What Is the Difference Between Blowers and Centrifugal Fans

Blowers and centrifugal fans differ in pressure, airflow, and application, with blowers designed for higher pressure systems.

Read More

HVAC fans maintain comfortable indoor environments by circulating air effectively. Understanding the different types of HVAC fans is essential for selecting the right fan for your specific application.

In this ultimate guide, we will explore various types of HVAC fans, including axial, centrifugal, mixed-flow, inline, propeller, and cross-flow fans. We will also delve into the design variations of these fans, such as forward curved, backward curved, and airfoil blades.

Axial fans are a common type of HVAC fan that move air along the axis of the fan, parallel to the shaft. They consist of a cylindrical housing with blades mounted on a central hub, which is connected to a motor. Axial fans are designed to move large volumes of air at relatively low pressures, making them ideal for applications that require high airflow rates.

One of the key advantages of axial fans is their compact size and simple construction. They can be easily installed in ductwork or mounted on walls, making them a versatile choice for various HVAC applications. Axial fans are also known for their energy efficiency, as they require less power to move a given volume of air compared to other fan types.

There are several subtypes of axial fans, including propeller fans, tubeaxial fans, and vaneaxial fans.

Centrifugal fans, also known as radial fans, moves air by utilizing the centrifugal force generated by a rotating impeller. The impeller consists of a series of blades that draw air into the center of the fan and then expel it radially outward through the fan housing.

Centrifugal fans are capable of generating high pressures, making them suitable for applications that require air to be moved through ducting systems or against significant resistance.

Centrifugal fans are commonly used in both residential and commercial HVAC systems. In residential applications, they are often found in furnaces, air handlers, and ventilation systems. In commercial settings, centrifugal fans are employed in larger HVAC systems, such as rooftop units, air conditioning systems, and exhaust systems.

One of the key advantages of centrifugal fans is their ability to handle high static pressures, making them well-suited for systems with extensive ductwork or filtration requirements. They are also relatively compact compared to other fan types, allowing for efficient use of space within HVAC units.

Mixed-flow fans, also known as diagonal fans, combine the characteristics of both axial and centrifugal fans. These fans feature impellers with blades that are positioned at an angle, allowing air to flow both axially and radially. This unique design enables mixed-flow fans to generate higher pressure than axial fans while maintaining a higher flow rate than centrifugal fans.

The angled blade configuration of mixed-flow fans allows for efficient air movement and reduced turbulence. These fans are capable of handling medium to high pressures and can operate at a wide range of airflow rates. Mixed-flow fans are often used in applications that require a balance between high pressure and high flow rate, such as in air handling units, cooling towers, and exhaust systems.

One of the advantages of mixed-flow fans is their compact size compared to other types of fans with similar performance. This space-saving design makes them suitable for installations with limited space. Mixed-flow fans also offer relatively quiet operation, making them a good choice for applications where noise reduction is important.

Inline fans, also known as duct fans or tubular fans, are cylindrical fans designed to be installed directly within the ductwork of an HVAC system. These fans are used to boost airflow in specific sections of the ductwork, helping to overcome resistance caused by long duct runs, multiple bends, or branches.

One of the main advantages of inline fans is their space-saving design. Since they are installed within the ductwork, they do not require additional floor or wall space, making them ideal for situations where space is limited. Inline fans are also relatively easy to install, as they can be connected directly to the existing ductwork without the need for extensive modifications.

