How to Calculate Centrifugal Fan Capacity

Learn the steps to accurately determine centrifugal fan airflow capacity using fan laws and performance curves.

Read More

In the vast world of industrial machinery, Centrifugal Fan serve as the unsung heroes, powering countless applications across various sectors. Two prominent types of fans, centrifugal fans and radial fans, are often mistaken for one another due to their similar appearances and functions.

This blog post aims to shed light on the key differences between centrifugal fans and radial fans, exploring aspects such as airflow direction, blade design, pressure, noise levels, and applications. By the end of this article, readers will have a clear understanding of the unique characteristics and advantages of each fan type, empowering them to make informed decisions when selecting the most suitable fan for their specific requirements.

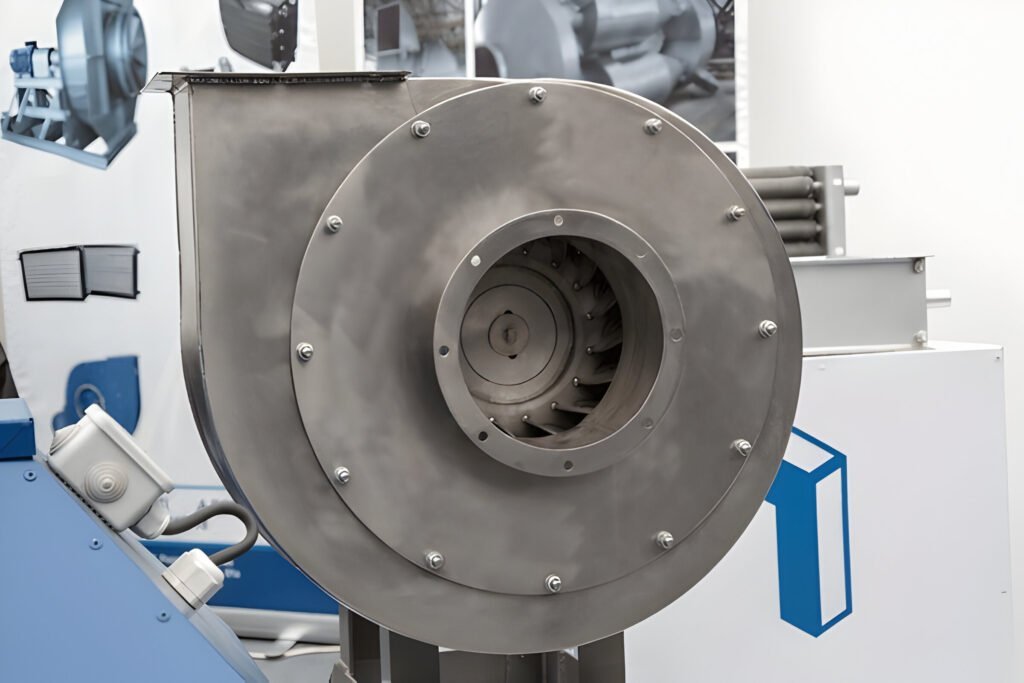

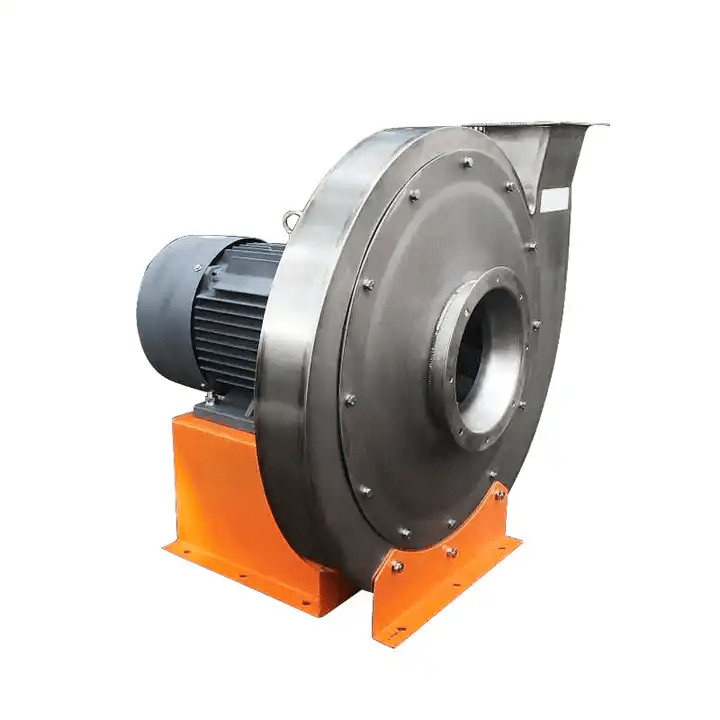

A centrifugal fan is a mechanical device designed to move air or other gases by utilizing the centrifugal force generated by a rotating impeller. The impeller, which consists of a series of blades mounted on a circular hub, is positioned within a spiral or scroll-shaped housing.

As the impeller rotates, it draws air into the center of the fan and accelerates it radially outward. The centrifugal force created by the rotating impeller causes the air to move perpendicular to the shaft, increasing its velocity and pressure. The spiral-shaped housing collects the air and directs it to the fan’s outlet, creating a continuous flow of high-velocity air.

