right size of inline centrifugal fan involves considering factors such as the required airflow rate, system static pressure, available space, and noise requirements. It is recommended to consult with a professional or refer to the manufacturer’s guidelines for proper sizing.

What maintenance is required for inline centrifugal fans

Regular maintenance for inline centrifugal fans includes cleaning the impeller and housing, lubricating bearings (if applicable), checking for any vibrations or unusual noises, and inspecting the motor and electrical connections. Refer to the manufacturer’s recommendations for specific maintenance guidelines.

Can inline centrifugal fans be used in high-temperature applications

Yes, some inline centrifugal fans are designed to handle high-temperature applications. These fans are constructed with materials that can withstand elevated temperatures and may feature special cooling mechanisms for the motor.