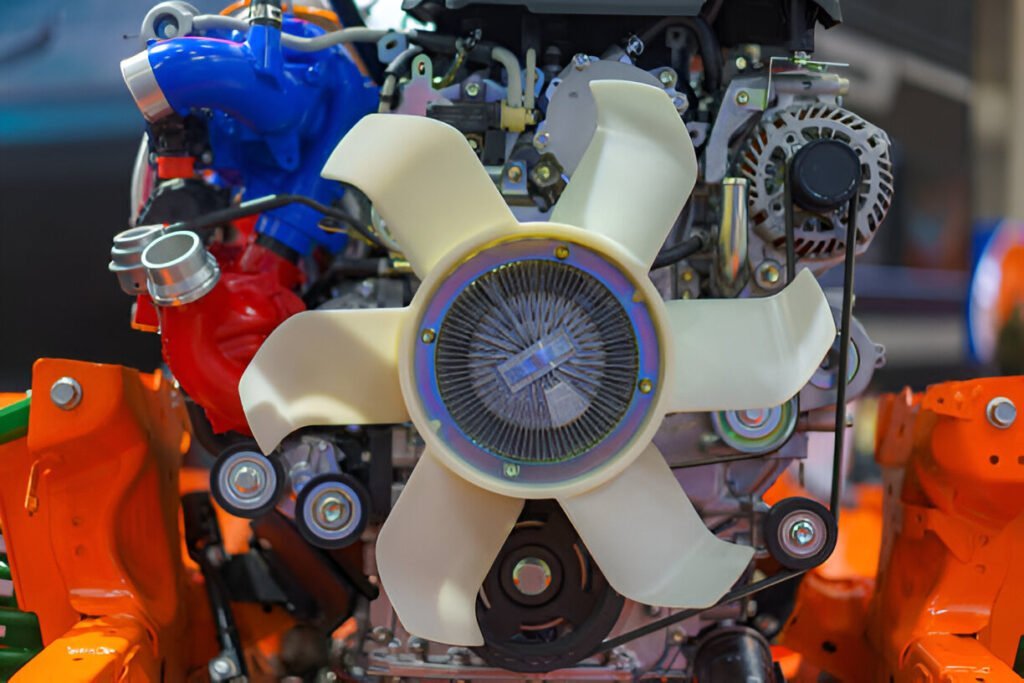

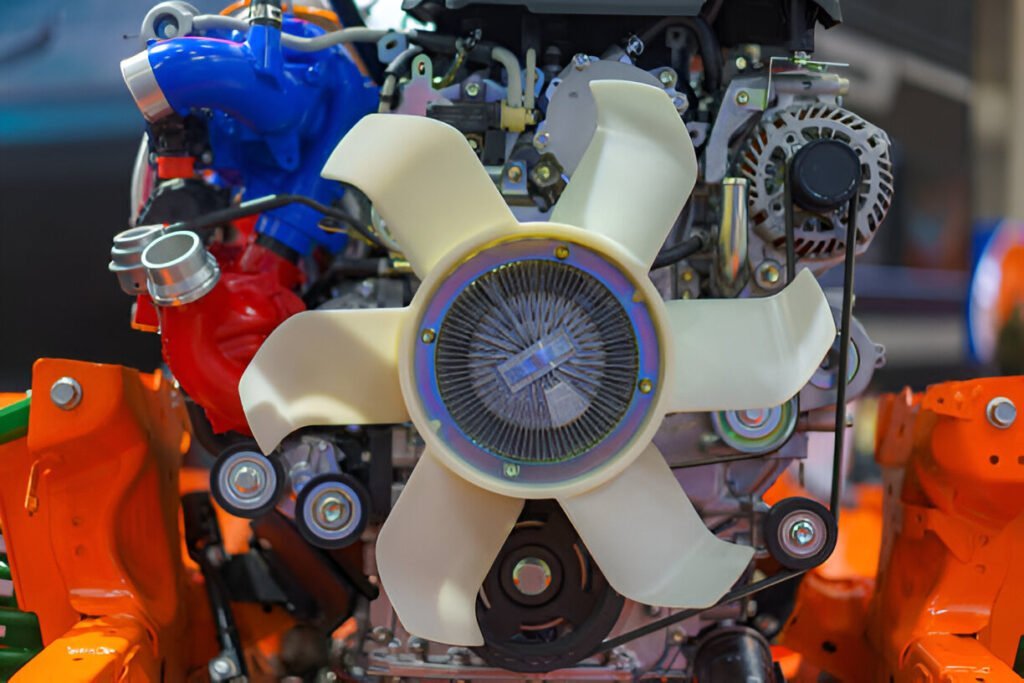

Propeller fans, also known as axial fans, moves air in a straight line along the axis of the fan. They consist of a propeller-like blade assembly mounted within a cylindrical housing or venturi. Propeller fans are designed to move large volumes of air at relatively low pressures, making them suitable for applications requiring high airflow rates.

The blades of a propeller fan are typically made of lightweight materials such as aluminum or plastic, and their shape is optimized for efficient airflow. The number of blades can vary, with most designs featuring between 2 and 8 blades.

One of the main advantages of propeller fans is their compact design, which allows for easy installation in a variety of settings. They can be mounted on walls, ceilings, or ducts, depending on the specific application. Propeller fans are also relatively inexpensive compared to other types of HVAC fans, making them a cost-effective choice for many projects.

However, propeller fans have some limitations. They are not well-suited for applications requiring high static pressure, as their performance tends to decrease rapidly as the resistance to airflow increases. Additionally, propeller fans can be noisy, especially when operating at high speeds, which may be a concern in some environments.

