In the machinery industry, fans are ubiquitous components that serve various purposes, from ventilation and cooling to material handling and drying. Two common types of fans frequently used in industrial settings are centrifugal fans and inline fans, each with distinct characteristics and applications.

This blog post will delve into the key differences between centrifugal fans and inline fans, focusing on aspects such as airflow direction, pressure capability, energy efficiency, noise, installation, and typical applications. By understanding these distinctions, professionals in the machinery industry can make informed decisions when selecting the most suitable fan type for their specific requirements.

What Is Centrifugal Fan

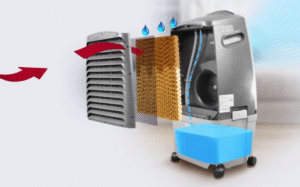

A centrifugal fan is a mechanical device that utilizes rotating impellers to move air or gases. The impeller, which consists of a central hub with multiple blades attached, spins at high speeds within a scroll-shaped housing. As the impeller rotates, it draws air in through the center and accelerates it radially outward using centrifugal force.

The airflow generated by a centrifugal fan is perpendicular to the shaft axis. The air enters the fan axially and is discharged radially, 90 degrees from the inlet direction. This design allows centrifugal fans to generate higher pressures compared to other fan types.

What Is Inline Fan

An inline fan, also known as a duct fan or tubular fan, is a type of fan designed to be installed directly within a ducting system. Unlike centrifugal fans, inline fans have a compact, cylindrical housing that allows for easy integration into ductwork without significant modifications.

Inline fans feature an axial impeller, which consists of a central hub with blades attached. As the impeller rotates, it draws air in from one end of the fan and pushes it out the other end, creating a straight-through airflow path. The airflow direction is parallel to the fan’s shaft axis.

Key Differences Between Centrifugal Fans and Inline Fans

Airflow Direction

One of the primary differences between centrifugal fans and inline fans is the direction of airflow. Centrifugal fans draw air in through the inlet, which is parallel to the fan’s shaft, and then redirect the airflow perpendicularly using the centrifugal force generated by the rotating impeller. The air is discharged radially, typically through a scroll-shaped housing.

In contrast, inline fans move air along a straight line, parallel to the fan’s shaft. The airflow enters and exits the fan in the same direction, making inline fans suitable for applications where the air needs to be moved from one point to another without changing direction.

Pressure Capability

Centrifugal fans are known for their ability to generate higher pressures compared to inline fans. The centrifugal force created by the rotating impeller allows these fans to overcome greater resistance in the system, such as static pressure drops caused by ductwork, filters, or other components. This makes centrifugal fans suitable for applications that require high pressure, such as industrial exhaust systems or dust collection.

Inline fans, on the other hand, are designed for lower pressure applications. They are more effective in systems with minimal resistance, such as short duct runs or open-air circulation. Inline fans are commonly used in applications where the primary goal is to move a large volume of air rather than overcoming significant pressure drops.

Energy Efficiency

The energy efficiency of centrifugal fans and inline fans can vary depending on the specific design and application. However, inline fans generally have a slight advantage in terms of energy efficiency due to their simpler design and lower pressure requirements.

Centrifugal fans, especially those designed for high-pressure applications, may consume more energy to overcome the system resistance. However, advancements in impeller design and motor technology have led to the development of more energy-efficient centrifugal fans.

Noise

Noise levels are another factor to consider when comparing centrifugal fans and inline fans. Centrifugal fans tend to generate more noise due to the high-pressure air movement and the turbulence created within the scroll housing. The noise level can be particularly noticeable in high-speed or high-pressure applications.

Inline fans, with their straight-through airflow design, typically produce less noise compared to centrifugal fans. The absence of a scroll housing and the lower pressure requirements contribute to reduced turbulence and noise levels. However, the noise generated by an inline fan can still be significant, especially in larger sizes or high-flow applications.

Installation

The installation requirements for centrifugal fans and inline fans differ based on their design and application. Centrifugal fans are typically mounted on a solid base or platform, with the inlet and outlet connections oriented perpendicular to each other. The scroll housing and motor position can be customized to suit the specific installation requirements.

Inline fans are designed for easy installation within ductwork or other air passages. They have a compact, cylindrical housing that allows them to be mounted directly in line with the airflow path. Inline fans often come with mounting brackets or flanges for secure installation.

Applications

Centrifugal fans and inline fans are used in a wide range of applications, each suited to their specific strengths and characteristics. Centrifugal fans are commonly found in:

- Industrial exhaust systems

- Dust collection systems

- HVAC systems with high static pressure requirements

- Drying and cooling processes

- Air pollution control systems

Inline fans are frequently used in:

- Residential and commercial ventilation systems

- Duct boosting applications

- Air circulation and cooling in open spaces

- Fume and odor extraction systems

- Clean room ventilation systems