What Is EC Centrifugal Fan

EC centrifugal fans are energy-efficient, electronically commutated fans designed for HVAC applications.

Read More

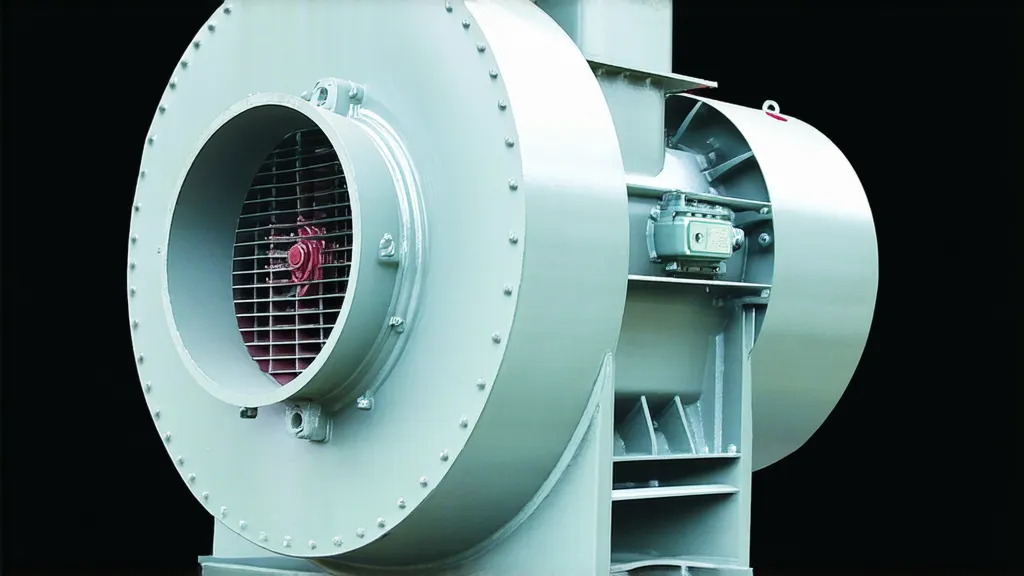

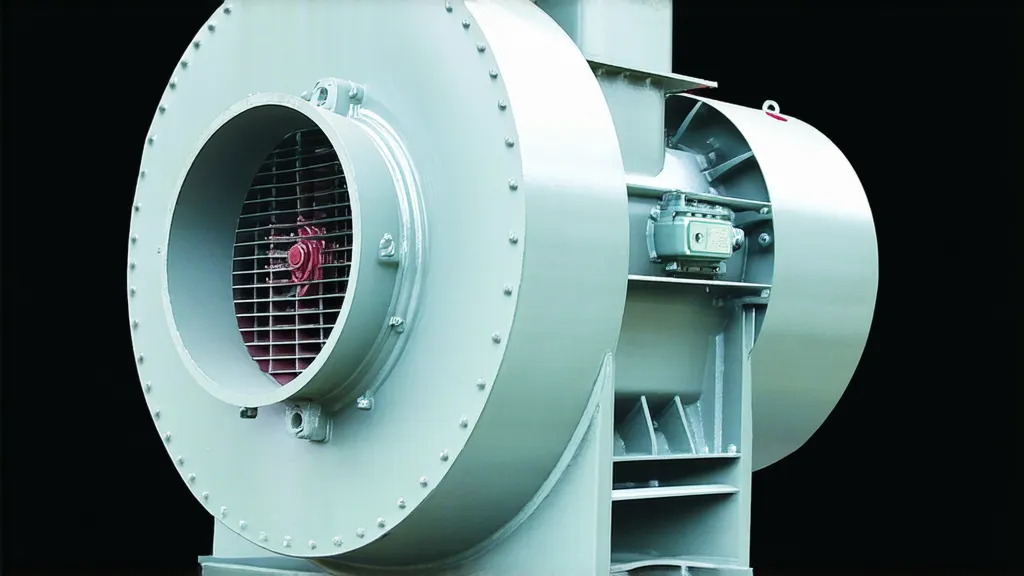

Centrifugal blowers are critical for many industrial processes, yet selecting the right type can be a daunting challenge.

With so many options like forward curved, backward inclined, radial, and airfoil designs, how can you be sure you’re choosing the optimal blower for your specific application? The wrong choice could lead to inefficiencies, increased energy costs, and even equipment failure.

In this blog post, we’ll break down the key types of centrifugal blowers. From single thickness blades to multistage designs, you’ll gain the knowledge to confidently select the ideal blower to keep your operations running smoothly and efficiently.

Forward curved blowers, also known as squirrel cage blowers, have blades that curve in the direction of the impeller rotation. This design allows for a high flow rate while operating at a relatively low speed, making them well-suited for applications that require high volumes of air at lower pressures.

Backward inclined centrifugal blowers have impeller blades that slope away from the direction of rotation. This design allows for higher air pressure generation compared to forward curved designs. There are three main types of backward inclined blowers:

Radial blowers, also known as paddle wheel blowers, feature straight radial blades that are arranged perpendicular to the axis of rotation. As the impeller rotates, these blades push the air outward from the center, creating airflow. The air is then collected by a scroll-shaped housing and discharged through an outlet.

Radial tip blowers are a variation of the radial design, featuring a small forward curved blade extension at the outer edge of each radial blade. This blade tip helps guide airflow and improves efficiency compared to standard radial blowers.

The added blade tip also reduces noise levels and provides a slight boost in flow rate. Radial tip blowers are suitable for applications that require a balance between the high-pressure capabilities of radial blades and the efficiency of backward inclined designs.

Inline centrifugal blowers have an axial inlet and axial outlet, with the impeller positioned between the two. This configuration allows for a compact, space-saving design that can be easily integrated into ducting systems.

Inline blowers typically use either backward inclined or airfoil blades for efficient operation. They are well-suited for applications with limited installation space, such as air conditioning units, ventilation systems, and process cooling.

Airfoil centrifugal blowers utilize blades with a cross-sectional shape similar to an aircraft wing. This aerodynamic profile minimizes turbulence and improves efficiency compared to other blade designs.

Airfoil blowers can achieve high flow rates and pressures while maintaining optimal energy efficiency. They are commonly used in applications that demand superior performance, such as high-tech manufacturing, clean room ventilation, and advanced HVAC systems.

Volute centrifugal blowers feature a spiral-shaped housing that collects air from the impeller and gradually expands it, converting velocity pressure into static pressure. This unique design allows for efficient operation and high-pressure capabilities.

Volute centrifugal blowers are well-suited for applications requiring high pressures, such as pneumatic conveying, aeration, and vacuum systems. The volute housing shape enables optimal pressure recovery and minimizes energy losses.

Plug centrifugal blowers, also known as tubular centrifugal blowers, have a distinctive cylindrical housing with an inlet on one end and the discharge on the other. The impeller is mounted in the center of this tubular housing.

The plug design offers a compact footprint, making these blowers ideal for space-constrained applications. They are commonly used in air knife drying, cooling, and ventilation systems where moderate pressures are required.

Multistage centrifugal blowers consist of two or more impellers arranged in series, allowing them to generate higher pressures than single-stage blowers. Each stage increases the pressure incrementally, resulting in a cumulative pressure rise.

By utilizing multiple stages, these blowers can overcome significant pressure differentials and are used in applications such as high-pressure pneumatic conveying, high vacuum systems, and multi-stage compression processes. The number of stages can be customized based on the specific pressure requirements of the application.