Cross-flow fans, also known as tangential fans, are unique in their design and operation compared to other types of HVAC fans. They feature an elongated, cylindrical impeller that spans the entire width of the fan housing. This distinctive design allows cross-flow fans to produce a wide, uniform airflow across the length of the fan.

The impeller in a cross-flow fan consists of numerous blades arranged in a circular pattern. As the impeller rotates, air enters the fan from one side and is drawn through the blades, moving perpendicular to the axis of rotation. This airflow pattern is what gives cross-flow fans their name, as the air moves “across” the fan rather than being expelled axially or radially.

One of the key advantages of cross-flow fans is their ability to produce a consistent, evenly distributed airflow. This makes them ideal for applications that require a wide, uniform air curtain, such as air doors, air curtains, and HVAC systems in commercial buildings. The even airflow helps maintain a consistent temperature and prevents the infiltration of outside air, dust, or insects.

Cross-flow fans are also known for their quiet operation and compact size. The elongated design allows for a relatively large air output in a small footprint, making them suitable for installations with limited space. Additionally, the even distribution of air across the fan’s width reduces noise levels compared to other fan types.

Forward curved fans, also known as sirocco fans. The blades of these fans curve in the direction of rotation, allowing them to move large volumes of air at lower pressures. This design makes forward curved fans well-suited for applications requiring high airflow rates and low static pressure, such as air conditioning systems and air handlers.

One of the main advantages of forward curved fans is their compact size relative to their airflow capacity. This space-saving design allows for easier installation in tight spaces, making them a popular choice for residential and light commercial HVAC systems. Additionally, forward curved fans operate at lower speeds compared to other centrifugal fan types, resulting in quieter operation and reduced noise levels.

However, forward curved fans have some limitations. They are less efficient than other centrifugal fan designs, such as backward curved or airfoil fans, particularly at higher static pressures. This lower efficiency can lead to increased energy consumption and operating costs. Moreover, forward curved fans are more prone to overloading if the system resistance is lower than expected, which can cause the motor to draw excessive current and potentially lead to premature failure.

Backward curved fans, also known as backward inclined fans. These fans feature blades that curve away from the direction of rotation, allowing for efficient airflow and reduced noise levels. The unique blade design enables backward curved fans to handle high volumes of air with minimal turbulence, making them ideal for applications requiring consistent, stable airflow.

One of the key advantages of backward curved fans is their energy efficiency. The aerodynamic design of the blades minimizes the power required to move air, resulting in lower energy consumption compared to other fan types. This efficiency translates to cost savings for both residential and commercial HVAC systems, as well as reduced environmental impact.

Airfoil fans, also known as aerofoil fans. The blades of airfoil fans have a cross-sectional shape similar to that of an airplane wing, which allows for smooth, turbulence-free airflow. This design minimizes energy loss and noise generation, making airfoil fans one of the most efficient and quiet options available.

The unique shape of airfoil blades allows them to maintain optimal performance across a wide range of operating conditions. As air moves over the curved surface of the blade, it creates a pressure difference between the upper and lower surfaces, generating lift and reducing drag. This aerodynamic design enables airfoil fans to move large volumes of air with minimal power consumption, resulting in lower operating costs and increased energy efficiency.

Airfoil fans are commonly used in applications that require high airflow rates and pressure, such as large commercial and industrial HVAC systems. They are particularly well-suited for handling clean air in environments where energy efficiency and low noise levels are prioritized. Some common applications include air handling units, cooling towers, and large-scale ventilation systems in buildings like hospitals, schools, and office complexes.

In residential settings, HVAC fans are essential components of heating, ventilation, and air conditioning systems. They circulate conditioned air throughout the home, ensuring even temperature distribution and improved indoor air quality. Commonly used residential HVAC fans include:

Commercial buildings, such as offices, retail stores, and restaurants, rely on HVAC fans to create pleasant and productive environments for occupants. These fans are integral to larger, more complex HVAC systems designed to handle the unique needs of each space. Typical commercial HVAC fan applications include:

In industrial settings, HVAC fans play a vital role in maintaining proper ventilation, temperature control, and air quality. These fans are often larger and more robust to handle the demands of manufacturing processes, chemical handling, and other industrial activities. Key industrial HVAC fan applications include:

When choosing an HVAC fan, consider factors such as airflow requirements, static pressure, noise levels, energy efficiency, and the specific application (e.g., exhaust, ventilation, or air conditioning).

A typical HVAC system has two main fans: the supply fan, which pushes conditioned air through the ducts and into the building, and the exhaust fan, which removes stale air from inside. Some larger systems may have additional fans for specific zones or functions.