Centrifugal fans are capable of generating high pressures and are well-suited for applications that require the movement of air against resistance, such as in air conditioning systems, industrial exhaust systems, and dust collection equipment. The blade design and housing geometry can be optimized for specific performance characteristics, such as pressure, flow rate, and efficiency.

A radial fan, also known as a paddle wheel fan, is a type of centrifugal fan that features a unique blade design. Unlike a typical centrifugal fan, which has forward-curved or backward-curved blades, a radial fan has straight blades that extend radially from the hub.

The straight blade design allows air to enter the fan axially and then be discharged radially, perpendicular to the intake direction. As the impeller rotates, the blades generate a centrifugal force that accelerates the air outward, creating a high-velocity airflow.

Radial fans are known for their ability to handle high-pressure applications and are often used in situations where air must be moved against significant resistance. They are commonly found in industrial processes, such as drying, conveying, and dust extraction systems.

While centrifugal fans and radial fans share similarities in their basic operating principles, they have distinct differences that make them suitable for different applications.

One of the primary differences between centrifugal fans and radial fans lies in the direction of airflow. Centrifugal fans draw air in parallel to the shaft and expel it perpendicularly, creating a 90-degree change in airflow direction. In contrast, radial fans draw air in axially, parallel to the shaft, and discharge it radially, maintaining the same airflow direction.

The blade design of centrifugal fans and radial fans differs significantly. Centrifugal fans typically feature forward-curved, backward-curved, or airfoil blades, depending on the specific application requirements. These blade designs affect the fan’s efficiency, pressure generation, and noise levels.

Radial fans, on the other hand, have straight or slightly curved blades that extend radially from the hub. This blade design allows for efficient airflow and pressure generation while minimizing turbulence and noise.

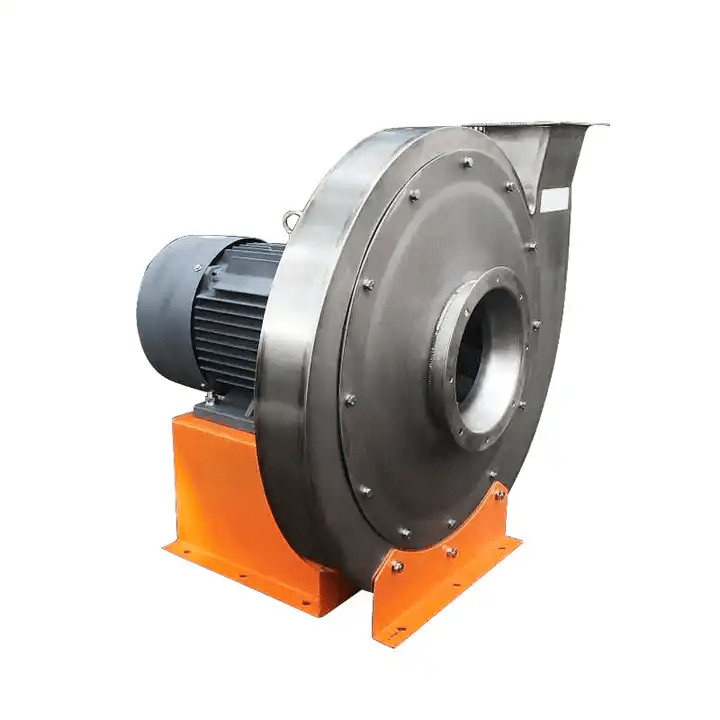

Buy the Industrial Stainless Steel Centrifugal Fan 9-19 now and enjoy discounts on purchases. Enjoy numerous savings and help your factory achieve efficient ventilation!

Centrifugal fans are known for their ability to generate higher pressures compared to radial fans. The centrifugal force created by the rotating impeller allows centrifugal fans to overcome greater resistance and move air through more complex ductwork systems.

Radial fans, while still capable of generating pressure, are typically used in applications that require lower pressure levels. They are more suitable for moving large volumes of air with minimal resistance.

Noise levels are another important consideration when choosing between centrifugal fans and radial fans. Centrifugal fans, particularly those with forward-curved blades, tend to generate higher noise levels due to the turbulence created by the airflow.

Radial fans, with their straight blade design and smooth airflow, generally operate with lower noise levels. This makes them preferable in applications where noise reduction is a priority, such as HVAC systems in residential or commercial buildings.

The distinct characteristics of centrifugal fans and radial fans make them suitable for different applications. Centrifugal fans are commonly used in industrial settings, such as dust collection systems, air pollution control, and material handling. They are also found in HVAC systems, particularly in applications that require higher static pressures.

Radial fans, on the other hand, are widely used in ventilation and cooling applications where large volumes of air need to be moved efficiently. They are commonly found in air conditioning units, refrigeration systems, and engine cooling for vehicles and generators.

Centrifugal fans use impellers to spin and create centrifugal force, pushing air outward from the center to the fan’s edges, producing high static pressure and steady airflow.

Centrifugal fans have forward-curved, backward-curved, or radial (straight) blades, each designed for different airflow and pressure characteristics. Radial fans specifically have straight blades for robust, heavy-duty usage.