Can You Run a Centrifugal Fan Backwards

Exploring the functionality and potential consequences of running a centrifugal fan in reverse.

Read More

Centrifugal fans and mixed flow fans are two essential types of industrial fans widely used in various applications. While both fans are designed to move air, they differ in their construction, performance characteristics, and suitable applications.

In this blog post, we will delve into the unique features and advantages of each fan type, focusing on aspects such as airflow direction, pressure capability, flow rate, noise levels, blade shapes, and typical applications.

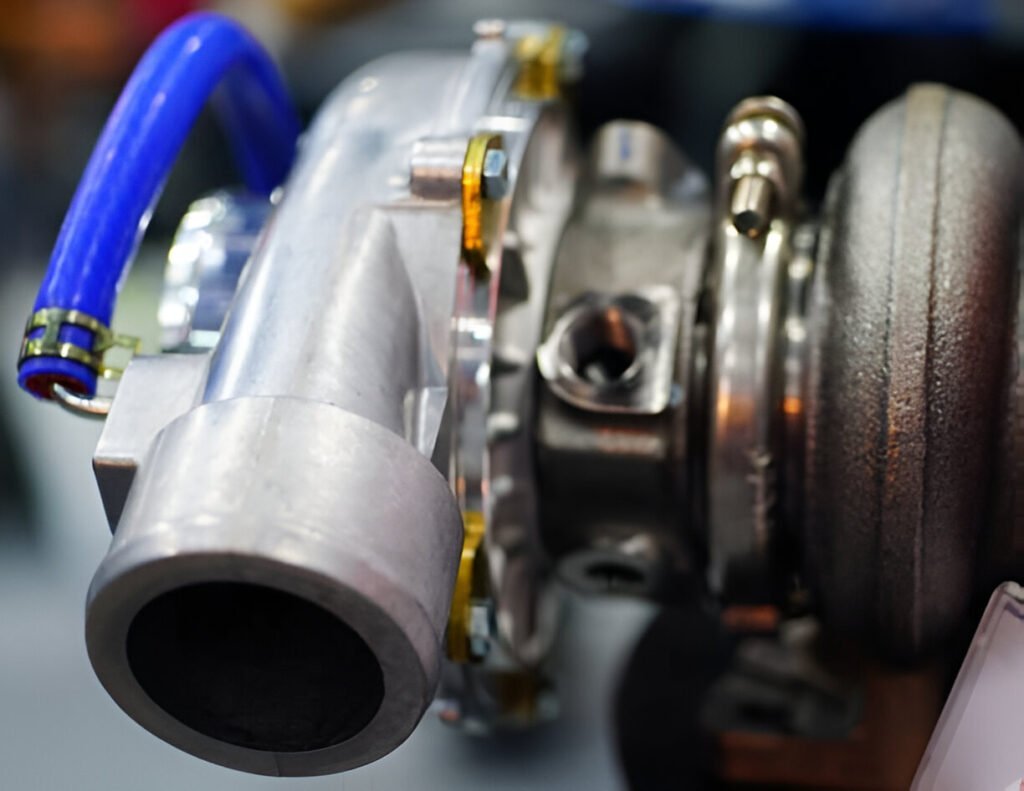

A centrifugal fan is a type of fan that moves air by using the centrifugal force generated by a rotating impeller. The impeller, which consists of a series of blades mounted on a circular hub, spins at high speeds within the fan housing. As the impeller rotates, it draws air into the center of the fan and accelerates it radially outward through the blades. The centrifugal force created by this rotation causes the air to be expelled perpendicular to the shaft, creating a high-pressure flow.

A mixed flow fan is a type of fan that combines the characteristics of both axial and centrifugal fans, hence the name “mixed flow.” In a mixed flow fan, the airflow enters the impeller axially and is then gradually turned and accelerated, exiting the fan in a direction that is diagonal to the impeller’s axis of rotation. This unique design allows mixed flow fans to deliver high flow rates while maintaining moderate pressure capabilities.

When comparing centrifugal fans and mixed flow fans, there are several key differences to consider. These distinct fan types vary in their airflow direction, pressure capabilities, flow rates, noise levels, blade shapes, and typical applications.

In centrifugal fans, the airflow enters the fan parallel to the shaft and is discharged perpendicular to the shaft, creating a 90-degree turn in the flow direction.

Mixed flow fans feature airflow that enters axially and exits at an angle, usually between 30 and 70 degrees relative to the fan axis. This unique airflow direction allows mixed flow fans to combine the benefits of both centrifugal and axial fans.

Centrifugal fans are known for their ability to generate higher static pressures compared to mixed flow fans. They are well-suited for applications requiring medium to high-pressure airflow, such as ducted systems and industrial processes.

Mixed flow fans excel in low to medium pressure applications, making them ideal for scenarios demanding a balance between pressure and airflow volume.

Buy the Industrial Fiberglass Centrifugal Fan FB4-72 now and enjoy discounts on purchases over 500 units. Enjoy numerous savings and help your factory achieve efficient ventilation!

When it comes to flow rate, mixed flow fans typically achieve higher airflow rates than centrifugal fans of similar size. The unique design of mixed flow fan blades allows for efficient air movement, enabling them to handle larger volumes of air in a compact package.

Generally, mixed flow fans operate at lower noise levels compared to centrifugal fans due to their aerodynamic design and lower operating speeds. The streamlined airflow path and reduced turbulence in mixed flow fans contribute to quieter operation.

Centrifugal fans typically feature backward-curved, forward-curved, or radial blades, each with its own performance characteristics. These blade designs are optimized for specific pressure and flow requirements.

Mixed flow fans employ a combination of axial and centrifugal blade geometries, often with airfoil-shaped or curved blades. This hybrid blade design allows mixed flow fans to achieve a balance between static pressure and airflow volume.

Centrifugal fans are commonly used in HVAC systems, industrial processes, dust collection, and material handling. They are well-suited for applications requiring high pressures, such as in ducted systems or when overcoming resistance in filters or other components.

Mixed flow fans are widely used in applications that demand high airflow rates and moderate pressures. They are prevalent in cooling towers, automotive and aircraft ventilation, wind tunnels, and marine vessels.

Centrifugal fans expel air perpendicularly (90°) to the intake, while mixed flow fans discharge air at an oblique angle, blending axial and radial airflow for smoother transitions and less turbulence.

Mixed flow fans are generally more compact and lighter, often inline designs suitable for tight spaces, whereas centrifugal fans require larger housings and heavier bases.