Can Industrial Fans Overheat

Explore the factors that can cause industrial fans to overheat and learn preventative maintenance tips.

Read More

Fan are ubiquitous in modern life, found in everything from personal electronics to industrial machinery. Understanding the components that make up these essential devices is crucial for professionals involved in their design, manufacture, and maintenance.

In this blog post, we will delve into the intricate parts that work together to create a functional fan, exploring their roles and the materials used in their construction.

The electric motor is the heart of any electric fan. It converts electrical energy into mechanical energy, which in turn rotates the fan blades to generate airflow.

Fan motors come in different types, such as AC induction motors or DC brushless motors. The motor typically consists of a stator (the stationary part) and a rotor (the rotating part) that work together to create the magnetic field necessary for rotation.

The back cover, also known as the motor housing, is the protective casing that encloses the electric motor.

The back cover is usually made of durable materials like plastic or metal and may include vents to allow for proper airflow and cooling of the motor.

Ball bearings are small, spherical bearings that help to reduce friction between moving parts in the fan’s motor and blade assembly.

They consist of a series of metal balls held between two circular metal rings called races. The balls rotate smoothly within the races, allowing the fan blades and motor shaft to spin with minimal resistance.

The fan blades are the most visible and recognizable part of an electric fan. They are responsible for pushing the air and creating the desired airflow pattern.

Fan blades are typically made of lightweight, durable materials such as plastic or aluminum and are aerodynamically designed to move air efficiently.

The blade bracket, also known as the blade arm or blade iron, is the component that connects the fan blades to the motor shaft. It provides a secure and stable mounting point for the blades and ensures that they rotate in unison with the motor.

Blade brackets are typically made of metal for strength and durability and may be designed to allow for easy blade attachment or removal for cleaning or replacement.

The capacitor is an electrical component that helps to start and run the fan motor efficiently. It stores electrical energy and releases it as needed to provide an extra boost of power to the motor during startup or when the fan is operating under heavy load.

Capacitors also help to regulate the voltage and current flow to the motor, which can extend its lifespan and improve overall performance. In some fans, the capacitor is housed within the motor casing, while in others, it may be a separate component mounted nearby.

The wire guard, also called a safety grille or fan cage, is a protective barrier that surrounds the fan blades. Its primary purpose is to prevent accidental contact with the spinning blades, which can cause injury.

Wire guards are typically made of metal or plastic mesh and are designed to allow for adequate airflow while still providing a physical barrier.

In oscillating fans, the gearbox is responsible for converting the rotational motion of the motor into the back-and-forth oscillating motion of the fan head. It consists of a series of gears and shafts that work together to change the direction of the fan’s airflow periodically.

The gearbox is usually housed within the fan’s base or neck and may include components like the oscillator shaft, oscillator knob, and oscillator gears.

Most electric fans include switches and controls that allow the user to adjust the fan’s settings according to their preferences. These may include:

These controls are usually located on the fan’s body or base and may be in the form of buttons, knobs, or digital displays.

The power cord and wiring are the electrical components that supply power to the fan motor and other electrical parts. The power cord typically plugs into a standard wall outlet and may include a polarized or grounded plug for safety.

Inside the fan, wires connect the power cord to the motor, capacitor, switches, and other components.

Buy industrial fans in bulk and enjoy generous discounts, ensuring you experience guaranteed quality with zero risk.

The mounting bracket is a critical component of a ceiling fan, as it securely attaches the fan to the ceiling. It also houses the electrical connections and provides a stable base for the fan’s canopy and downrod.

