What Is the Difference Between Electric Fan and Clutch Fan

Electric fans run continuously, while clutch fans engage and disengage based on engine temperature to improve efficiency.

Read More

Fan blade and impellers are two distinct components found in various industrial machinery and equipment. While they both serve to move fluids, their specific designs and operating principles differ in important ways.

In this article, we will explore the key differences between FT35 fan blades and impellers, focusing on their unique functions, designs, applications, flow directions, and pressure generation capabilities. By understanding these critical distinctions, professionals can make informed decisions when selecting and maintaining these vital components in their machinery and systems.

A fan blade is a component of a mechanical fan designed to move air when rotated. Fan blades are typically made from materials such as metal, plastic, or wood and are attached to a rotating hub or shaft.

The shape of a fan blade is designed to efficiently push air in a specific direction as it spins. Most fan blades have an airfoil cross-section, similar to an airplane wing, which creates a pressure difference between the front and back surfaces of the blade. This pressure difference generates lift and propels air in the desired direction.

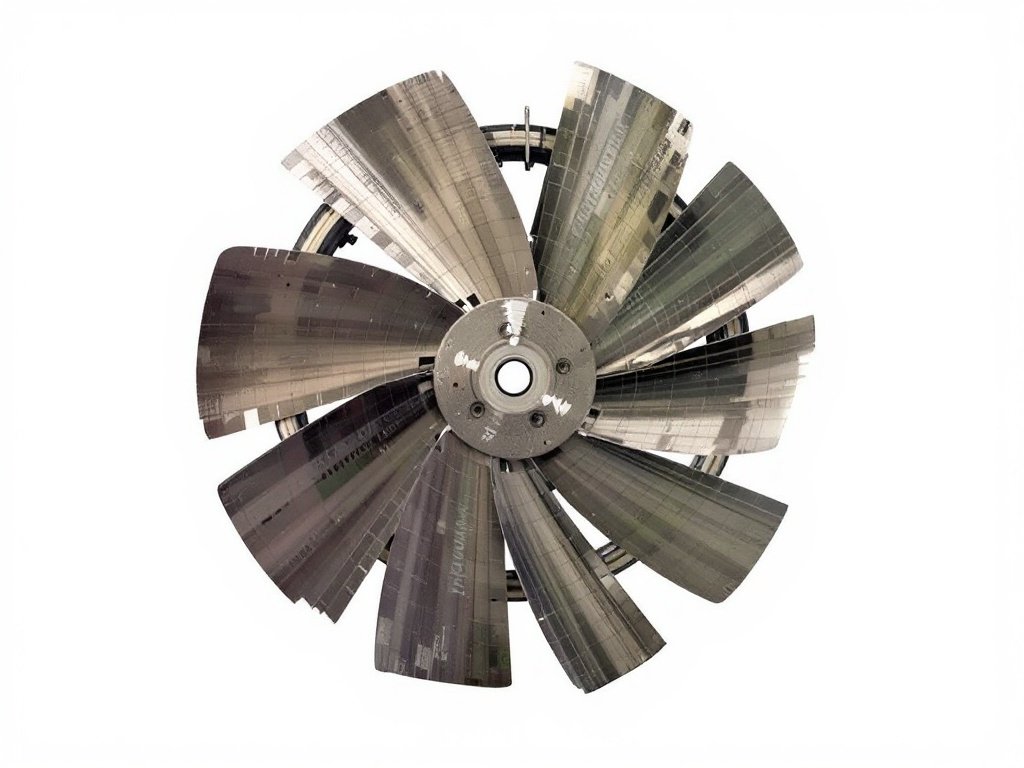

An impeller is a rotating component of a fluid pump or compressor that transfers energy from the motor to the fluid being moved. Impellers are typically made from metal or plastic and consist of a hub with multiple curved vanes or blades radiating outward from the center.

As the impeller rotates, it spins the fluid between the vanes outward from the center of rotation by centrifugal force. This action increases the fluid’s velocity and pressure, allowing it to be pumped or compressed efficiently.

The vanes or blades of an impeller can be open, semi-open, or closed, depending on the application.

Open impellers have vanes without a covering on the sides, while semi-open impellers have a covering on one side. Closed impellers have vanes enclosed by a covering on both sides, making them suitable for applications requiring higher pressures or handling abrasive fluids.

Impellers are used in various applications, including water pumps, automotive fuel and cooling systems, HVAC systems, and industrial processing equipment. They are a critical component in ensuring efficient fluid movement and maintaining proper system performance.

Fan blades and impellers both serve to move fluids, but their specific functions differ. Fan blades are designed to move air or gases, typically for ventilation, cooling, or drying purposes. They generate a high volume of airflow but relatively low pressure.

In contrast, impellers are used to move liquids or gases and can generate higher pressures. They are commonly found in pumps, compressors, and turbines, where they impart energy to the fluid to increase its velocity and pressure.

Boost airflow and comfort with the right fan—choose fan blade or impellers that maximize efficiency for your space.

The design of fan blades and impellers varies based on their intended applications. Fan blades often have a simpler design, with flat or slightly curved surfaces. They are typically longer and narrower compared to impellers.

Impellers, on the other hand, have more complex geometries. They consist of a series of curved vanes or blades arranged radially around a central hub. The curvature and shape of the vanes are carefully engineered to optimize fluid flow and pressure generation.

Fan blades are widely used in various applications, including:

Impellers find applications in a range of industries, such as:

The flow direction of fan blades and impellers differs. Fan blades typically move air in an axial direction, parallel to the shaft on which they are mounted. The airflow enters and exits the fan in the same direction.

Impellers generate radial flow. The fluid enters the impeller axially near the hub and is discharged radially outward from the vane tips. This radial flow is then often converted to an axial direction using a diffuser or volute.

Fan blades generate relatively low pressures compared to impellers. They are designed to move large volumes of air but not to significantly increase its pressure.

Impellers, on the other hand, are capable of generating much higher pressures. The rotating vanes impart kinetic energy to the fluid, which is then converted into pressure energy as the fluid velocity decreases in the diffuser or volute.

Fan blades are flat or curved surfaces that push air, while an impeller is a rotating component that moves air using centrifugal force.

Impellers draw air into the center and push it outward at high speed, creating strong airflow, ideal for high-pressure applications.

Forward-curved blades (for low pressure, high airflow), backward-curved blades (for high pressure and efficiency), and radial blades (balance of pressure and airflow).

Noise can be caused by imbalance, loose parts, motor issues, or dirty blades—regular maintenance helps reduce this.

Consider room size, air circulation needs, and blade design to ensure efficient airflow without excess noise or energy use.