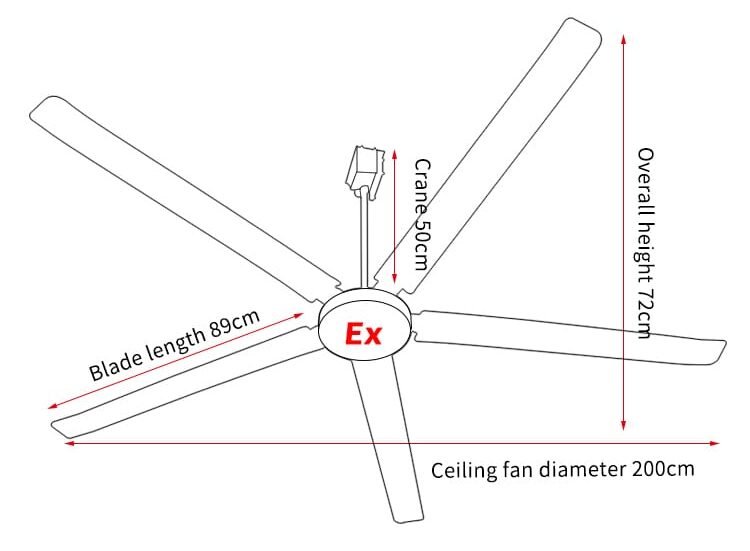

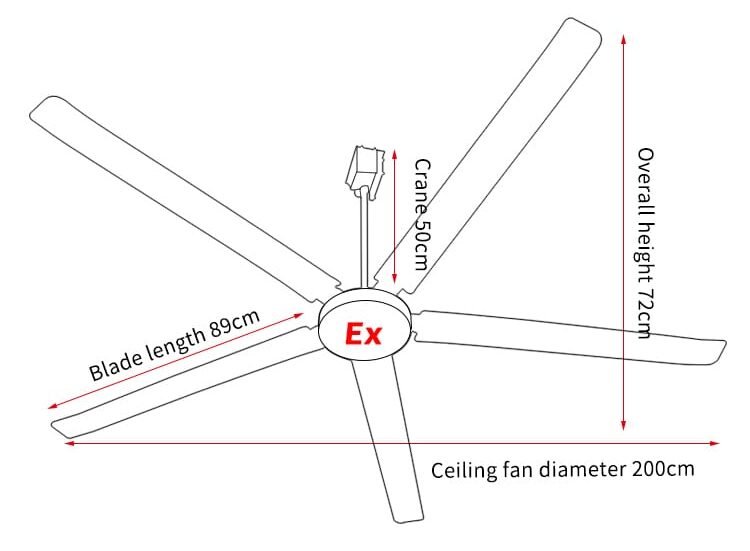

The downrod is a metal pipe that connects the mounting bracket to the fan’s motor housing. Downrods come in various lengths to accommodate different ceiling heights and room sizes. They also help to reduce wobbling and vibration by providing a secure connection between the mounting bracket and the fan’s motor.

In some cases, close-mount ceiling fans may not require a downrod and can be directly attached to the mounting bracket.

Blade brackets, also known as blade irons or blade arms, are the metal attachments that connect the fan blades to the motor housing. These brackets are typically made of durable materials like cast iron or steel to ensure a strong and stable connection.

Many ceiling fans feature pull chains, which allow users to control the fan’s speed and lighting functions manually. These chains typically hang down from the fan’s switch housing and are connected to internal switches.

Many ceiling fans come with integrated light kits, which provide both illumination and air circulation in a single unit. These light kits are typically located at the bottom of the fan and can feature various styles, such as bowl lights, branched lights, or globe lights.

| Component | Common Materials |

|---|---|

| Fan Blades | – Plastic (ABS, polypropylene) – Metal (aluminum, steel) – Wood (plywood, MDF, solid wood) – Fiberglass |

| Electric Motor | – Steel (laminated or cast iron core) – Copper (windings) – Aluminum (housing, end caps) – Plastic (insulation, connectors) |

| Motor Housing | – Plastic (ABS, polypropylene) – Metal (aluminum, steel) – Rubber (vibration damping) |

| Mounting Bracket | – Metal (steel, aluminum) – Plastic (high-impact polymers) |

| Gearbox | – Metal (steel, brass) – Plastic (nylon, polyoxymethylene) |

| Ball Bearings | – Steel (chromium steel, stainless steel) – Ceramic – Plastic (for low-load applications) |

| Capacitor | – Aluminum (electrolytic capacitor) – Plastic film (polyester, polypropylene) – Ceramic |

| Wiring & Connectors | – Copper (electrical wiring) – Plastic (insulation, connectors) – Rubber (insulation, grommets) |

| Switches & Controls | – Plastic (housing, buttons) – Metal (contacts, springs) – Rubber (seals, gaskets) |

| Wire Guard | – Metal (steel, aluminum) – Plastic (polypropylene, nylon) |

| Downrod (Ceiling Fans) | – Metal (steel, aluminum) – Wood |

| Light Kit (Ceiling Fans) | – Glass (shades, covers) – Plastic (shades, covers, housing) – Metal (housing, trim, heat sinks) |

A typical fan has nine main parts: motor, capacitor, blades, wire guard, back cover, gearbox, switch, oscillator knob, and power cord. Each part drives, controls, or protects airflow to keep you cool.

The motor converts electrical energy into mechanical motion to spin the rotor and fan blades, creating airflow. Common motor types include AC induction and DC brushless motors, each with different efficiency and noise characteristics.

The capacitor stores and releases electrical charge during startup to give the motor a boost and helps maintain steady voltage during operation, protecting the motor from overheating and ensuring smooth speed.

Fan blades can be made from plastic (lightweight and inexpensive), aluminum (durable and resistant to bending), or wood (quiet operation but heavier).

The oscillator knob controls the side-to-side movement of the fan head; pulling it enables oscillation while pushing it locks the fan in a fixed direction.

The back cover protects internal components such as the motor and gearbox, supports the structure, and provides ventilation to prevent overheating.

If the fan hums but the blades barely move or do not spin, the capacitor might be weak or damaged. Testing with a multimeter or replacing the capacitor can confirm the issue.

The wire guard prevents fingers or foreign objects from contacting rapidly spinning blades, ensuring user safety, especially around children and pets.